Liquid crystal aligning agent, liquid crystal alignment layer and liquid crystal display device

A technology of liquid crystal alignment agent and polyamic acid, applied in liquid crystal materials, instruments, optics, etc., to achieve good long-term reliability and low ion density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

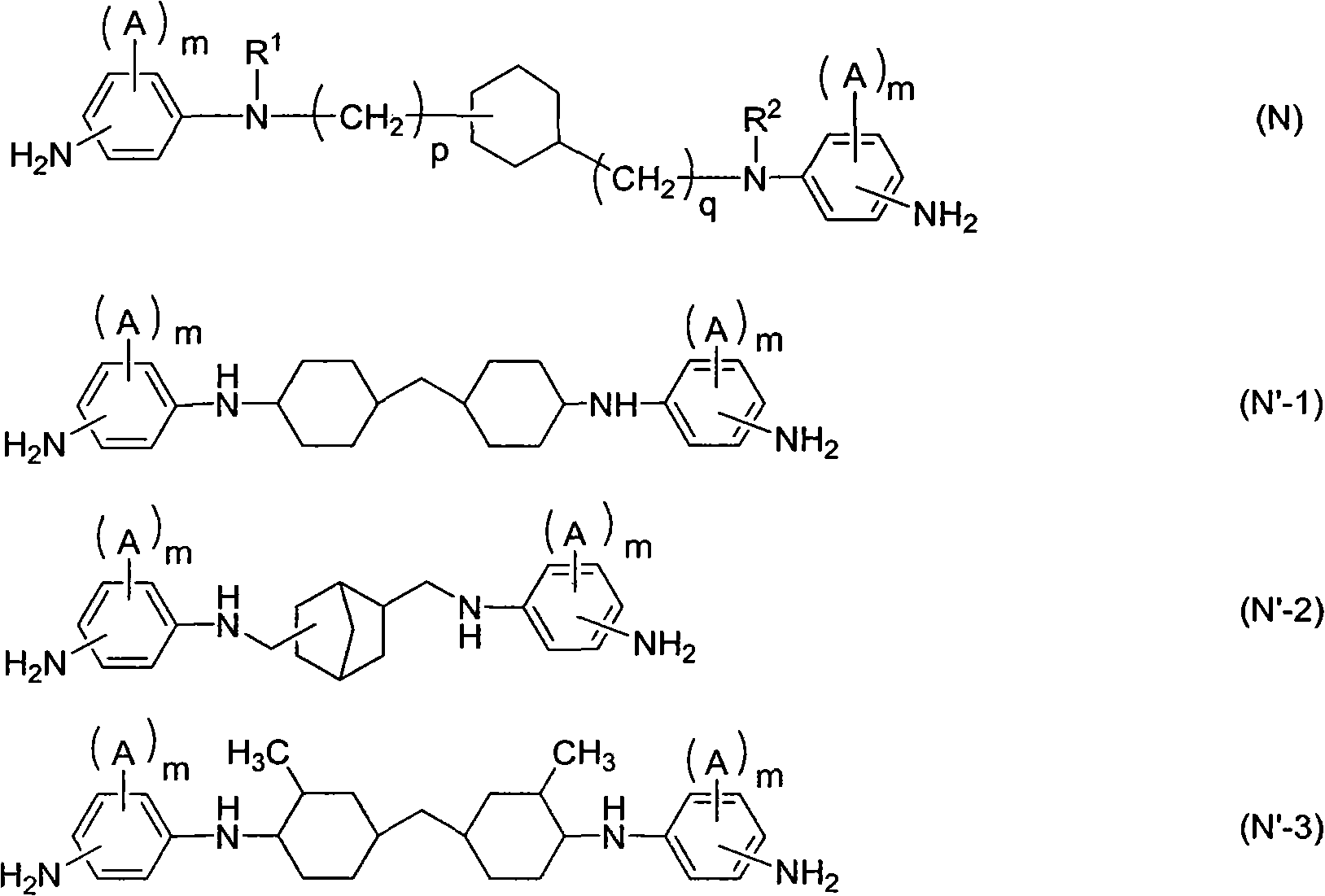

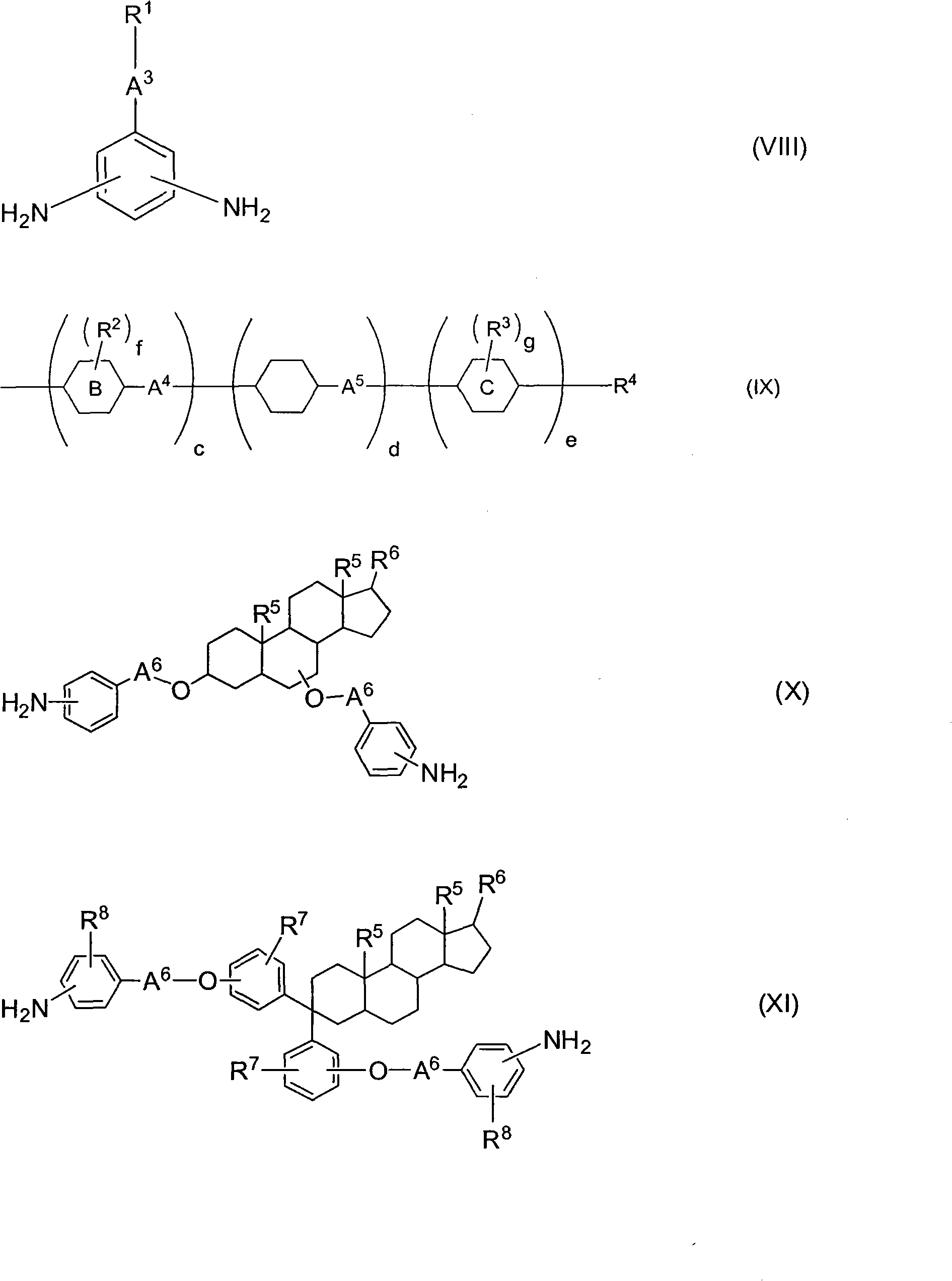

[0213]Hereinafter, the present invention will be described by way of examples. In addition, the compounds used in Examples are as described below.

[0214]

[0215] Anhydride (1): pyromellitic dianhydride

[0216] Anhydride (19): 1,2,3,4-cyclobutanetetracarboxylic dianhydride

[0217] Anhydride (23): 1,2,3,4-butanetetracarboxylic dianhydride

[0218] Anhydride (25): 1,2,4,5-cyclohexanetetracarboxylic dianhydride

[0219]

[0220] Diamine (N-1): N,N'-bis(4-aminophenyl)cyclohexane-1,2-diamine

[0221] Diamine (V-1): 4,4'-diaminodiphenylmethane

[0222] Diamine (V-7): 4,4'-diamino-1,2-diphenylethane

[0223] Diamine (VI I-2): 1,3-bis(4-(4-aminophenylmethyl)phenyl)propane

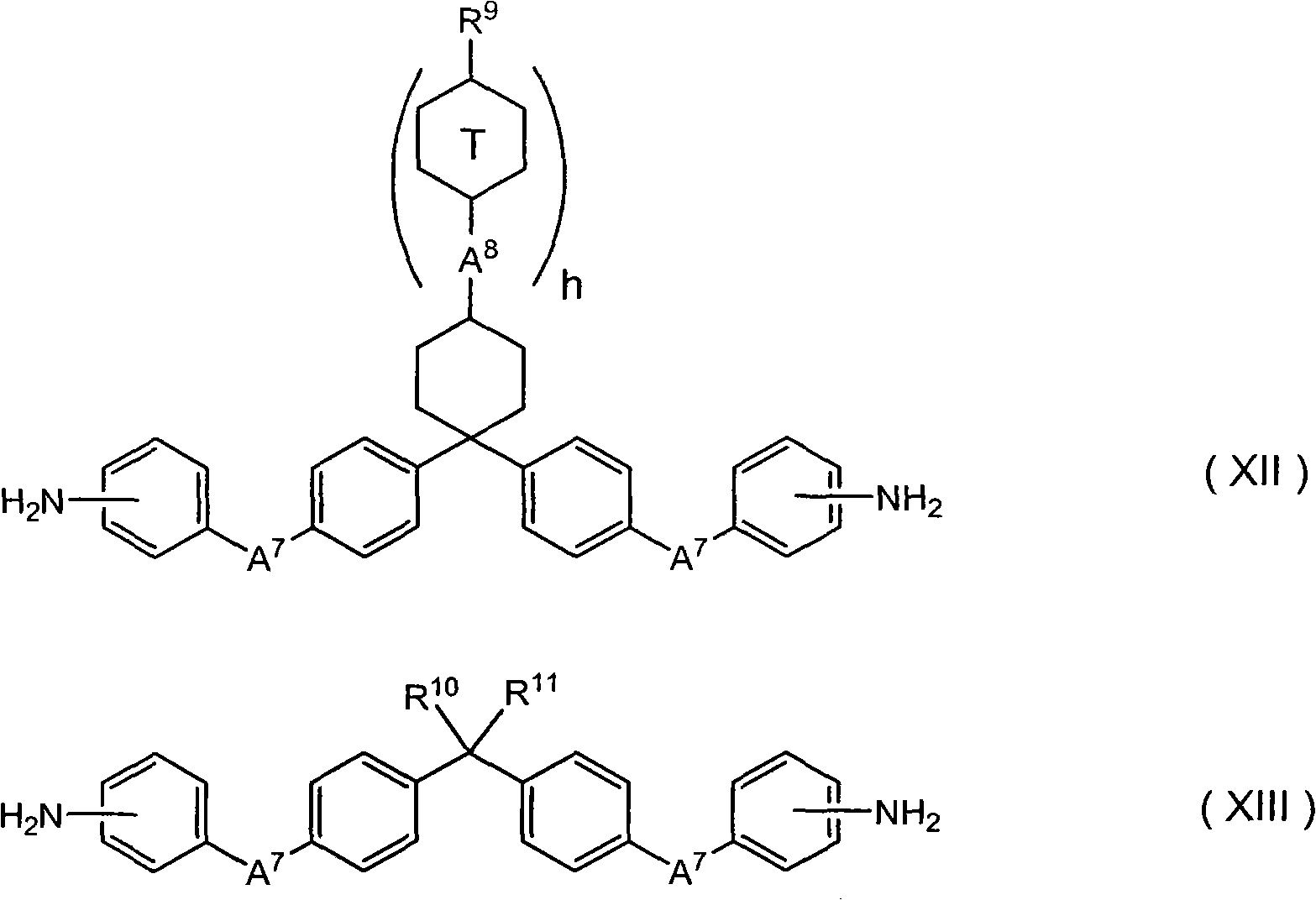

[0224] Diamine (XI I-2-1) (R 29 = n-heptyl): 1,1-bis(4-(4-aminophenylmethyl)phenyl)-4-n-heptylcyclohexane

[0225] Diamine (XII-4-1) (R 30 = n-pentyl): 1,1-bis(4-(4-aminophenoxy)phenyl)-4-(trans-4-n-pentylcyclohexyl)cyclohexane

[0226]

[0227] NMP: N-methyl-2-pyrrolidone

[0228] BC: Butyl ce...

Synthetic example 1

[0231] 3.532 g of diamine (N-1) and 50.0 g of dehydrated NMP were added to a 100 mL four-necked flask equipped with a thermometer, a stirrer, a raw material inlet, and a nitrogen gas inlet, and they were stirred and dissolved under a dry nitrogen stream. Next, 1.300 g of compound (1), 1.169 g of compound (19), and 24.0 g of dehydrated NMP were added, and reacted at room temperature for 30 hours. When the reaction temperature rises during the reaction, the reaction temperature is suppressed to about 70° C. or lower to allow the reaction. Then, 20.0 g of BC was added to the resulting solution to obtain a polyamic acid solution having a concentration of 6% by weight. This polyamic acid is referred to as PA1. The weight average molecular weight of PA1 was 108800.

[0232] The weight-average molecular weight of polyamic acid is obtained by the following method: utilize phosphoric acid-DMF mixed solution (phosphoric acid / DMF=0.6 / 100: weight ratio) to dilute the obtained polyamic a...

Synthetic example 2~10

[0234] Except having changed tetracarboxylic dianhydride and diamine as shown in Table 1, polyamic-acid solution (PA2) - (PA10) was prepared according to the synthesis example 1. The results including Synthesis Example 1 are summarized in Table 1.

[0235]

[0236]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com