Double-workbench drive laser processing machine and processing method thereof

A laser processing machine and dual-table technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low processing efficiency, poor automatic visual alignment accuracy, and insufficient flexibility of mechanical punching machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The preferred specific embodiments described here are only used to explain the present invention, and are not suitable for limiting the present invention.

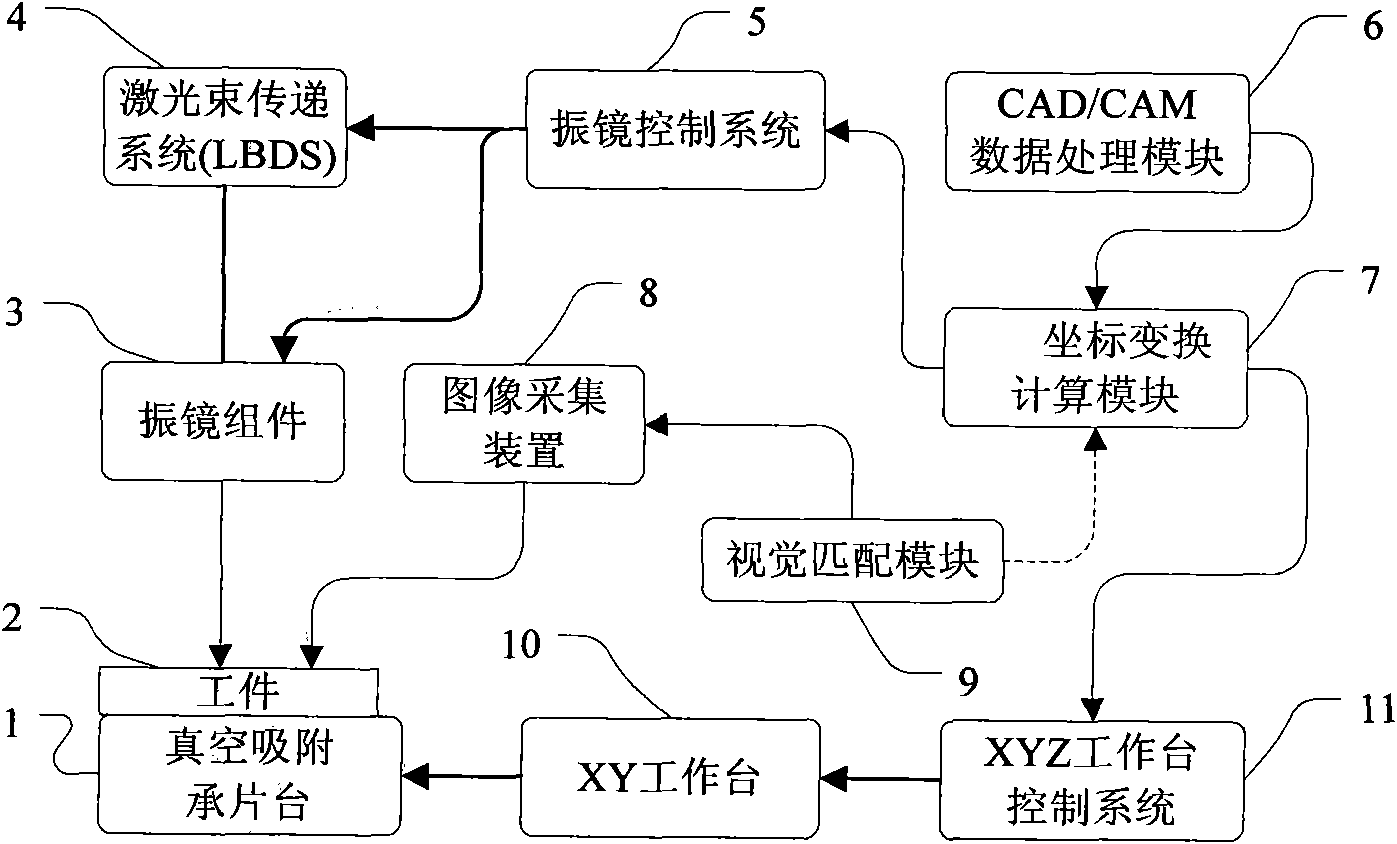

[0063] In this preferred embodiment, if image 3 As shown, the laser processing machine system includes:

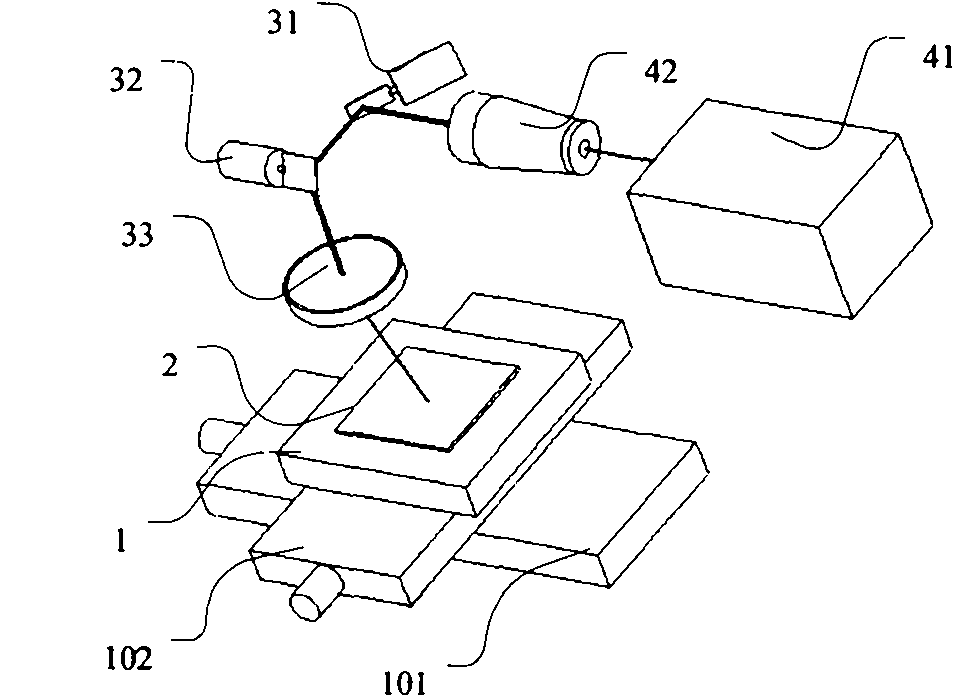

[0064] The first workbench, that is, the two-dimensional scanning galvanometer assembly 3, such as Figure 6 As shown, it consists of a first reflector 31 , a second reflector 32 , a telecentric f-θ lens 33 and a support frame 34 . Through the vibrating mirror control system 5, the laser marking process on the workpiece 2 is realized.

[0065] The second workbench is the XYZ workbench device. Such as Figure 4 As shown, the second workbench is composed of an XY workbench 10 and a Z-direction workbench 103 . Through the XYZ workbench control system 11, the movement and positioning of the vacuum suction substrate 1 (on which the workpiece 2 is adsorbed) in the horizontal plane and Z-direction laser focusing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com