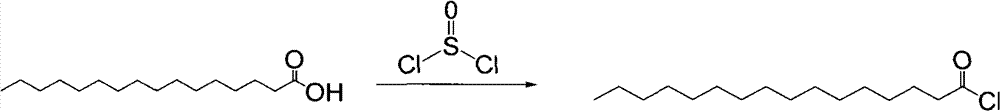

Method for preparing palmitoyl chloride

A technology of palmitoyl chloride and palmitic acid, which is applied in the field of palmitoyl chloride preparation, can solve the problems of high energy consumption and high recovery cost of distilling thionyl chloride, difficulty in separating palmitoyl chloride, and high reaction yield, so as to achieve easy industrial production and avoid The effect of a large amount of use and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of palmitoyl chloride: add palmitic acid (10mol, 2564g) and thionyl chloride (20mol, 2379g) into a magnetic stirring reaction kettle, then add 5ml N, N-dimethylformamide, heat to 60°C and stir for 1.5 hour; after the reaction finished, the reactant in the magnetic stirring reactor was poured into the distiller, 65 ℃ vacuum rotary evaporation, the pressure control in the distiller was 0.08Mpa in vacuum degree, and reclaimed thionyl chloride condensate, finally 2692g of colorless palmitoyl chloride liquid was obtained, the content of palmitoyl chloride was 97.0%, and the yield was 95%.

Embodiment 2

[0024] The preparation method of palmitoyl chloride: add palmitic acid (10mol, 2564g) and thionyl chloride (20mol, 2379g) into a magnetic stirring reaction kettle, then add 5ml N,N-dimethylformamide, heat to 75°C and stir to react 2 hours; after the reaction, the reactant in the magnetic stirring reactor was poured into the distiller, 80 DEG C vacuum rotary evaporation, the pressure in the distiller was controlled at a vacuum degree of 0.08Mpa, and the thionyl chloride condensate was recovered, Finally, 2692g of colorless palmitoyl chloride liquid was obtained, the content of palmitoyl chloride was 97.0%, and the yield was 95%.

Embodiment 3

[0026] The preparation method of palmitoyl chloride: add palmitic acid (10mol, 2564g) and thionyl chloride (30mol, 3569g) into a magnetic stirring reaction kettle, then add 5ml N,N-dimethylformamide, heat to 75°C and stir to react 2 hours; after the reaction, pour the reactant in the magnetic stirring reactor into the distiller, 90 DEG C vacuum rotary evaporation, the pressure in the distiller is controlled at a vacuum degree of 0.08Mpa, and the thionyl chloride condensate is recovered, Finally, 2693g of colorless palmitoyl chloride liquid was obtained, the content of palmitoyl chloride was 98.2%, and the yield was 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com