Drilling fluid PLC automatic control system and control method thereof

A technology of automatic control system and control method, which is applied in sequence/logic controller program control, electrical program control, construction, etc., can solve the problems of manual preparation of drilling fluid, avoid engineering quality accidents, and monitor technical parameters in real time , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0013] Five, specific embodiment: the present invention will be further described below in conjunction with accompanying drawing:

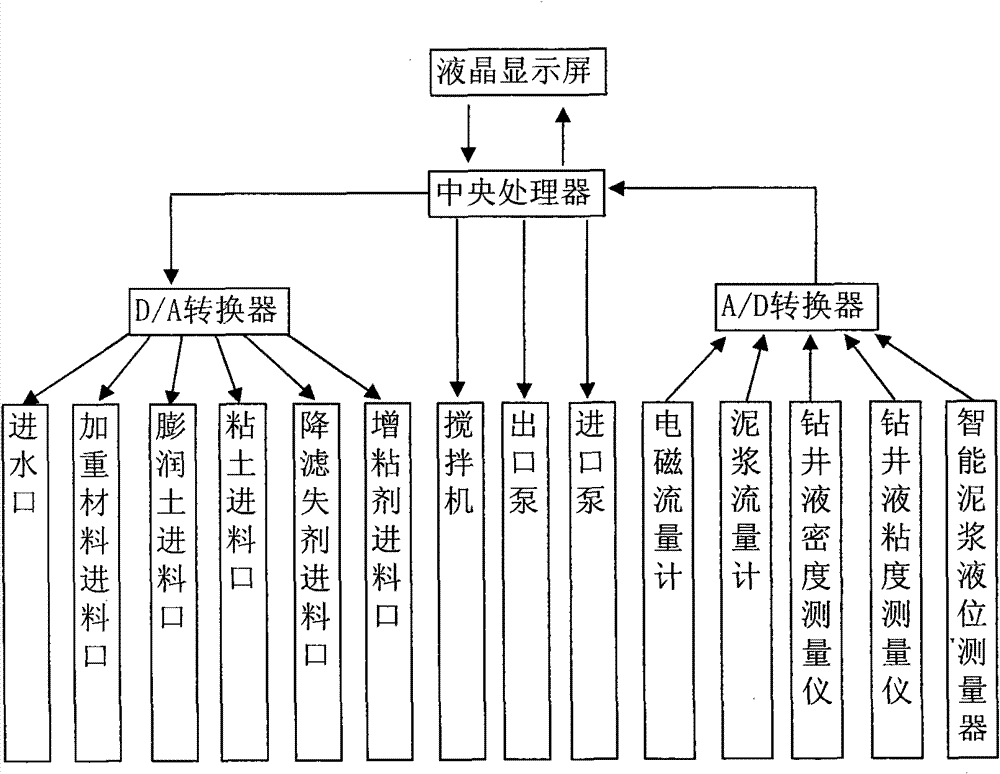

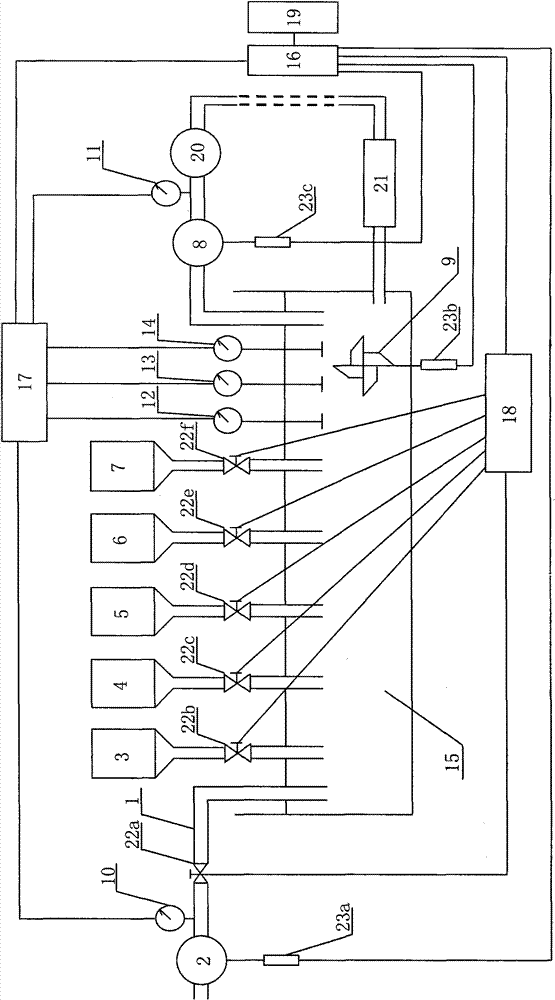

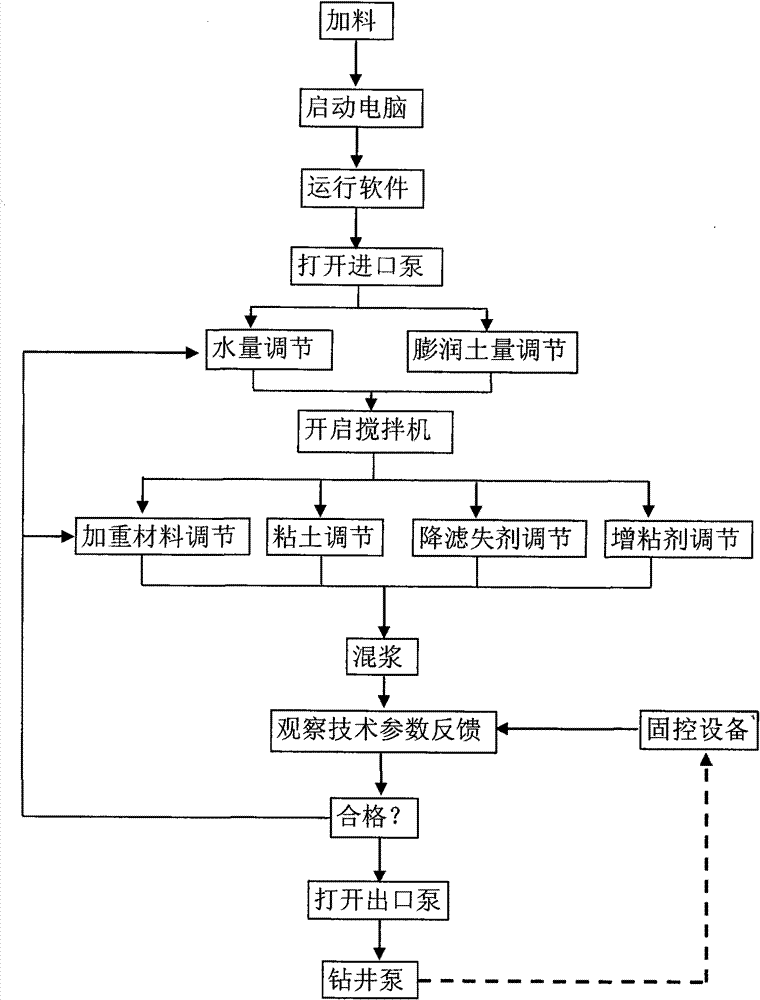

[0014] figure 1 It is the working block diagram of the PLC automatic control system in the present invention, figure 2 It is a schematic structural diagram of the automatic control system in the present invention, and the dotted line part in the figure represents the drilling cycle, combined with figure 1 , figure 2 As shown, the drilling fluid PLC automatic control system is used in conjunction with the drilling pump 20 and the solid control equipment 21. The system is composed of a central processing unit 16, an A / D converter 17, a D / A converter 18, and a liquid crystal display 19. The central processing unit, and the electromagnetic flowmeter 10, mud flowmeter 11, intelligent mud level measuring device 12, drilling fluid density tester 13, drilling fluid viscosity measuring instrument 14, mixer 9, clay feeding port 3, Bentonite inlet 4, we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com