Infrasonic wave detection device and method

A detection device and detection method technology, applied in the direction of measuring device, measuring ultrasonic/sonic wave/infrasonic wave, using wave/particle radiation, etc., can solve the problems of sensor zero drift, high market price, etc., and achieve low processing accuracy requirements and overall structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

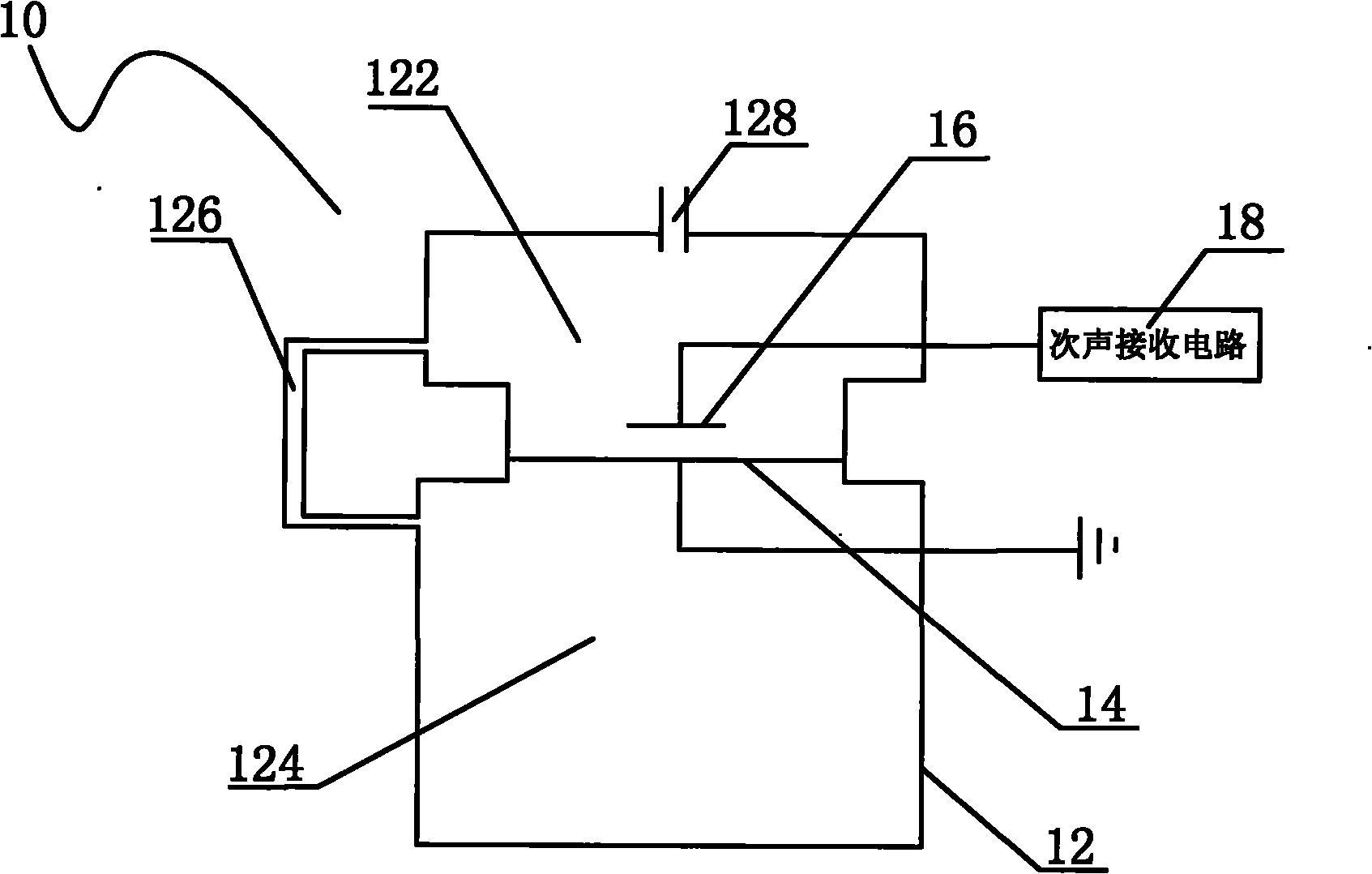

[0023] see Figure 4 , which is a front view of the infrasonic wave detection device of the present invention. The infrasonic wave detection device 100 includes a laser 110, a beam expander 120, a diaphragm single-slit device 130, a polarizer 140, and a CCD (charge-coupled device) light receiving system 150 arranged on a straight line in sequence. It also includes a single-chip microcomputer and a display screen (not shown).

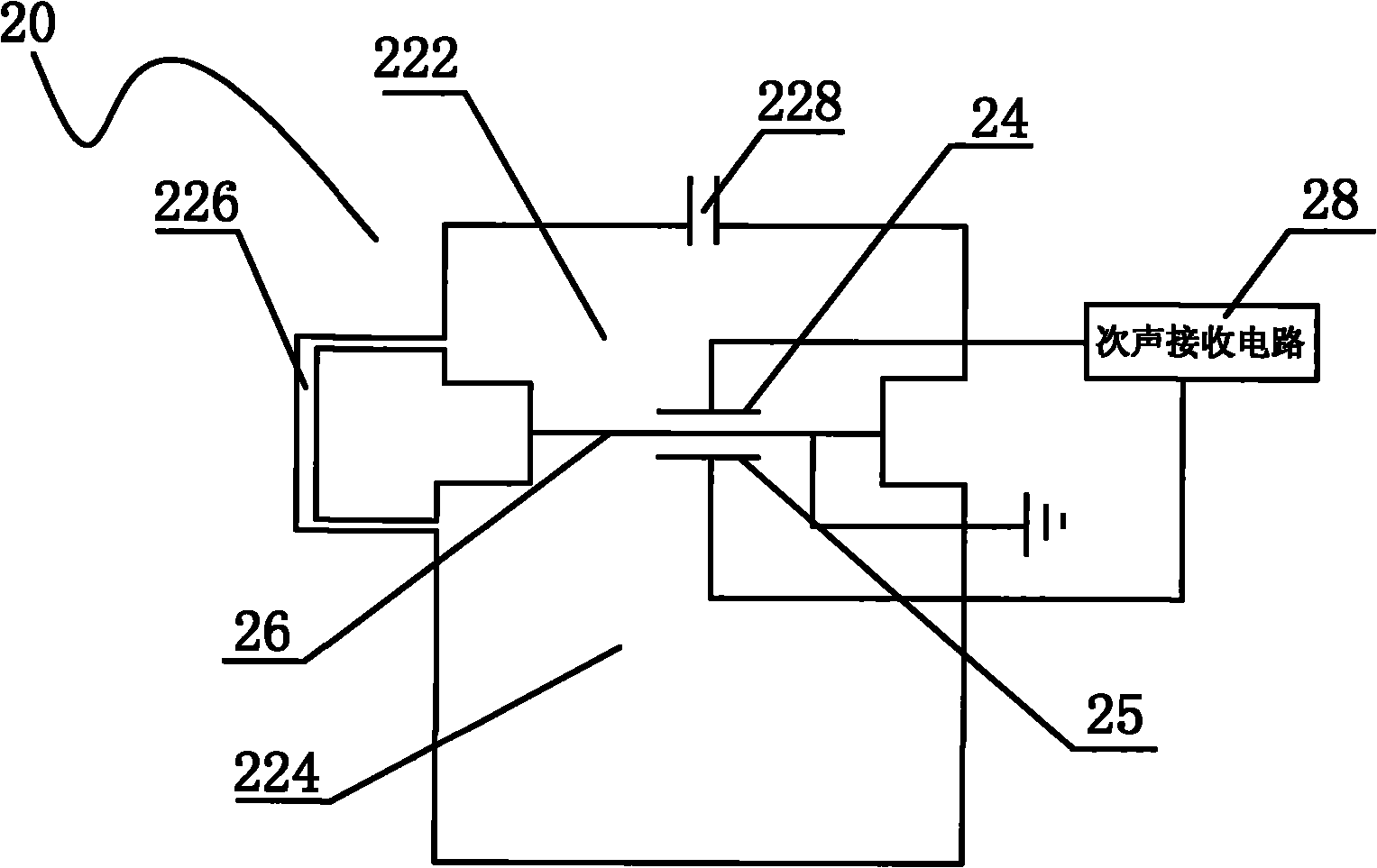

[0024] Please also see Figure 5 ,actually Figure 4 The top view of the infrasonic detection device shown. The diaphragm single-slit device 130 includes a first blade 132 a , a second blade 132 b and a sensitive diaphragm 134 . The first blade 132a and the second blade 132b are arranged on a plane perpendicular to the optical axis of the laser, and are separated to form a single slit A through which the laser passes. The sensitive diaphragm 134 is arranged on a plane parallel to the laser optical axis and the single slit A, and is in vertical conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com