Ca/Mg/Zn composite stabilizer for polyvinyl chloride and preparation method thereof

A composite stabilizer, polyvinyl chloride technology, applied in the field of plastic processing, to achieve the effect of bright surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

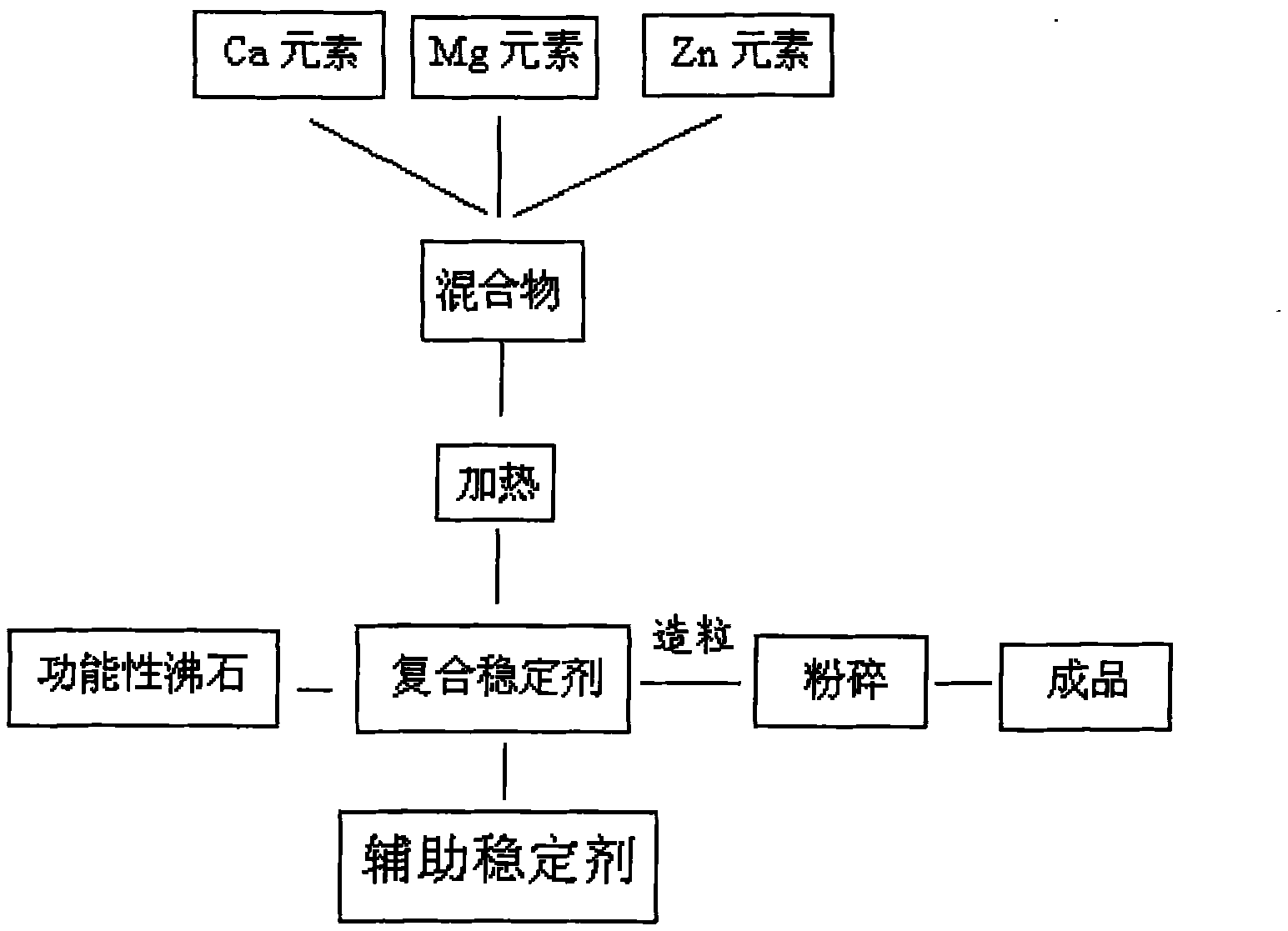

[0028] according to figure 1 The preparation method of Ca / Mg / Zn composite stabilizer stabilizer for polyvinyl chloride is to mix 5 parts of elemental Ca, 10 parts of elemental Mg, and 20 parts of elemental Zn, and heat the mixture to 180°C to melt the mixture to form a Ca / Zn complex and Mg / Zn complex, then add 10 parts of functional zeolite and auxiliary stabilizer, mix well, extrude and granulate with a twin-screw extruder, and then pulverize the granules to obtain powder.

Embodiment 2

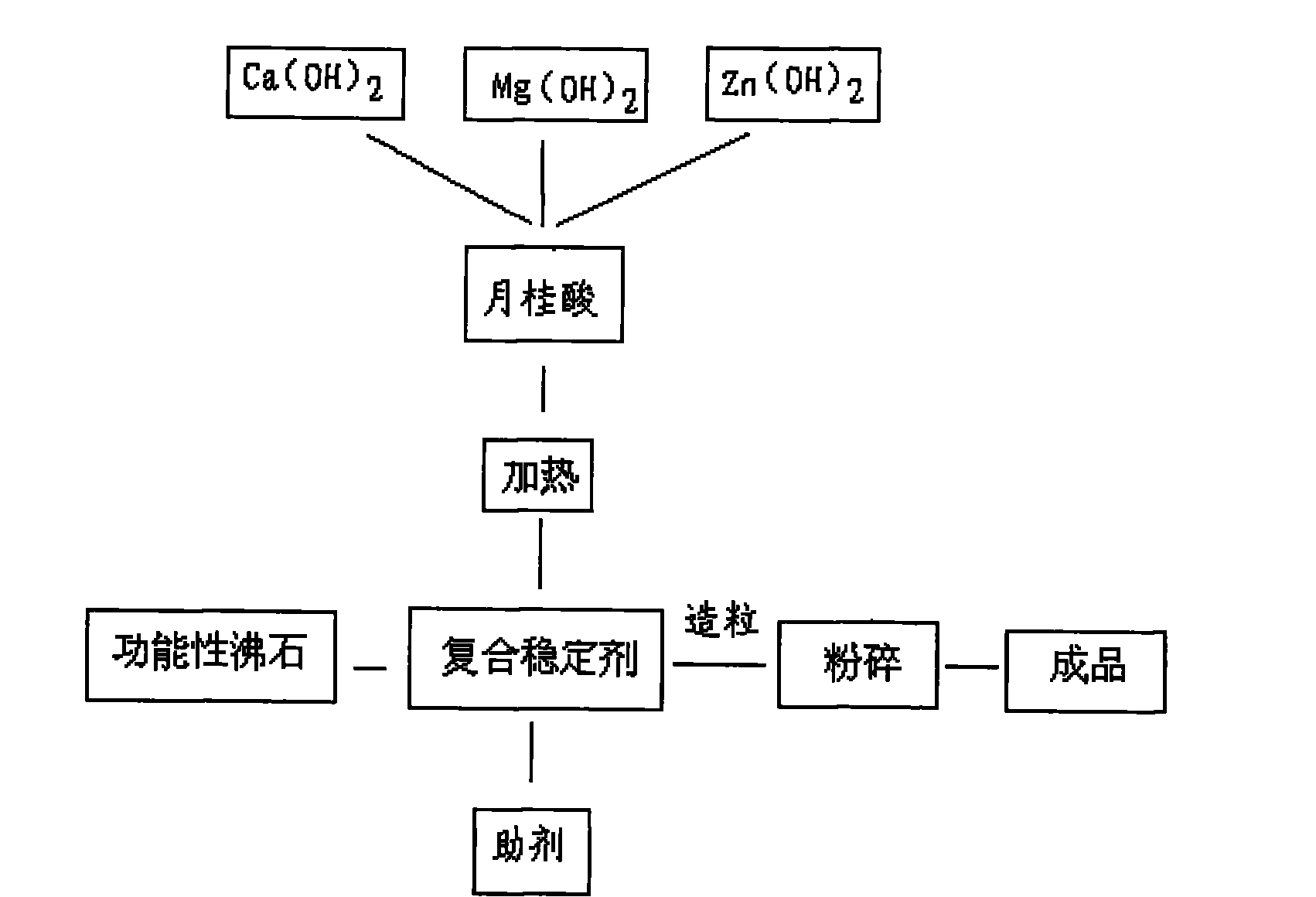

[0030] according to figure 1 Preparation method of Ca / Mg / Zn composite stabilizer stabilizer for polyvinyl chloride, 5 parts of calcium stearate, 10 parts of zinc laurate, 5 parts of hydrotalcite, mix well, heat the mixture to 160 ° C to melt the mixture to form Ca / Zn complex and Mg / Zn complex are added with 10 parts of functional zeolite and auxiliary stabilizer, mixed evenly, extruded and granulated with a twin-screw extruder, and then pulverized to obtain powder.

Embodiment 3

[0032] according to figure 1 Preparation method of Ca / Mg / Zn composite stabilizer stabilizer for polyvinyl chloride, 5 parts of calcium stearate, 10 parts of zinc laurate, 5 parts of magnesium carbonate, mix well, heat the mixture to 160 ° C to melt the mixture to form Ca / Zn complex and Mg / Zn complex are added with 10 parts of functional zeolite and auxiliary stabilizer, mixed evenly, extruded and granulated with a twin-screw extruder, and then pulverized to obtain powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com