Special round heating furnace for fan

A heating furnace and circular technology, which is applied in the field of fan-specific circular heating furnaces, can solve the problems of large floor area, large supporting power, and inconvenient operation, and achieve small floor space, small supporting power, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

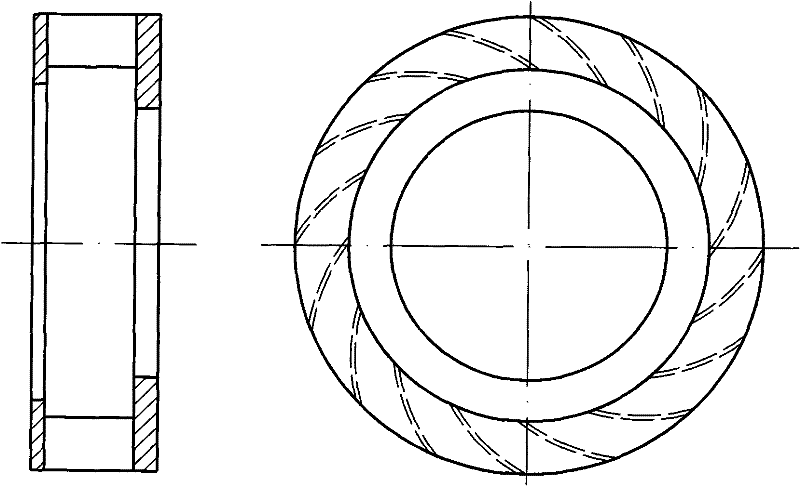

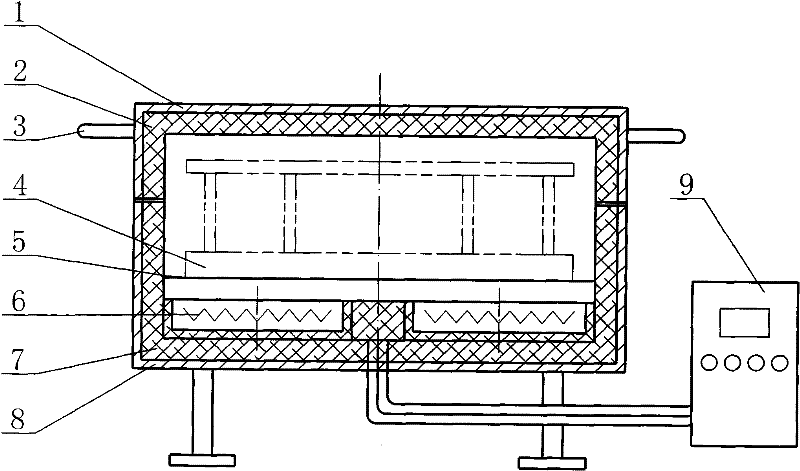

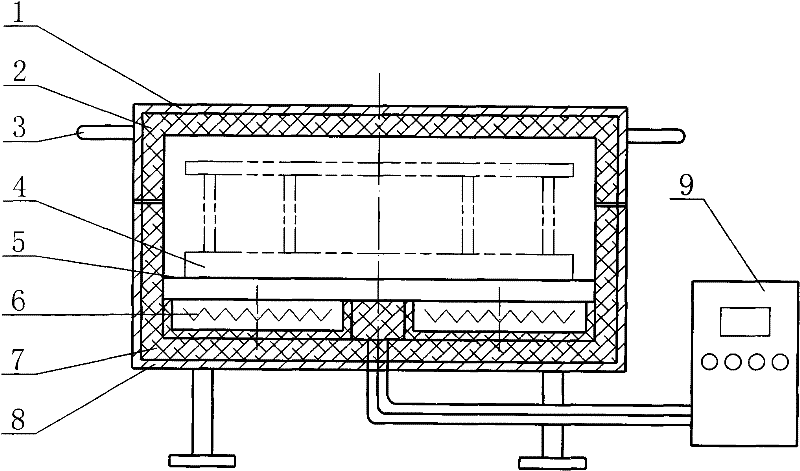

[0025] The following combined with the accompanying drawings figure 2 The present invention is described further, as two kinds of fans of preheating Φ845 * 175 and Φ745 * 170, can realize technical scheme of the present invention by following method:

[0026] ①, δ5~δ6 steel plate blanking, the size of the circular steel plate blanking is about 300 larger than the diameter of the fan, welded into an upper and lower openable circular upper cover shell (sequence 1), a circular lower seat shell (sequence 8), The inner space height of the upper and lower shells is about 200 higher than that of the fan;

[0027] ②. Weld two upper cover handles (serial 3) next to the upper cover shell (sequence 1) to prepare for removing the upper cover during operation;

[0028] ③. Evenly distribute and weld 8 load-bearing partitions in the shell of the lower seat (sequence 5);

[0029] ④. Install high-grade thermal insulation cotton in the shell of the upper cover (sequence 2), and install high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com