Thermoelectric power generator and power generating system using thermoelectric power generator

A technology for thermoelectric power generation and power generation system, which is applied to generators/motors, steam engine installations, ocean energy power generation, etc. It can solve the problems of no heat energy recovery, unavoidable cost increase, and complex overall structure, so as to avoid cost increase, Easy maintenance and small space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

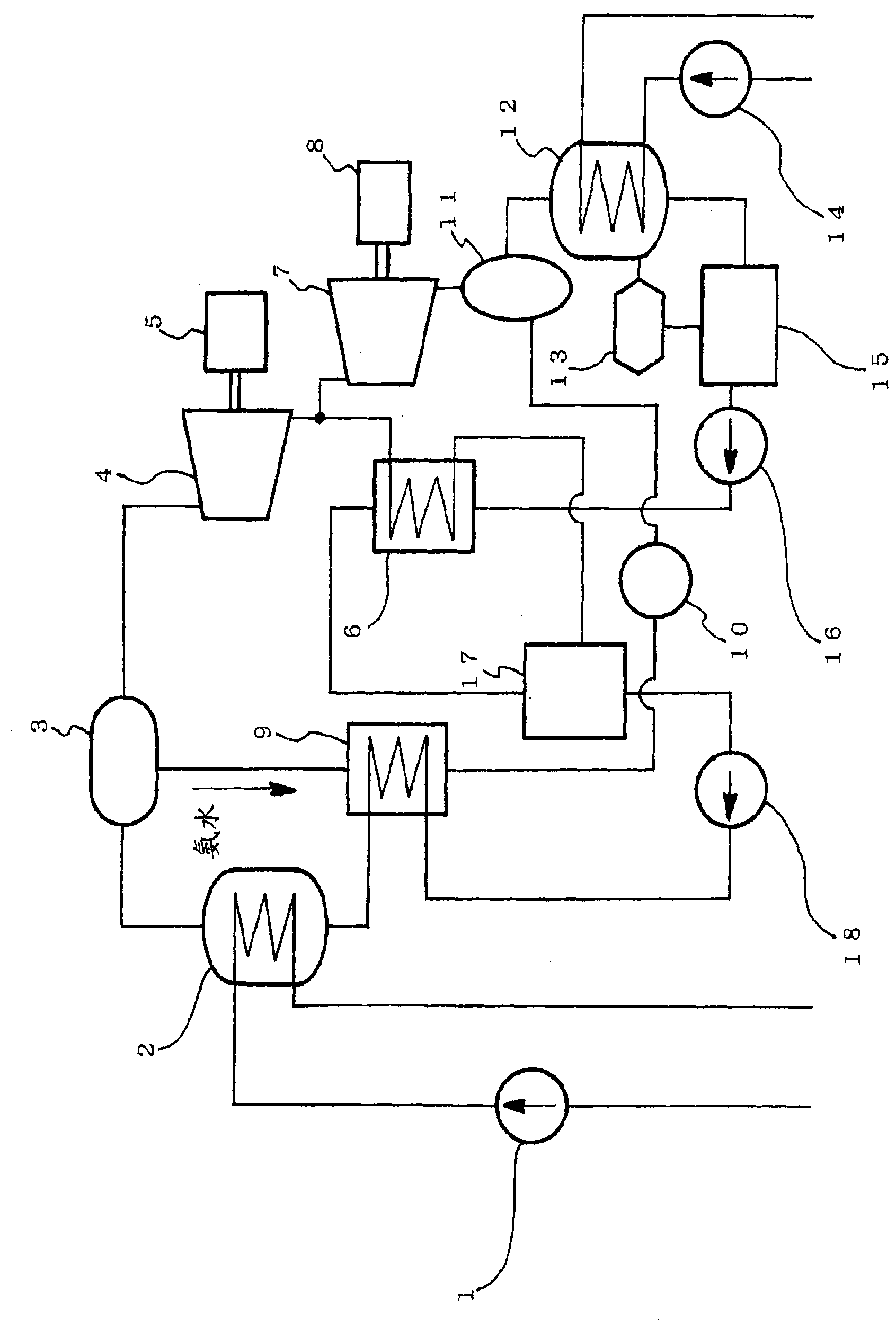

[0062] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

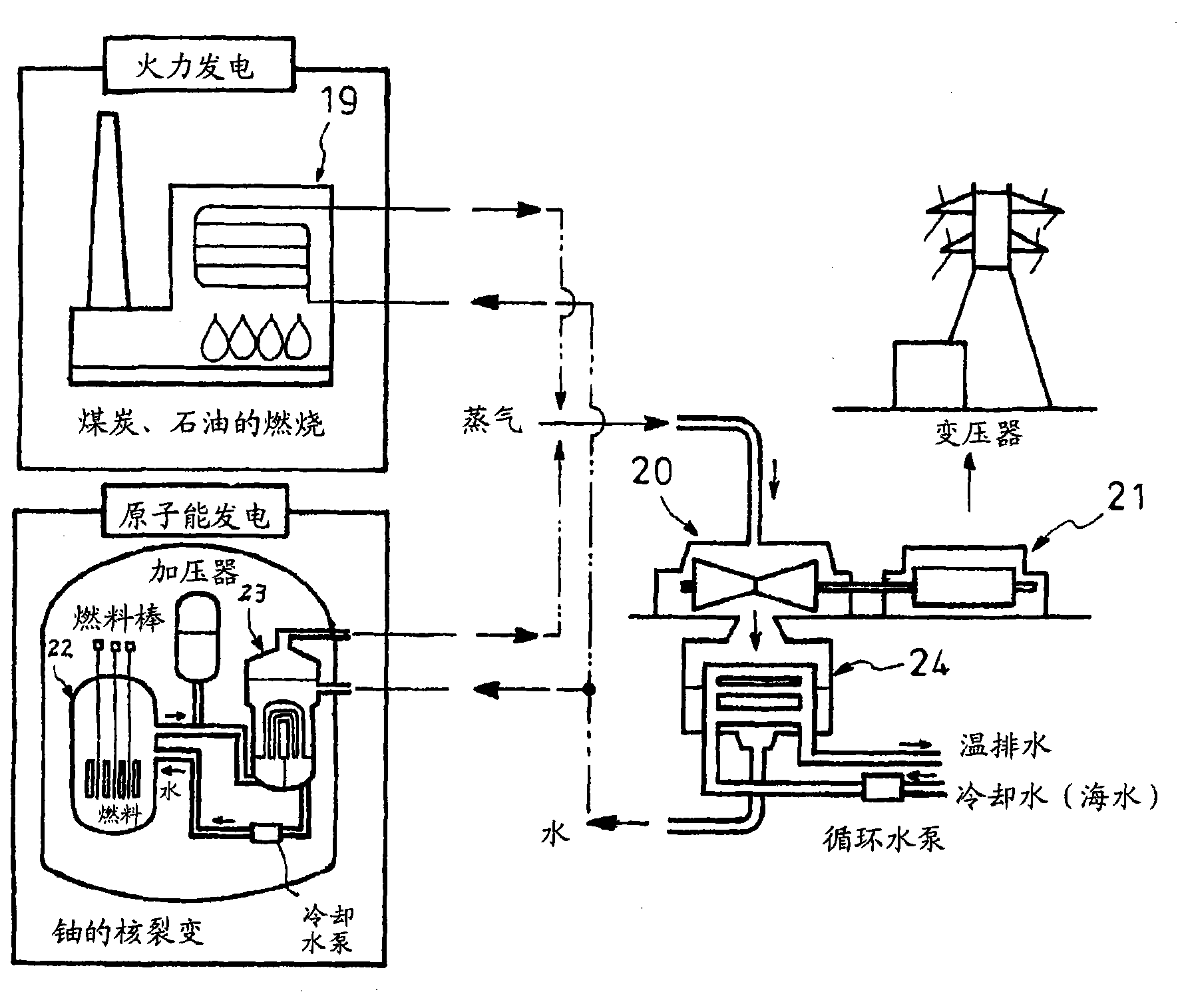

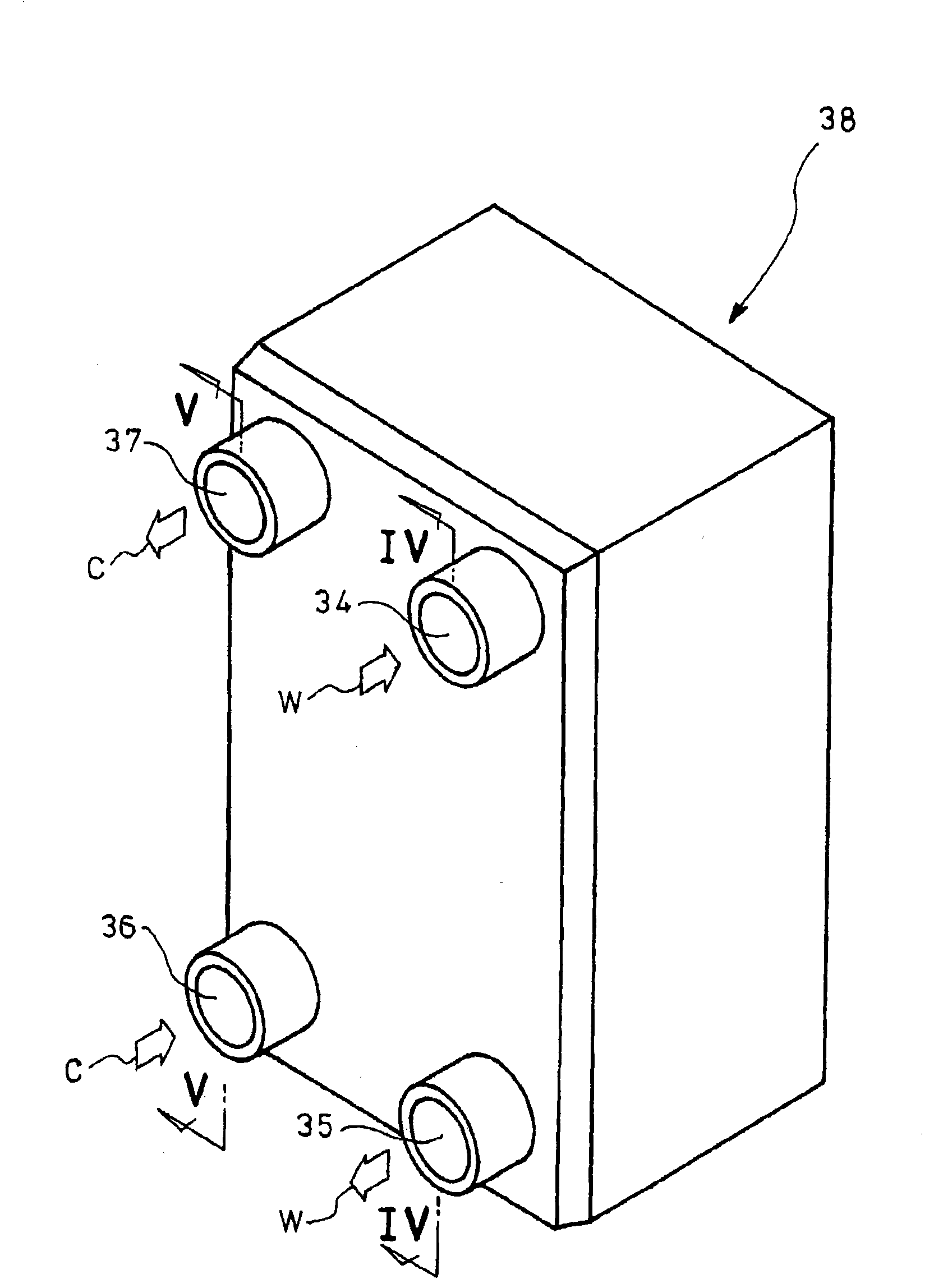

[0063] Figure 3 ~ Figure 8 It is an embodiment of the present invention, wherein the thermoelectric elements 27 with P-type thermoelectric semiconductor elements 25 and N-type thermoelectric semiconductor elements 26 alternately arranged side by side are enclosed in the heat transfer plate 30 in a manner sandwiched by electrodes 28 and insulators 29 In order to form a plate-shaped thermoelectric generating unit 31, a plurality of plate-shaped thermoelectric generating units 31 are stacked, and high-temperature fluids are alternately formed between the plate-shaped thermoelectric generating units 31 with each of the above-mentioned plate-shaped thermoelectric generating units 31 as a boundary. The first space 32 through which W flows and the second space 33 through which the low-temperature fluid C flows are formed by connecting the openings formed in the above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com