Displacement sensor

A displacement sensor and shell technology, applied in the field of displacement sensors, can solve problems such as adding sensors, complex pedal structure, and car space restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

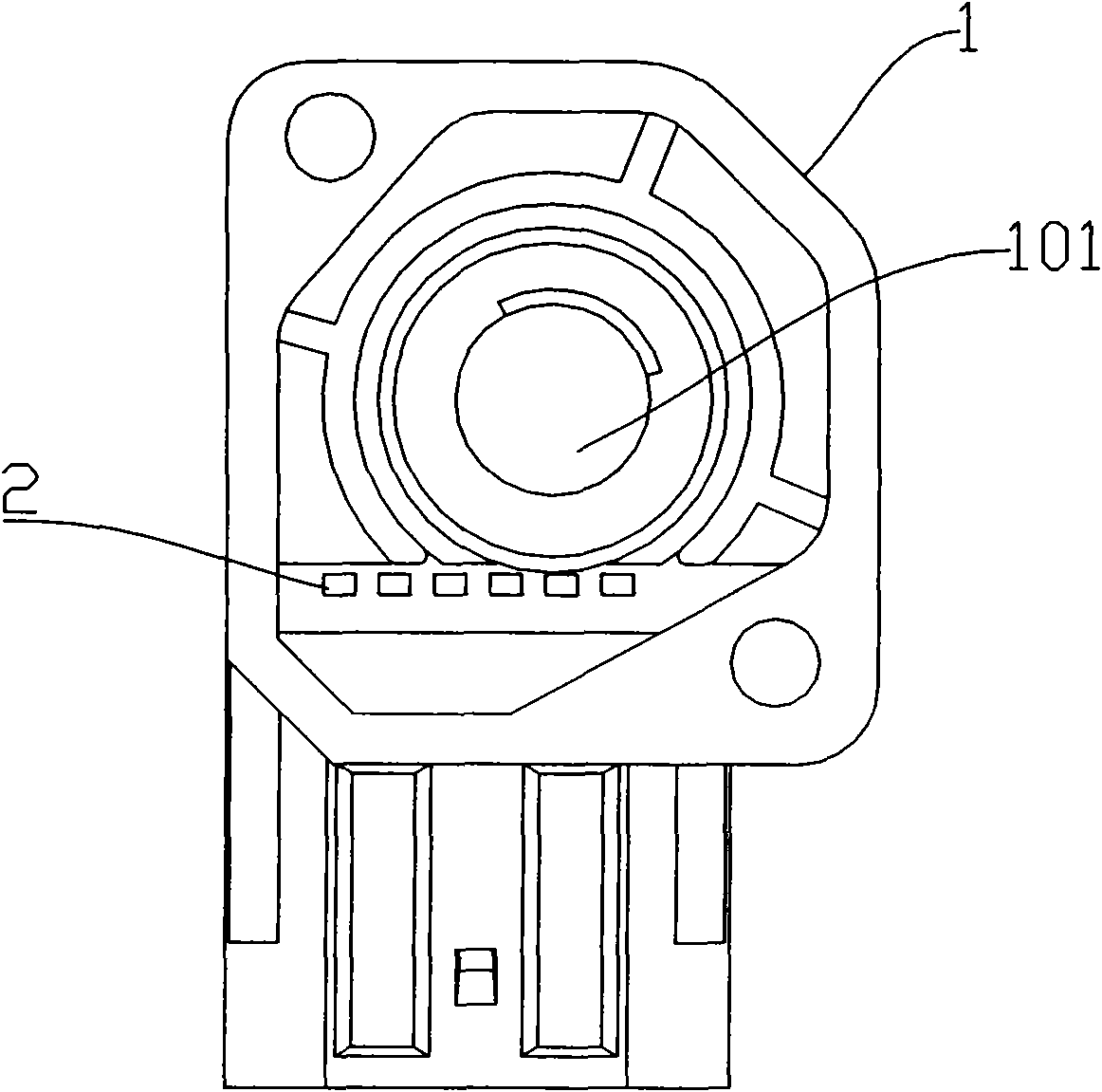

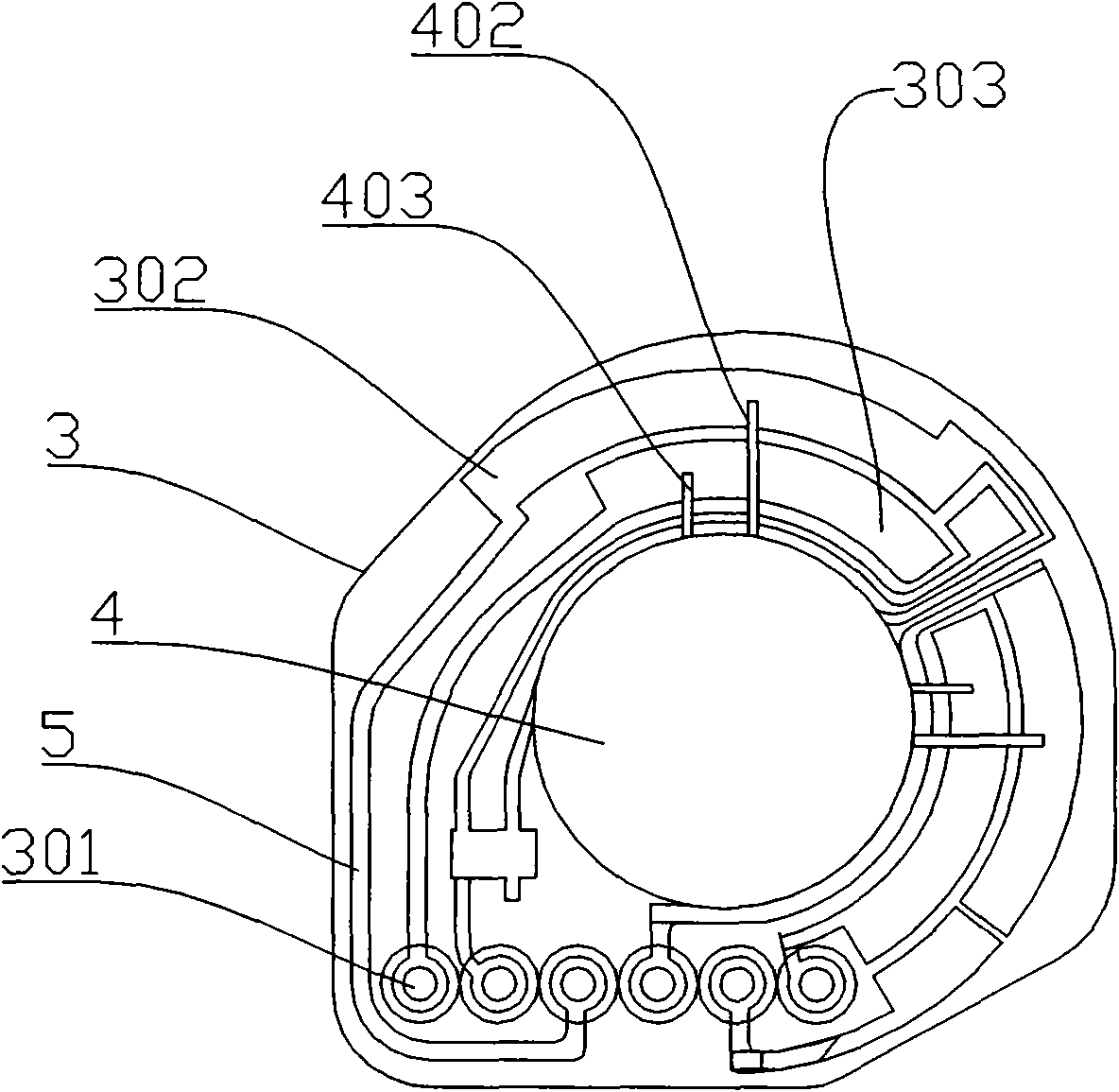

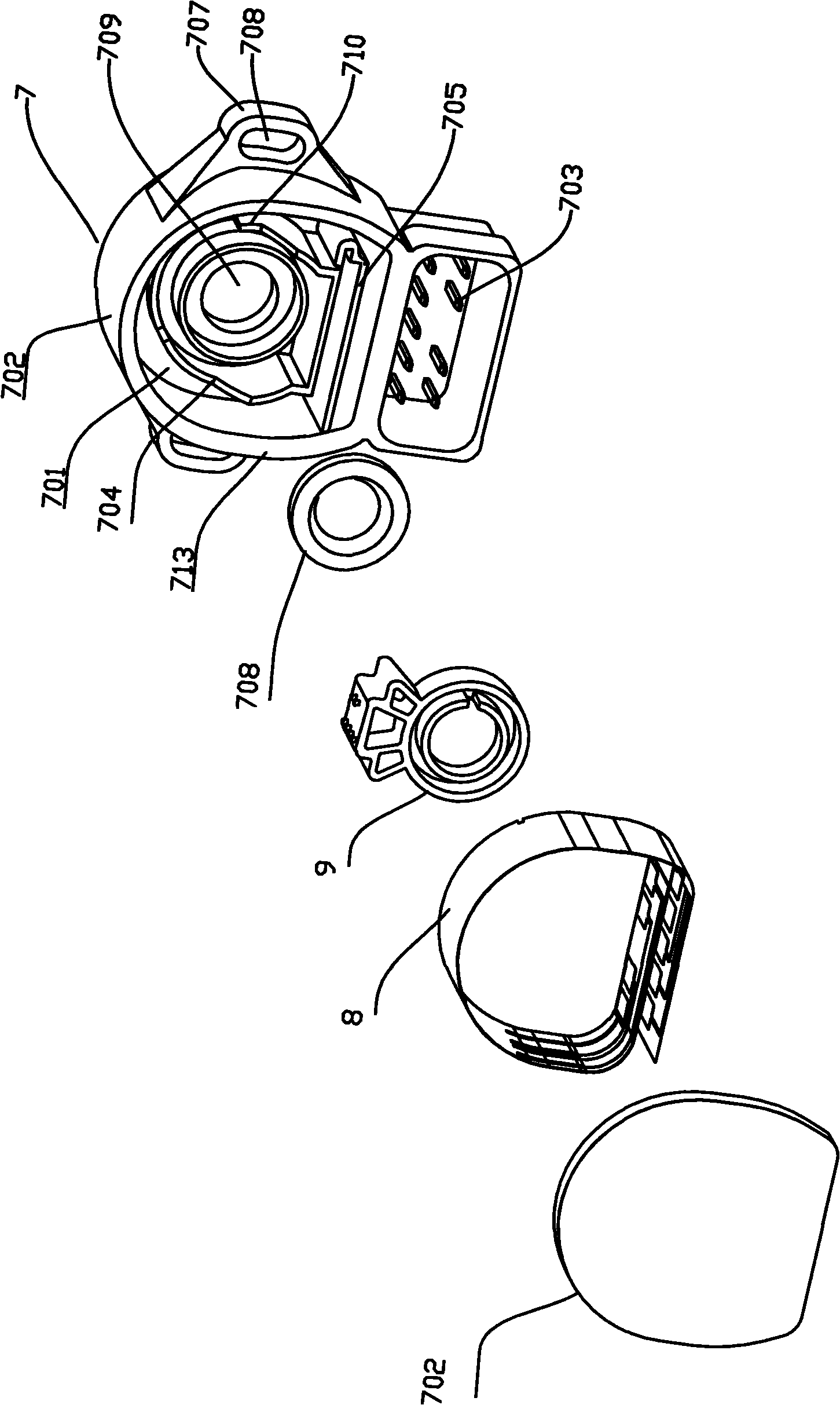

[0080] Such as image 3 , Figure 4 , Figure 5 As shown, the displacement sensor includes a housing 7, a circuit board 8, and a rotating shaft 9. The housing 7 includes a housing 713 with a cavity 701 and an end cover 706. The housing 713 has an arc portion 702, and the housing 713 is provided with 9 A metal terminal 703, one end of the metal terminal 703 can be connected to an external wire, and the other end extends to the inside of the cavity 701. Two limit baffles (704, 710) are arranged in the cavity 701, and a through hole 709 is arranged on the housing 713. To accommodate the extension of the rotating shaft 9 or the insertion of the measured object, the rotating shaft 9 is connected to the measured object to realize linkage. A cylinder 711 is arranged in the cavity 701, and the hole of the cylinder 711 is aligned with the through hole 709. The hole of the cylinder 711 The diameter of the hole is the same as that of the through hole 709. There are two parallel bracket...

Embodiment 2

[0090] It differs from Example 1 in that, as Figure 11 As shown, a notch 712 is provided on the wall of the cylinder 711; Figure 10 As shown, the rotating shaft 9 is provided with a bump 907, and the remaining parts are the same as in Embodiment 1. When installing, the bump 907 is located at the notch 712, so that the cylindrical walls at both ends of the notch 712 along the circumferential direction can limit the bump 907 radians of rotation.

[0091] In addition, the conductive rails in the circuit substrate can be arranged in 1 group, 2 groups, 4 groups or more than 4 groups.

Embodiment 3

[0093] Such as Figure 13 , 14 As shown, it is different from Embodiment 1 in that: the diameter of the hole of the cylinder 711 is the same as that of the through hole 709, the hole of the cylinder 711 is aligned with the through hole 709, a step 908 is set on the rotating shaft 9, and the waterproof ring 708 is sleeved on the rotating shaft 9, the rotating shaft 9 is inserted into the cylinder 711, and the steps 908 are mounted on the wall of the cylinder 711. All the other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com