Draught beer barrel cleaner

A cleaning machine and beer keg technology, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemistry, etc., to achieve the effect of improving cleaning efficiency and per capita efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

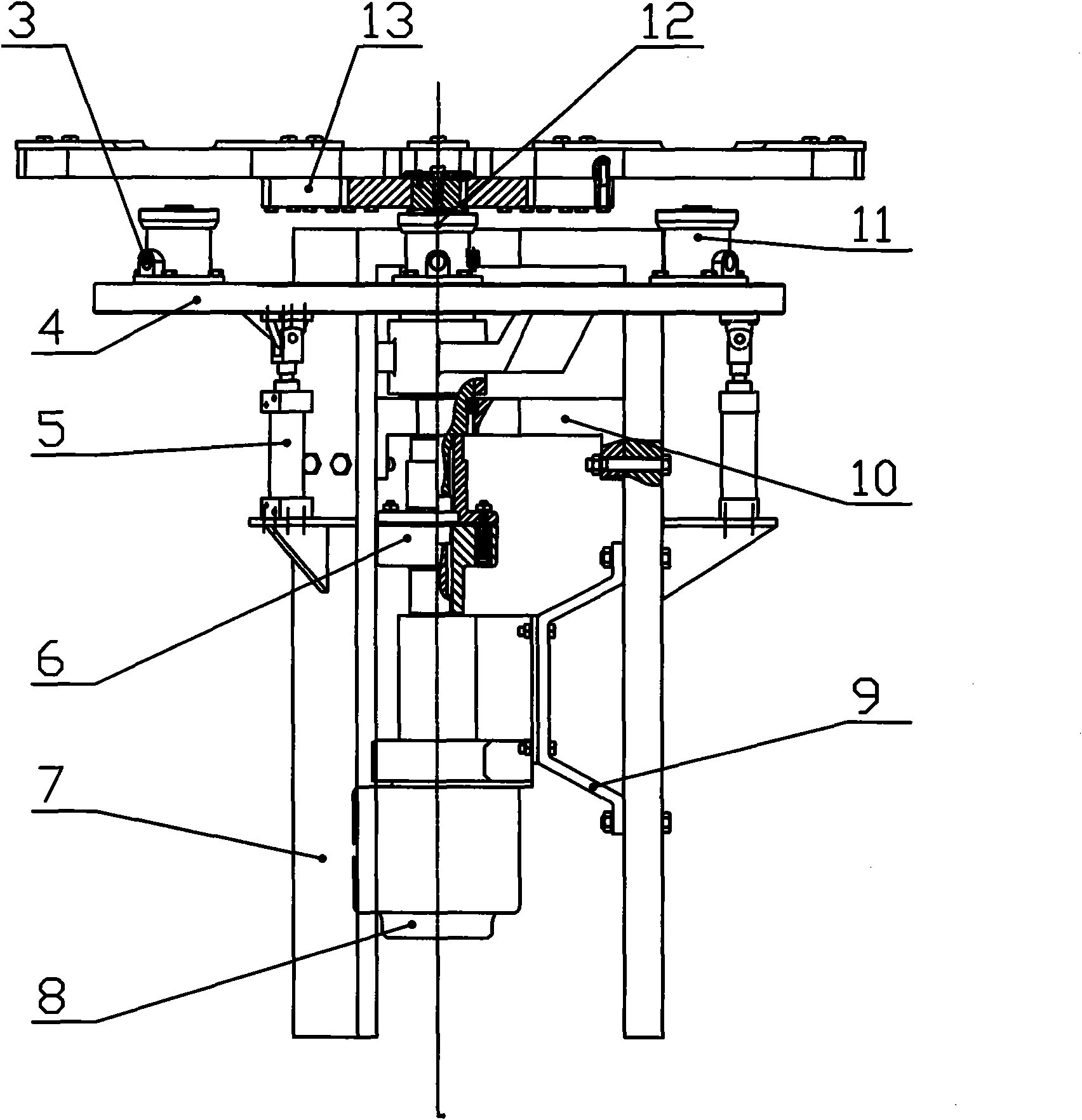

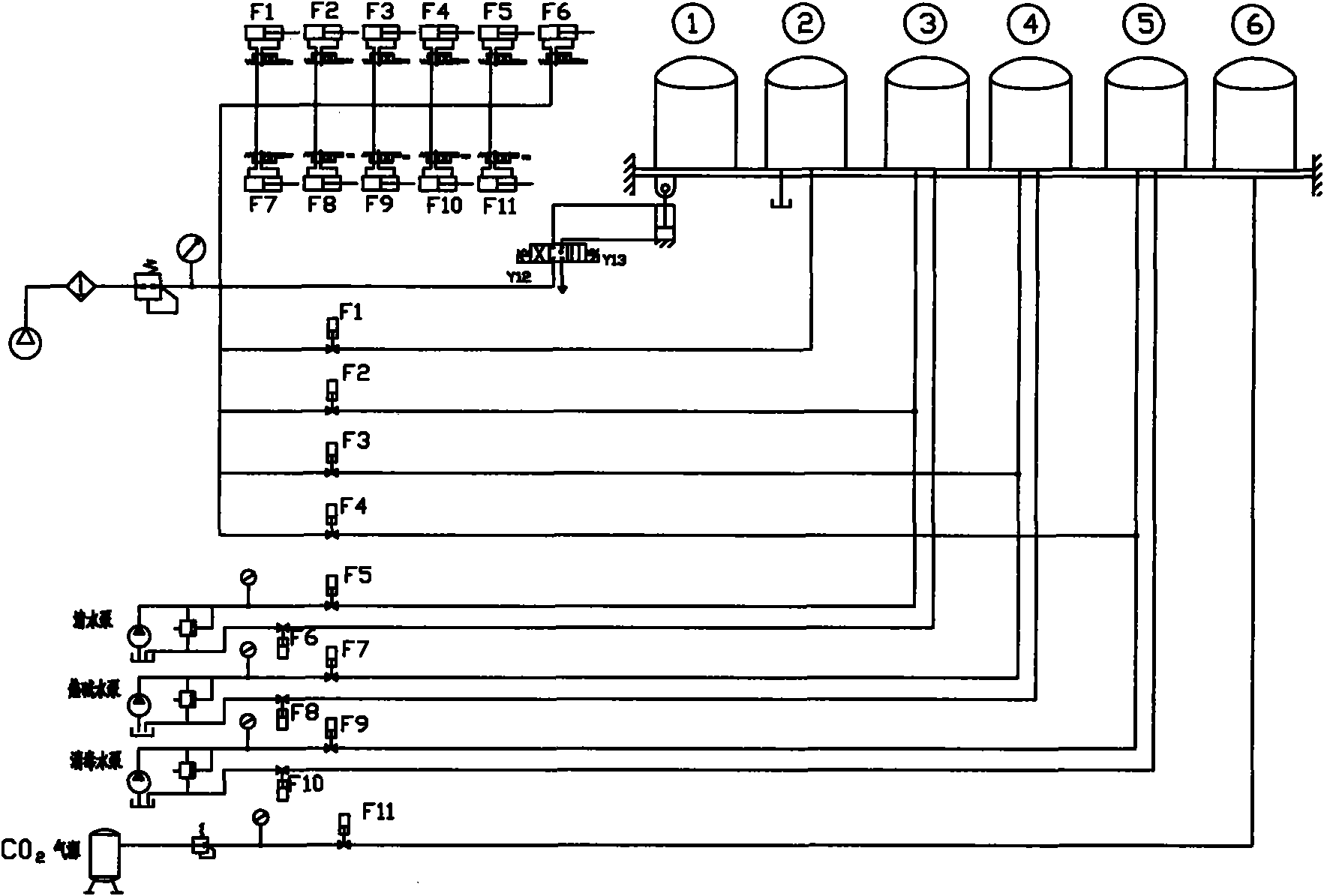

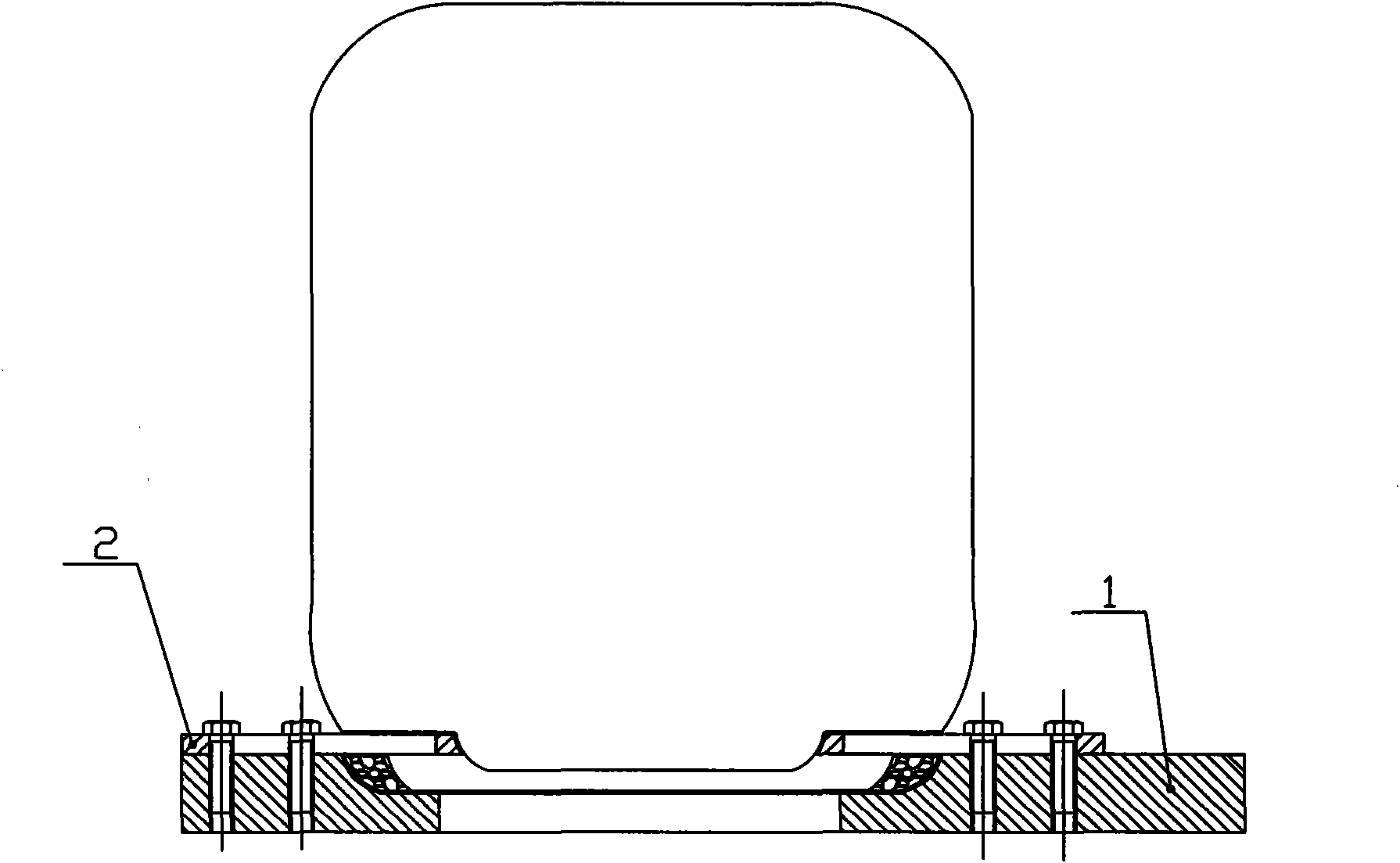

[0015] In the figure, 1. Draft beer keg holder, 2. Fixtures (12 pieces), 3. Hose connector, 4. Cleaning head bracket, 5. Cylinder, 6. Coupling, 7. Rack, 8. Drive Motor, 9. Motor mounting base, 10. Bracket, 11. Cleaning head, 12. Drive shaft, 13. Bucket support bracket; For residual wine, ③ is water in and out, ④ is hot alkaline water in and out, ⑤ is disinfected water in and out, ⑥ is carbon dioxide back pressure; F1-F11 are 11 pneumatic valves; YA1-YA11 are 11 two-position four-way solenoid valves The electromagnets, YA12 and YA13 are the two electromagnets of the three-position four-way reversing valve.

[0016] Such as figure 1 As shown, the drive shaft 12 is equipped with the middle part of the frame 7, and the cleaning head bracket 4 and the bucket bracket 13 are installed on the driving shaft 12. Six stations are equidistantly arranged on the cleaning head bracket 4, of which five stations are Fix five cleaning heads 11 with bolts, and the other is an empty space. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com