Spherical thin-film solar cell, preparation method thereof and spatial arrangement assembly based on cell

A technology of thin-film solar cells and thin-film batteries, which can be applied to circuits, photovoltaic power generation, electrical components, etc., and can solve problems such as inability to absorb sunlight to the maximum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Structural design of solar cells

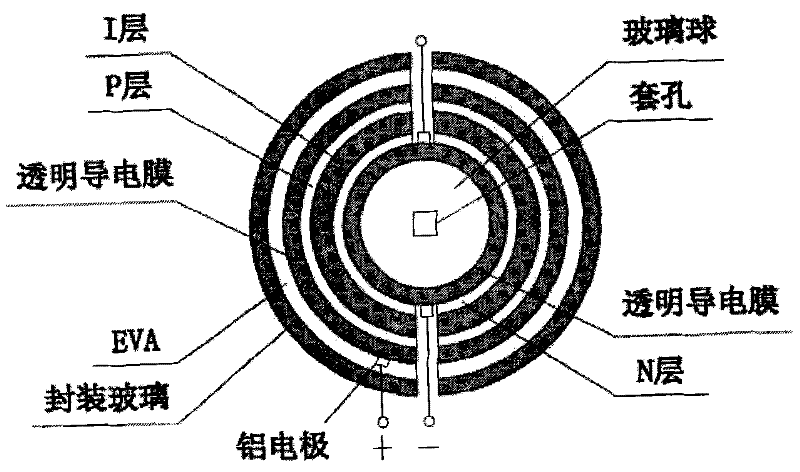

[0045] The diameter of the glass sphere is 10cm, and a 50nm-thick ITO film is sequentially grown on the glass sphere, hydrogenated nano-silicon NIP structure (N, I, P layer thicknesses are 10, 400, 10nm, respectively), and a 70nm-thick Al x Zn 1-x O(x=0.02) thin film, lead out aluminum electrodes, and finally use EVA and two hemispherical glass for encapsulation. (Such as figure 1 shown)

[0046] 2. Preparation of solar cells

[0047] 2.1 Cleaning of glass balls

[0048] The glass spheres were ultrasonically cleaned with acetone, rinsed with deionized water, and dried.

[0049] 2.2 Preparation of transparent bottom electrode by sputtering method

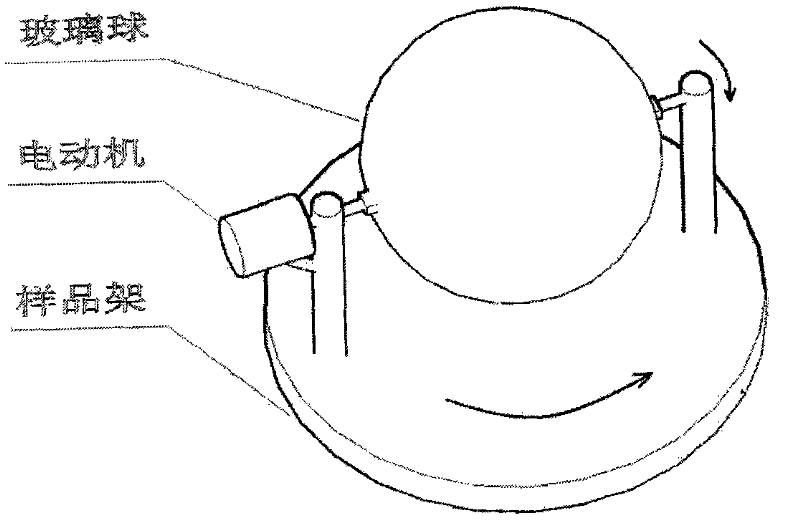

[0050] The background vacuum of the sputtering chamber is 1×10 -4 Pa, use the sputtering method to sputter the ITO ceramic target on the cleaned glass ball, and deposit the ITO film with a thickness of about 50nm. Glass spheres are mounted on a three-dimensional sample stage (such ...

Embodiment 2

[0066] Structural Design of Solar Cells

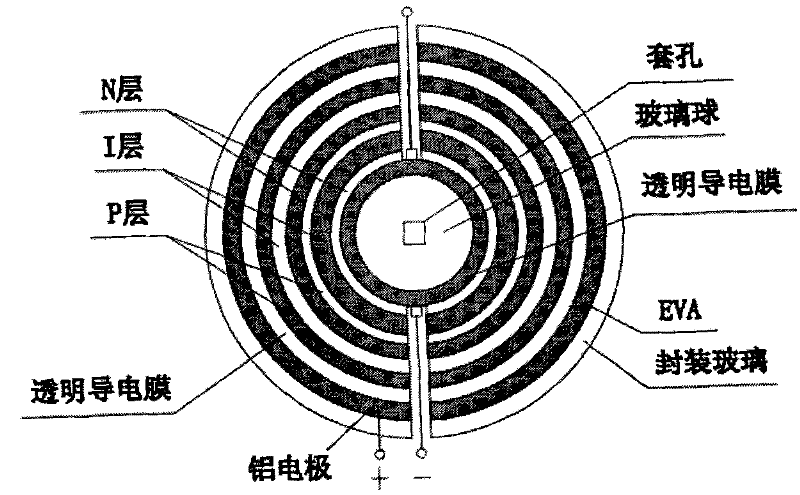

[0067] The diameter of the glass sphere is 10cm, and the ITO film with a thickness of 50nm is grown successively on the glass sphere, and the amorphous silicon / microcrystalline silicon laminated battery (the N, I, and P layer thicknesses of the microcrystalline silicon bottom battery are 10, 1000, 10nm respectively, The thickness of the N, I, and P layers of the amorphous silicon top cell is 10, 200, and 10nm respectively), and the 70nm thick Al x Zn 1-x O(x=0.02) thin film, lead out aluminum electrodes, and finally use EVA and two hemispherical glass for encapsulation. (Such as figure 2 )

[0068] The difference from Embodiment 1 is that the thin film battery adopts the laminated structure of amorphous silicon / microcrystalline silicon film and uses the PECVD method to prepare hydrogenated amorphous silicon / microcrystalline silicon laminated battery on the bottom electrode.

[0069] Glass spheres are mounted on a three-dimensional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com