Torsional vibration excitation device and test bed of vehicle drive system

A vibration excitation device and transmission system technology, which is applied in the field of vehicle transmission system test equipment, can solve problems such as complex structure, high cost, and limitation of excitation frequency, and achieve the effects of strong anti-interference, large adjustment amount, and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described below in conjunction with the accompanying drawings.

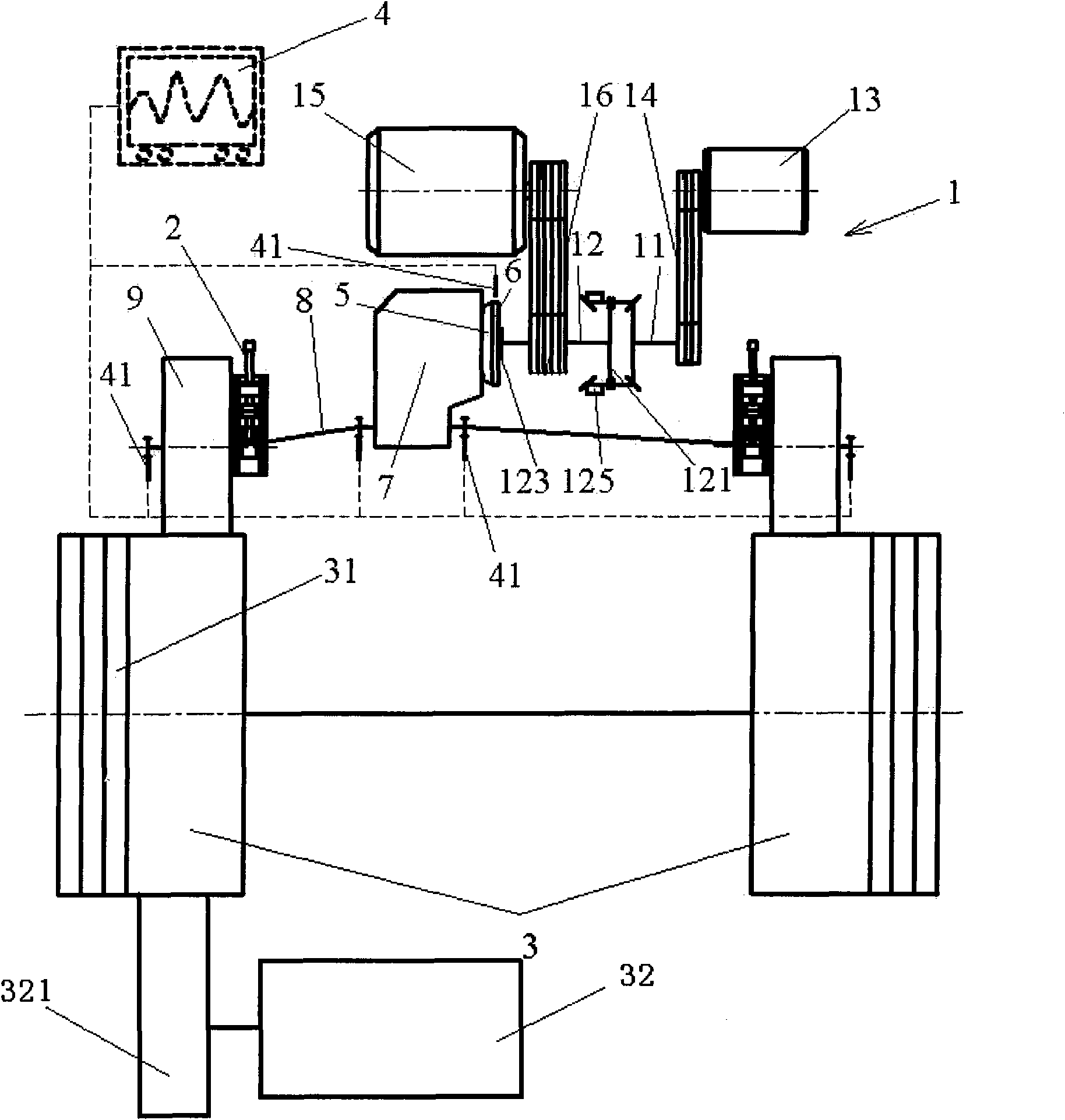

[0032] Such as figure 1 As shown, the test bench of the present invention includes a torsional vibration excitation device 1 , a wheel loading device 2 , an inertia flywheel 3 and a test system 4 . Wherein the torsional vibration excitation device 1 is connected with the flywheel 6 of the transmission system, and the flywheel 6 is connected with the clutch 5 and the transmission differential 7 in turn; the transmission and the differential 7 of the vehicle transmission system are connected with the wheels 9 through the half shaft 8; the wheels 9 It is installed on the loading device 2, and the wheel 9 is pressed against the inertia flywheel 3 by the loading device 2, so that the inertia flywheel 3 is driven by the wheel 9 through friction. The torsional vibration excitation device 1 is used to provide torsional vibration excitation torque with adjustable amplitude and frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com