Method for detecting impurities in nedaplatin

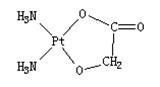

A detection method, nedaplatin technology, applied in the field of inspection of nedaplatin raw material impurities, can solve problems such as no improvement, and achieve the effects of avoiding hidden dangers, stable detection, and prolonging retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Instrument: SHIMADZULC-20AT high performance liquid chromatography;

[0038] Chromatographic column: octylsilane bonded silica gel column (4.6×250mm, 5μm);

[0039] Mobile phase: prepare a water-acetonitrile mixture (volume ratio water: acetonitrile = 70:30), add 0.05% triethylamine in the total volume of the mixture to the water-acetonitrile mixture;

[0040] Column temperature: 40°C;

[0041] Flow rate: 1.0ml / min;

[0042] Detection wavelength: 220nm.

[0043] Preparation of sample solution: Prepare the sample into a solution containing 1 mg / ml of nedaplatin with mobile phase, and store it in the dark at 6°C;

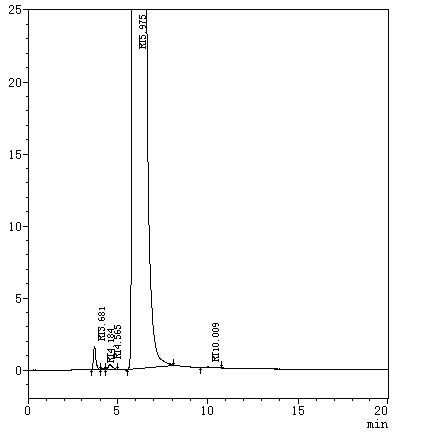

[0044] Determination: Inject 10 μL of sample solution into a high-performance liquid chromatograph, record and analyze the chromatogram, see figure 1 . The test results showed that the impurities were well separated.

Embodiment 2

[0046] Instrument: SHIMADZULC-10AT high performance liquid chromatography;

[0047] Chromatographic column: octylsilane bonded silica gel column (4.6×250mm, 5μm);

[0048] Mobile phase: prepare a mixture with water-acetonitrile (volume ratio 60:40), add 0.005% diethylamine in the total volume of the mixture;

[0049] Column temperature: 20°C;

[0050] Flow rate: 0.5ml / min;

[0051] Detection wavelength: 215nm.

[0052] Preparation of sample solution: use mobile phase to prepare the sample into a solution containing 0.5 mg / ml of nedaplatin, and store it in the dark at 8°C;

[0053] Determination: Inject 20 μL of the sample solution into a high-performance liquid chromatograph, record and analyze the chromatogram, and the test results show that the impurities are well separated.

Embodiment 3

[0055] Instrument: SHIMADZULC-20AT high performance liquid chromatography;

[0056] Chromatographic column: octylsilane bonded silica gel column (4.6×250mm, 5μm);

[0057] Mobile phase: prepare a mixture with water-methanol (volume ratio 80:20), add 0.1% triethylamine of the total volume of the mixture to the mixture;

[0058] Column temperature: 45°C;

[0059] Flow rate: 1.2ml / min;

[0060] Detection wavelength: 210nm.

[0061] Preparation of sample solution: use mobile phase to prepare the sample into a solution containing 2 mg / ml of nedaplatin, and store it in the dark at 2°C;

[0062] Determination: Inject 5 μL of the sample solution into a high-performance liquid chromatograph, record the chromatogram and analyze it. The test results show that the impurities are well separated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com