Stone paper film forming device and technology

A film-forming equipment and stone paper technology, applied in paper, papermaking, special paper, etc., can solve the problems of heavy weight of stone paper, large safety hazards, and hidden dangers of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

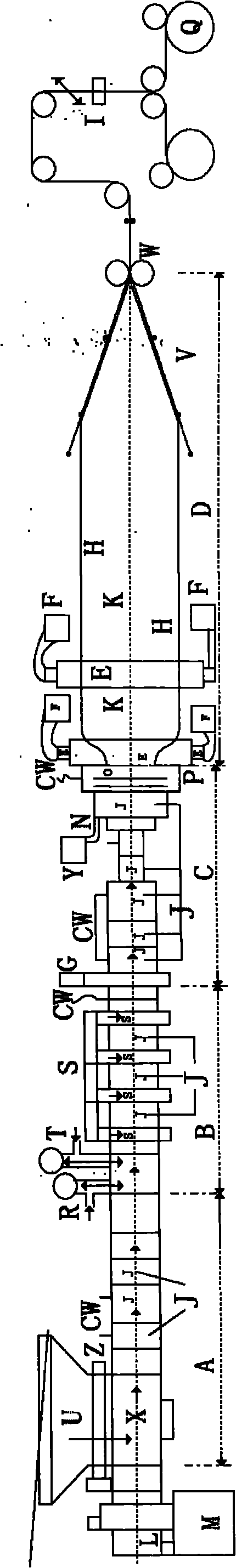

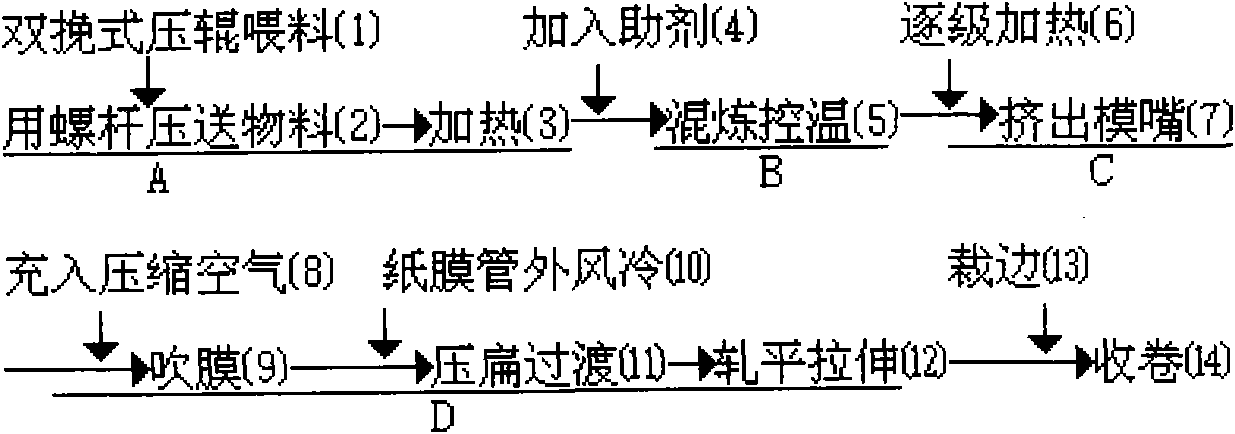

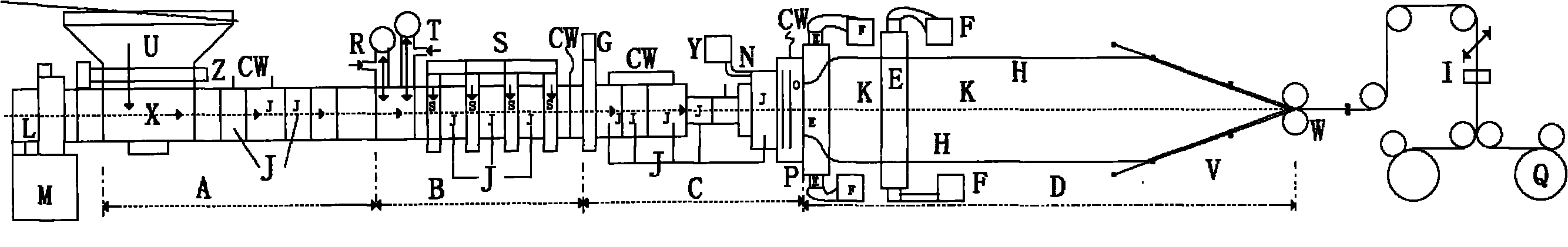

[0026] Such as figure 1 , figure 2 As shown, a stone paper film forming equipment and process is composed of an extruder and a film blowing device. The extruder and the film blowing device are horizontal and horizontal; the extruder is 6 meters long and divided into three sections: front, middle and back. The temperature control mixing section, the rear section C is the heating and melting extrusion section; each section of the entire screw barrel has a heater J and a temperature detection device CW, which can automatically adjust the temperature and control respectively; the film blowing device includes a compressor Y and a compressed air filling The inlet port K, the blower F and the air-cooled air ring E are composed of a V-shaped transition frame for gradually flattening and flattening, and a pulling and stretching flattening roller shaft W.

[0027] Heating the natural inorganic mineral powder, adding additives, through modification, adding polyethylene and polypropyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com