Waste removal all-in-one machine for die cutting paper product

An all-in-one machine and paper product technology, applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve problems such as low work efficiency, high labor intensity of workers, and unstable quality, so as to improve production efficiency and improve positioning accuracy performance, reliability, and service life guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

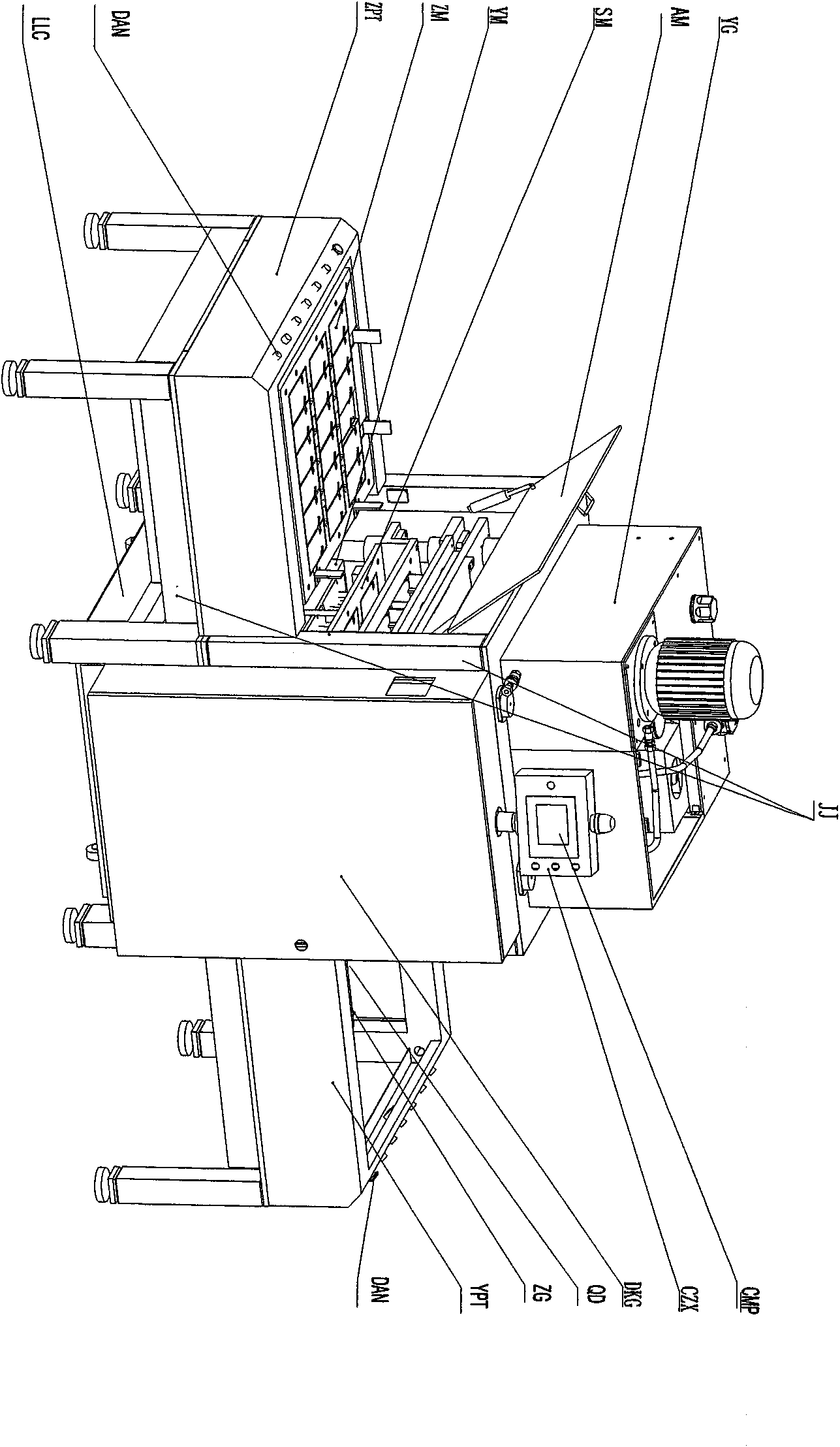

[0033] See figure 1 , figure 2 , image 3 , a die-cutting paper waste separation machine, including a frame (JJ), an electric control cabinet (DKG), an upper mold and a corresponding lower mold; the upper mold is equipped with a hydraulic system (YG). The knife plate from the upper mold is used to remove the waste edge of the die-cut paper, and the punching plate that can be extended to remove the excess waste in the middle of the die-cut paper manipulated by the hydraulic system device; Unclog the air duct for punching out the excess waste in the middle of the punching plate, and the supporting plate for receiving the waste edge of die-cut paper that can be misplaced with the lower die operated by the power device; the hydraulic system (YG) is controlled by the electric control cabinet (DKG) control.

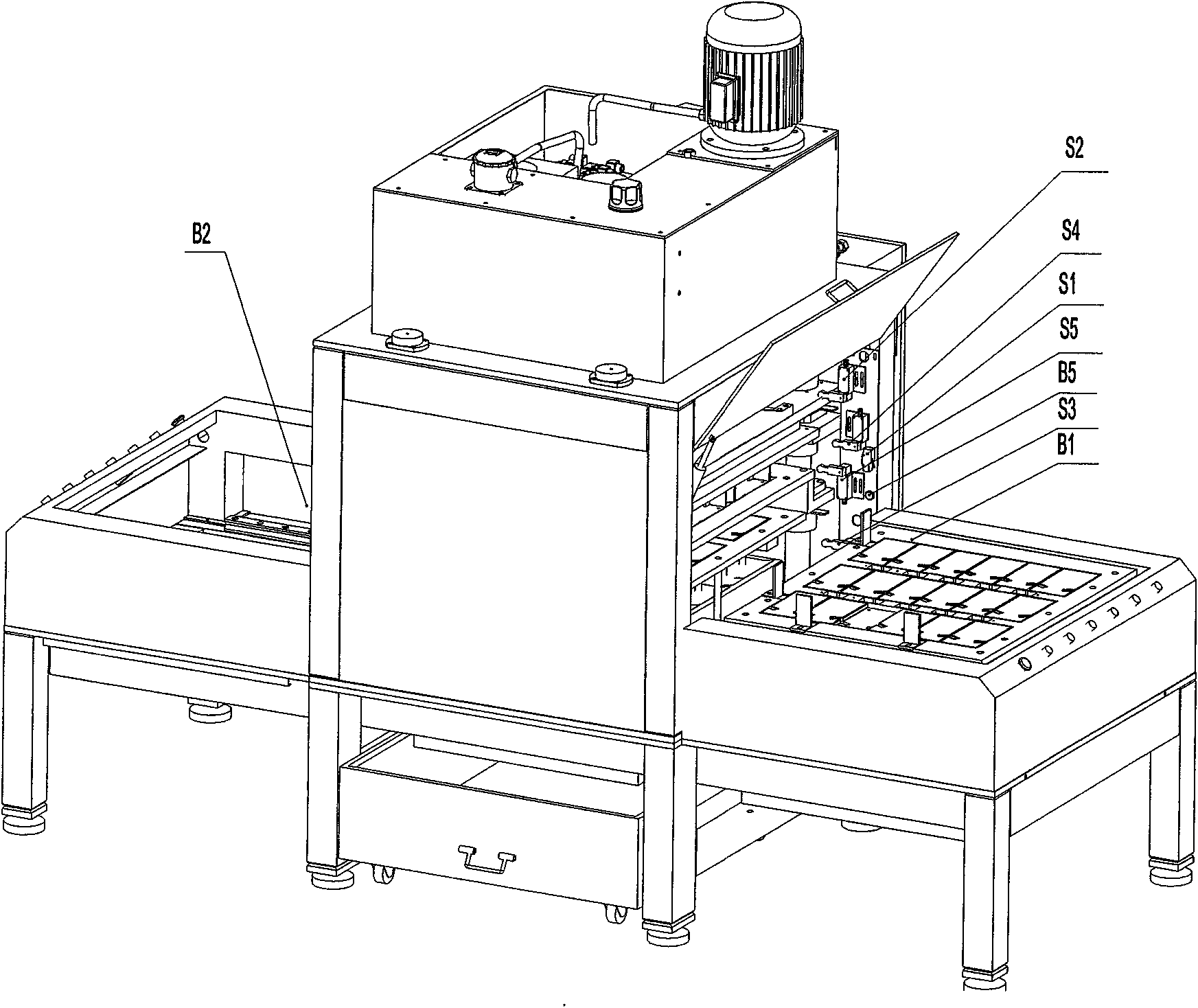

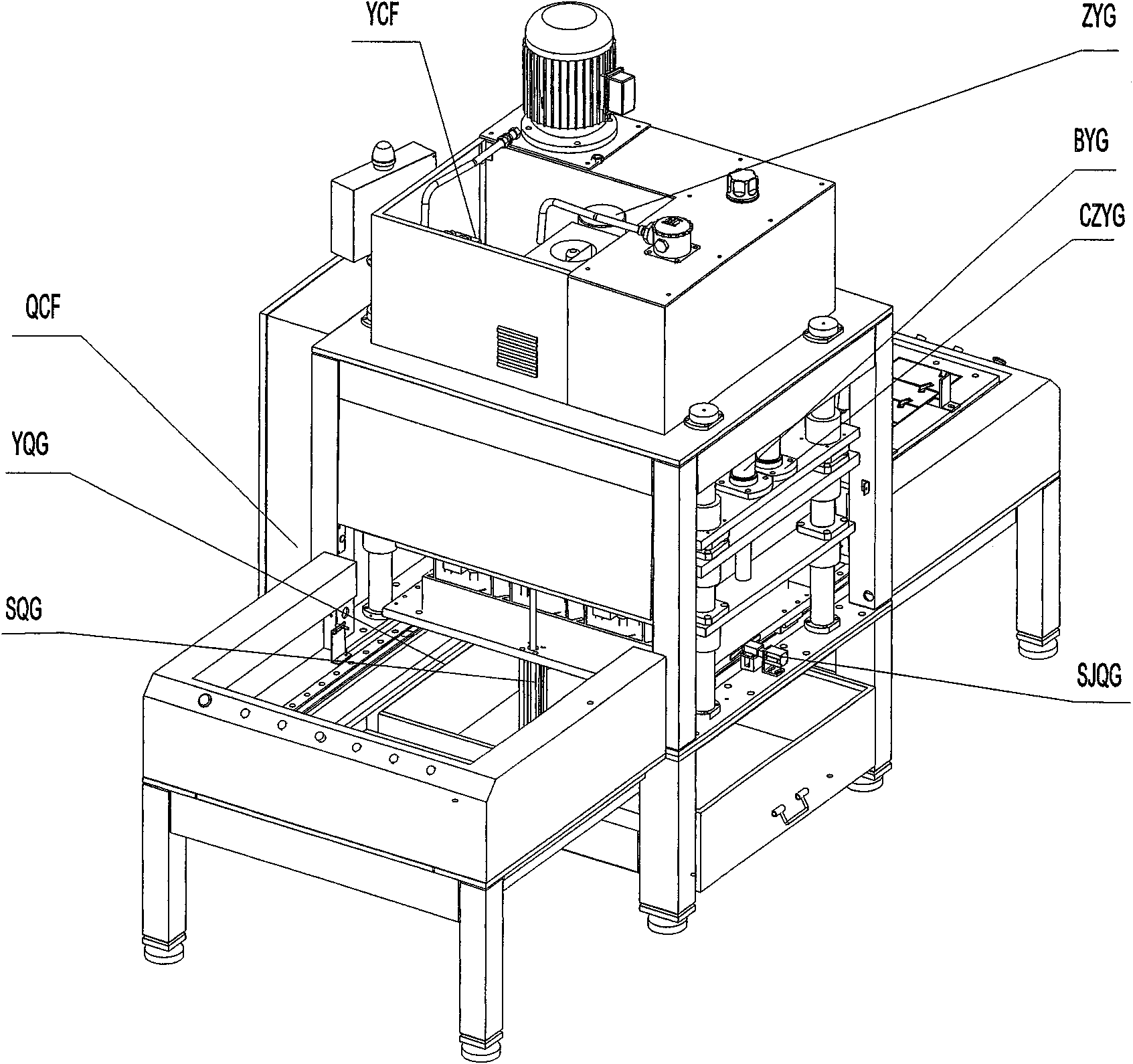

[0034] See Figure 4 , Figure 5 , the lower mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com