Method for deoxidizing and alloying molten steel

An alloying and molten steel technology, applied in the field of metallurgical technology, can solve the problems of low alloy yield, poor deoxidation effect, and inaccurate calculation of alloy addition amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

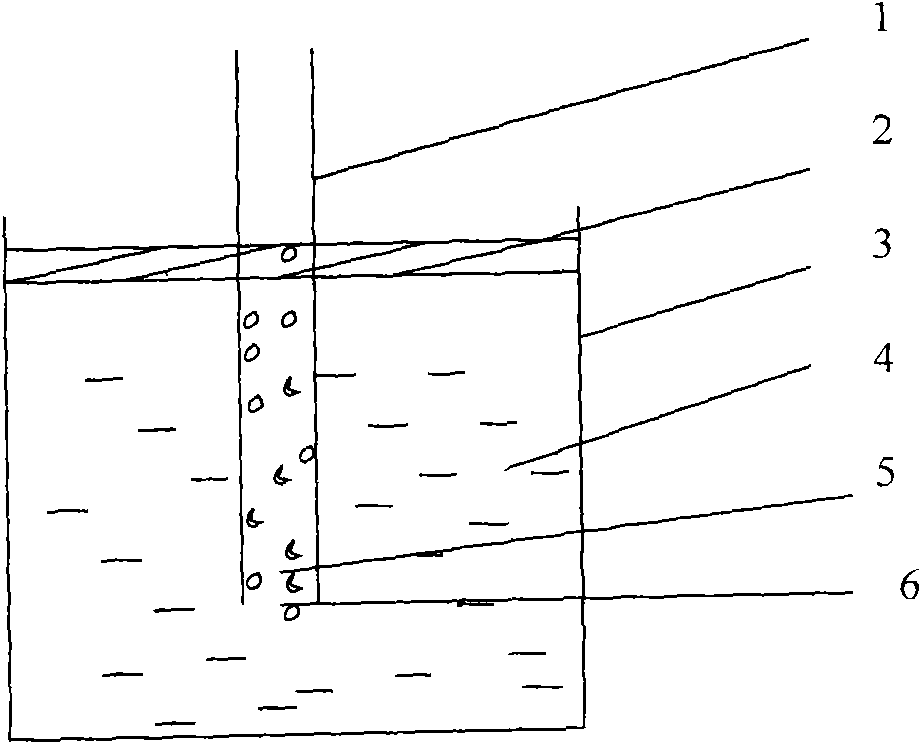

[0043] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

[0044] Specific examples: the known carbon content is 0.1%, the tapping temperature is 1600°C, the ferrosilicon is deoxidized, the molten steel oxygen content is 0.025% at the end of smelting, the finished molten steel contains 0.27% silicon, and the ferrosilicon contains 50% silicon.

[0045] 1. Calculate the amount of ferrosilicon added

[0046] Silicon consumed by deoxidation: 0.013%

[0047] Silicon in finished molten steel: 0.27%

[0048] Silicon required for deoxidation and alloying per ton of molten steel: 0.013%+0.27%=0.283%

[0049] The amount of ferrosilicon that should be added per ton of steel for deoxidation and alloying is 5.66kg

[0050] 2. The converter slag stopper or slag stop ball is tapped. After tapping, ladle protective slag is added to the surface of the ladle. The amount of molten steel per ton is 1kg-1.5kg.

[0051] 3. Insert the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com