Secondary vertical rotating construction method for arch rib of long-span steel arch bridge

A construction method and large-span technology, applied in the direction of arch bridges, bridges, bridge forms, etc., can solve problems such as difficult to guarantee welding quality, difficult to install in place, difficult to implement construction plans, etc., to improve construction quality, reduce construction risks, reduce The effect of the amount of support work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

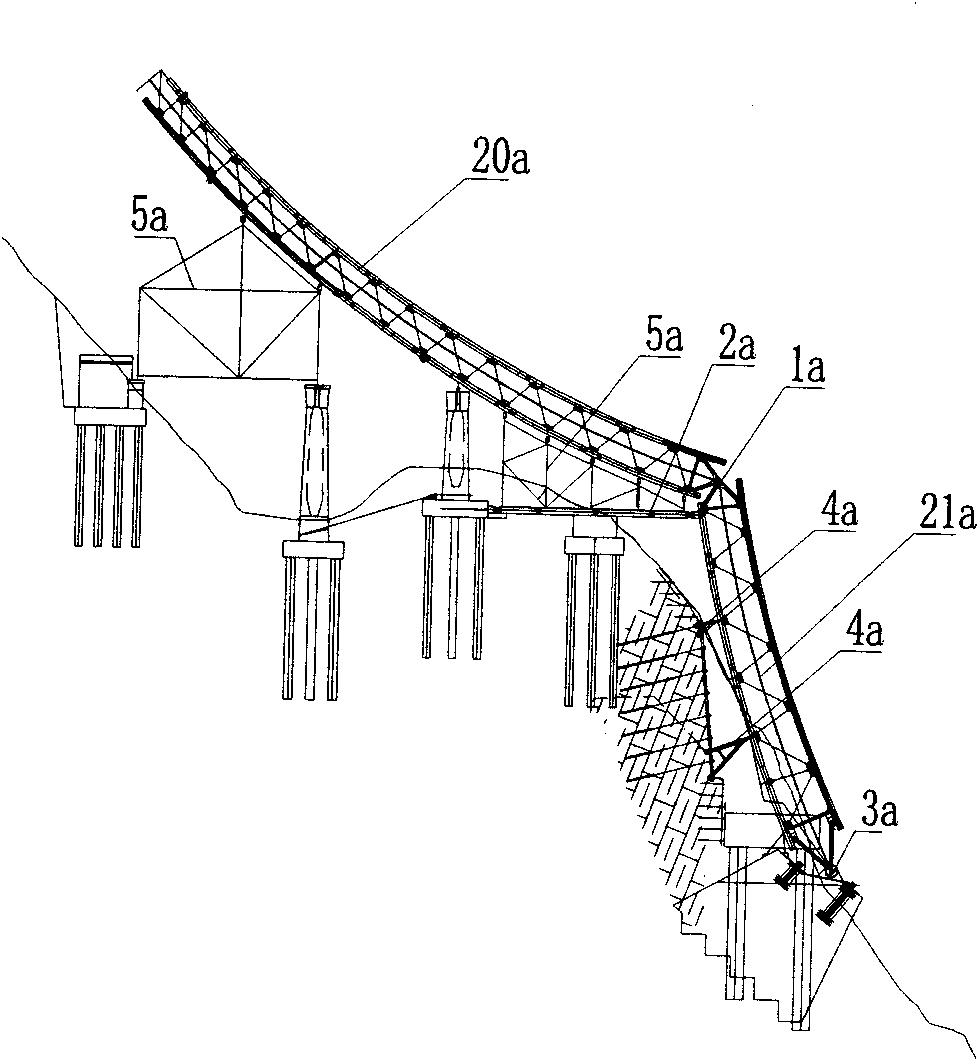

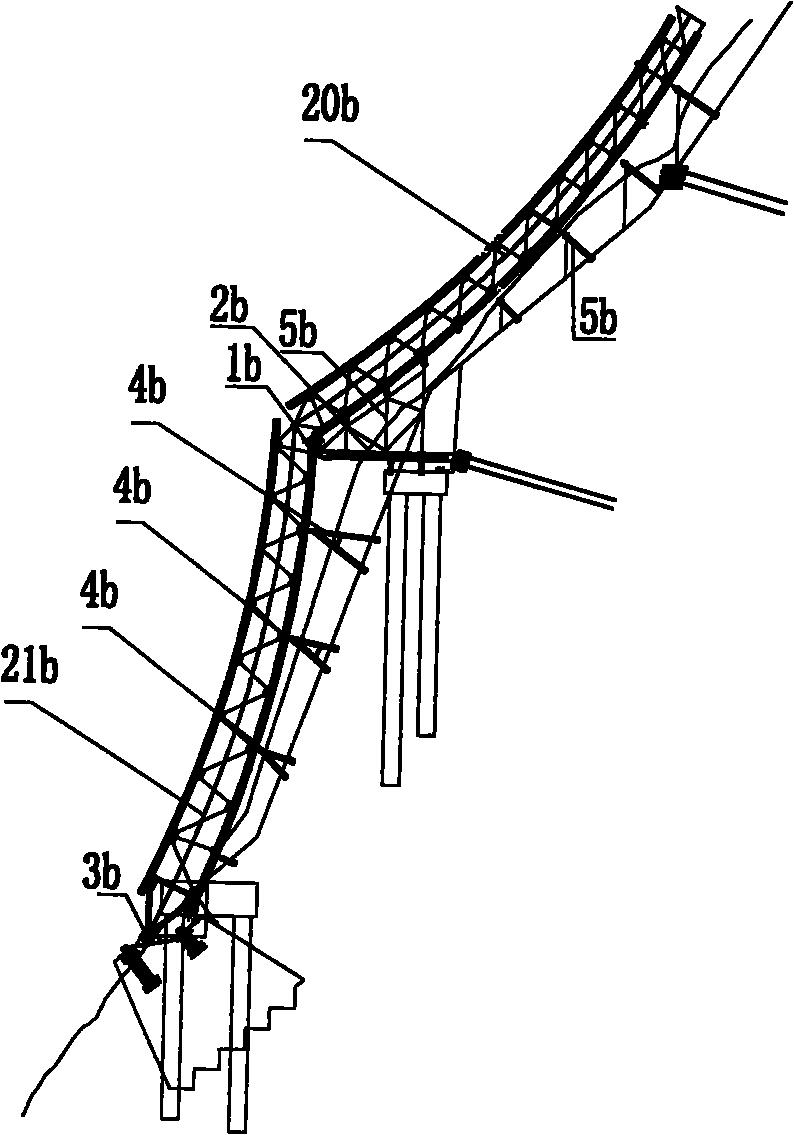

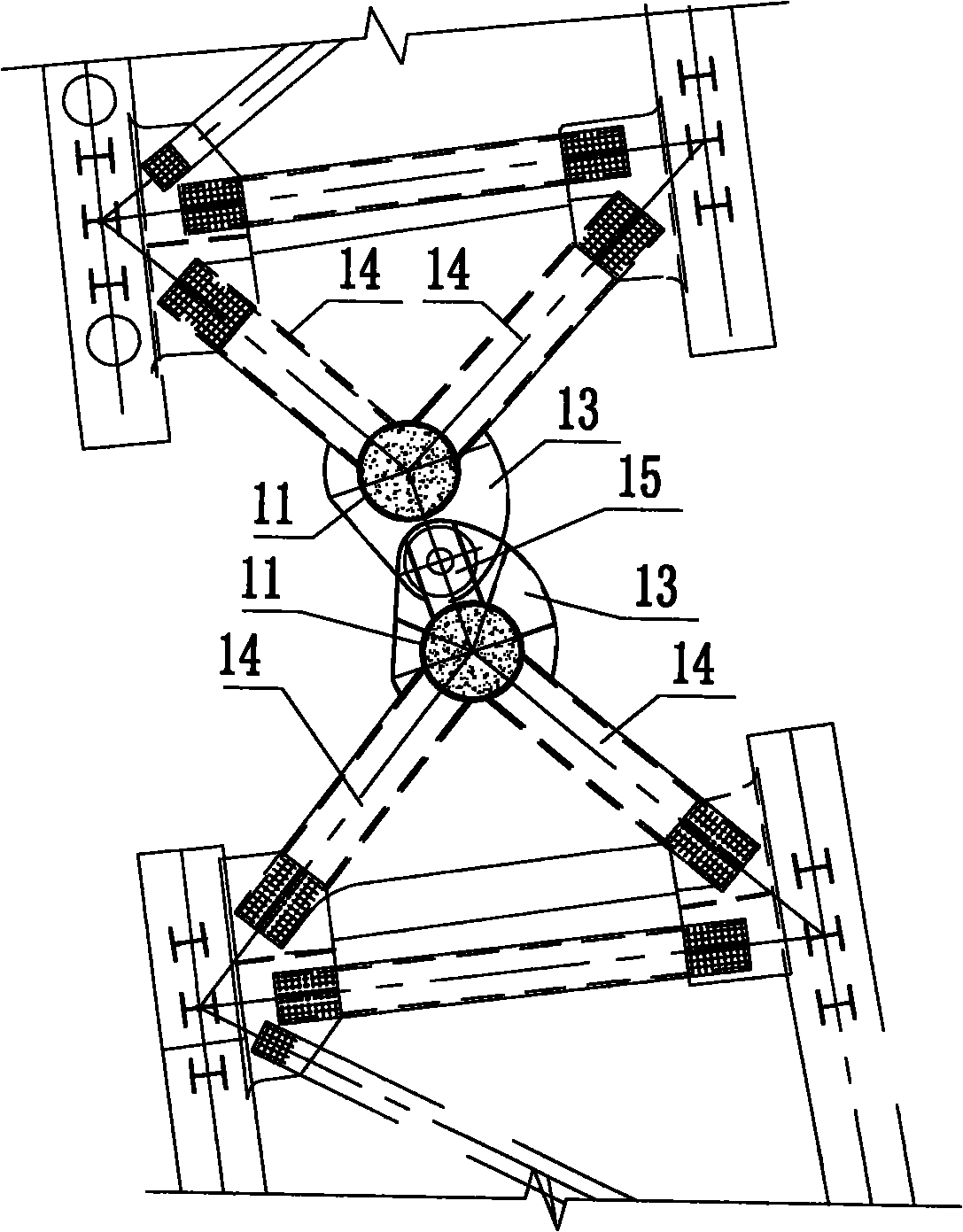

[0036] This embodiment has a total length of 528.1m and a main span of 342m. It is a reinforced concrete arch bridge with a stiffened frame. There are 2 arch ribs in the whole bridge. The arch ribs are all inwardly inclined at 6.8°, which is a basket arch structure. In order to make full use of the "V"-shaped valleys on both sides to build construction supports, the arch rib is divided into upper and lower sections, which are connected by a middle hinge. The lower section of the arch rib is tilted back 65° along the designed arch axis, basically parallel to the mountain, and the upper section of the arch rib is on the basis of which the left bank is tilted back 65°, and the right bank is tilted back 55°.

[0037] figure 1 , figure 2 They are the assembly drawings of the left and right bank arch ribs respectively, as shown in figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com