Line heat source

A wire heat source and a wire-line technology, applied in the field of wire heat sources based on carbon nanotubes, can solve the problems of being easily damaged, the quality of the heating wire is large, unfavorable to the micro heat source, etc., and achieve the effects of not being easily damaged, and having high mechanical strength and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

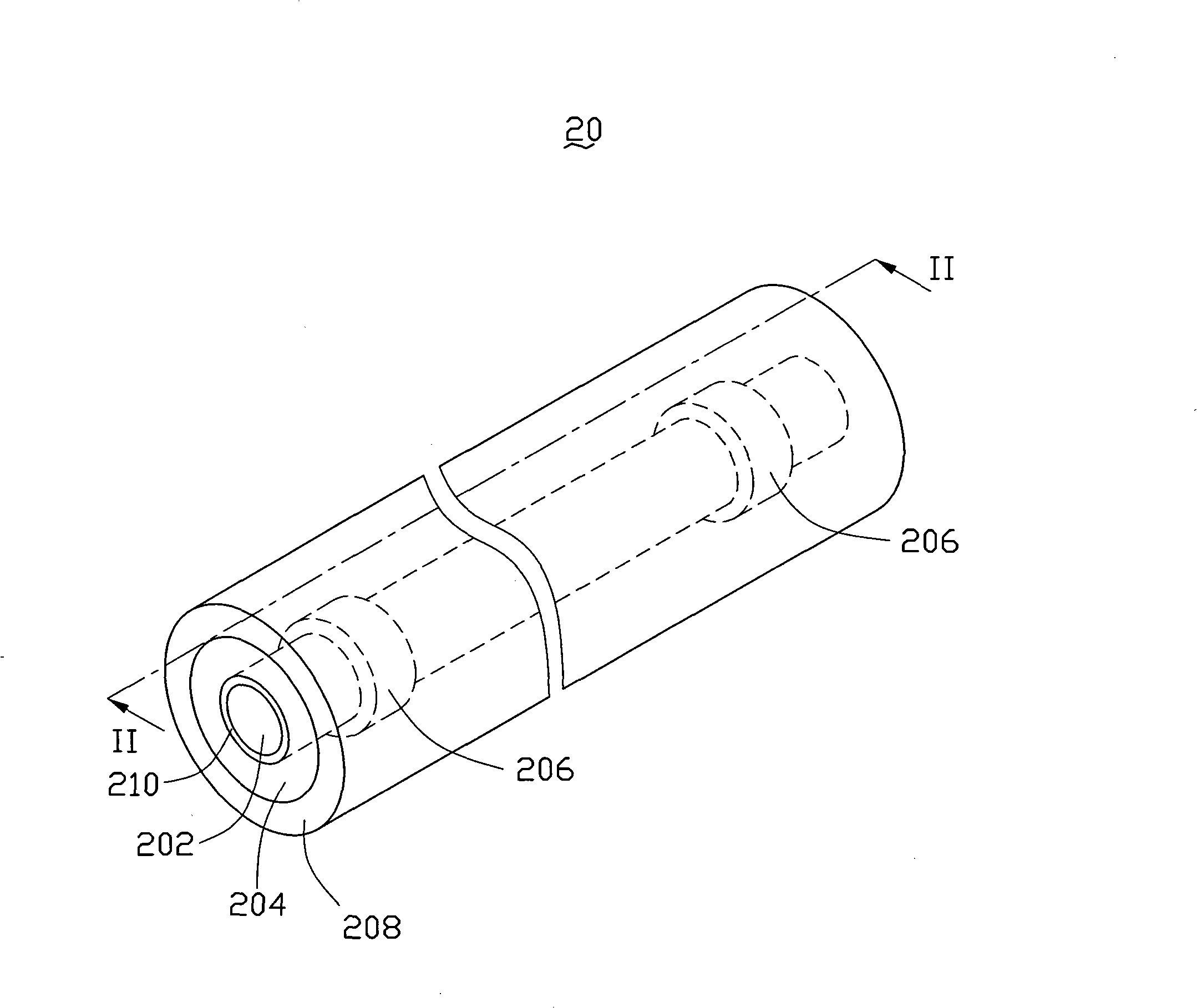

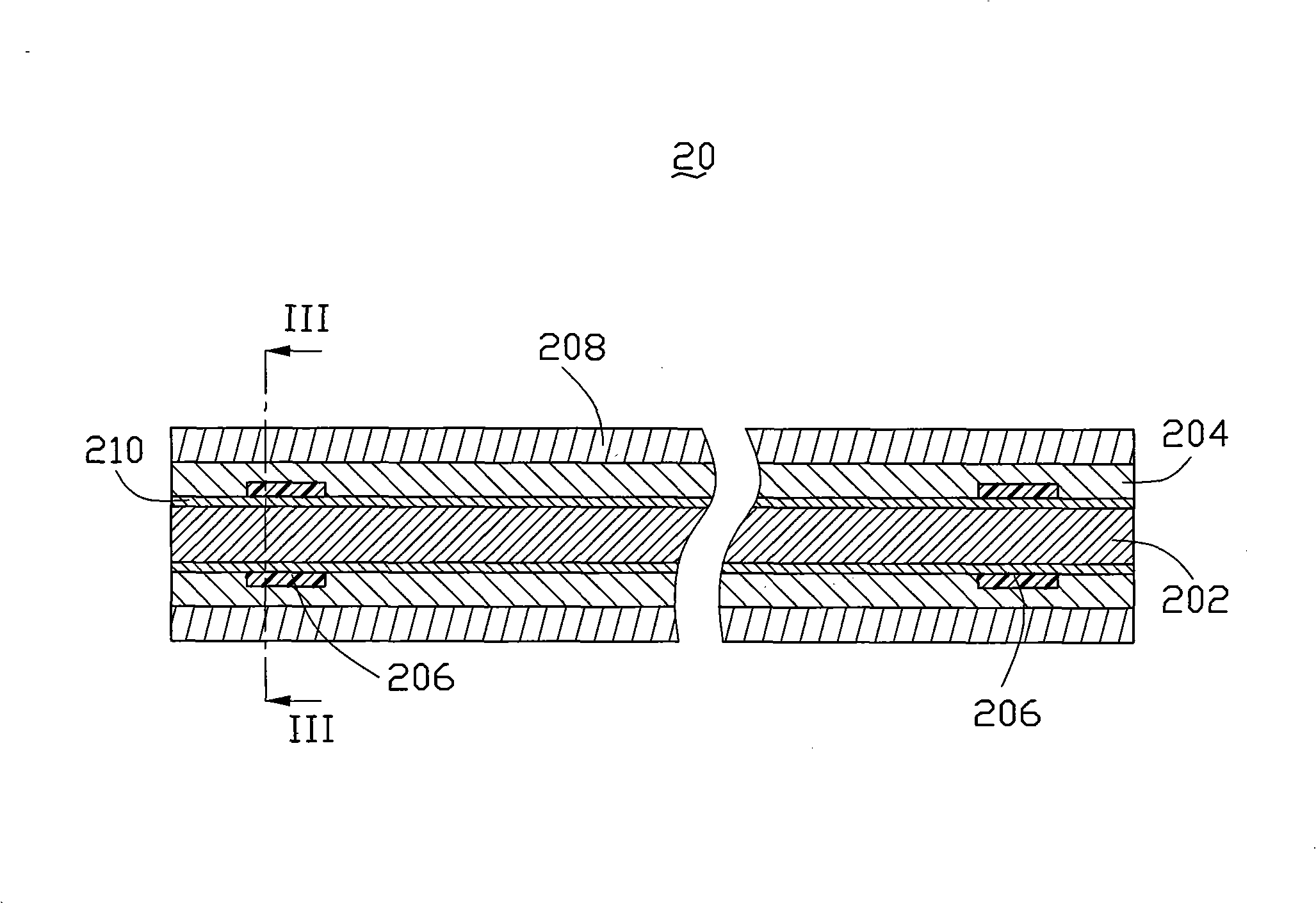

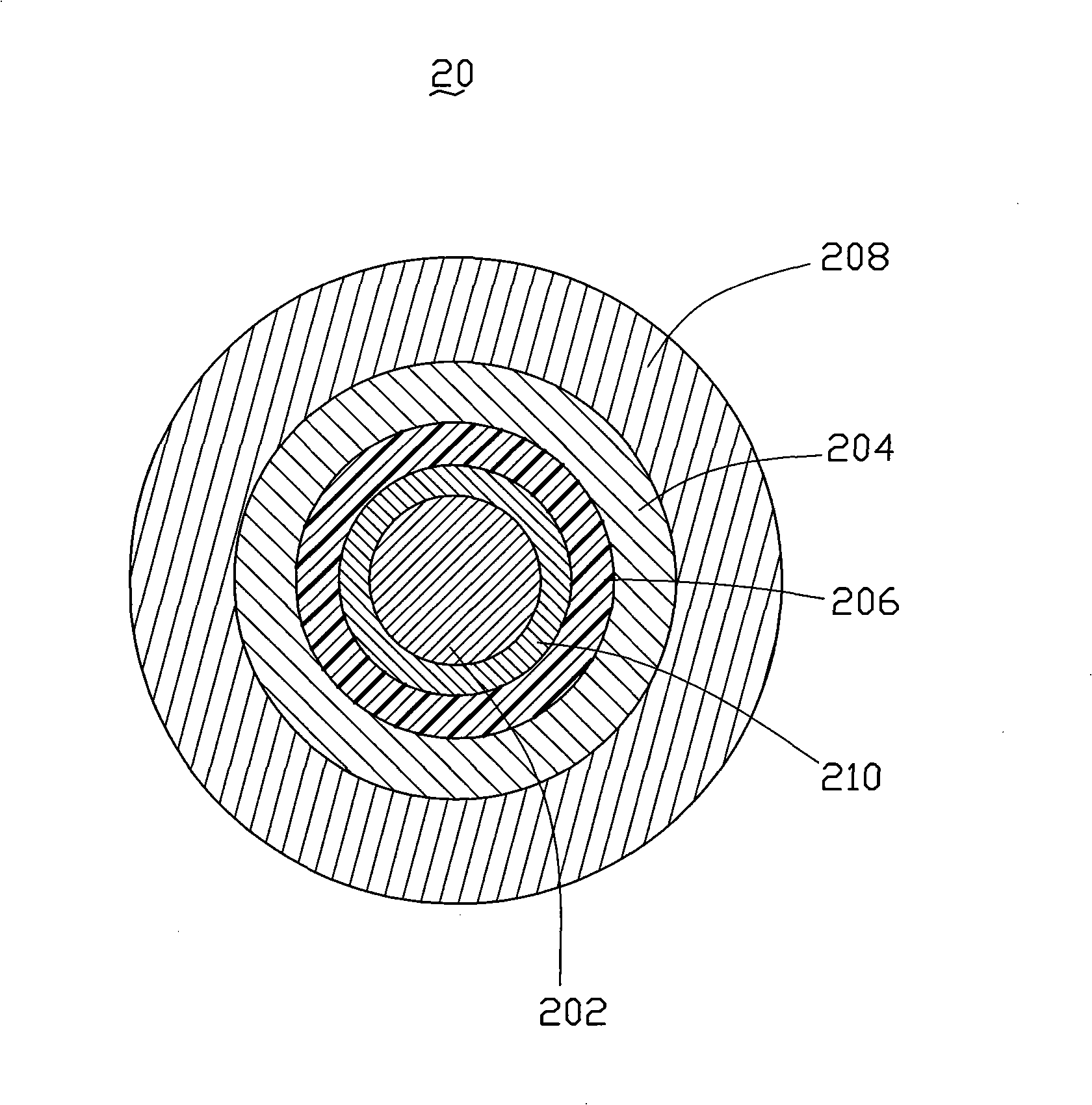

[0071] See Figure 16 , The first embodiment of the present invention further provides a method for preparing the linear heat source 20, which specifically includes the following steps:

[0072] Step S101, providing a carbon nanotube structure.

[0073] According to the difference of the carbon nanotube structure, the preparation method of the carbon nanotube structure includes: direct film drawing method, rolling method, flocculation method and the like. The preparation methods of the above-mentioned carbon nanotube structures will be separately described below.

[0074] (1) When the carbon nanotube structure includes at least one drawn carbon nanotube film, the method for preparing the carbon nanotube structure includes the following steps:

[0075] First, a carbon nanotube array is provided on a growth substrate, and the array is preferably a super-in-line carbon nanotube array.

[0076] The preparation method of the carbon nanotube array adopts the chemical vapor deposition method,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com