Electric main shaft supported by adopting aerostatic bearing

A bearing support and gas static pressure technology, applied in metal processing equipment and other directions, can solve the problems of increased processing and assembly difficulty, poor adaptability to the use environment, and a large number of parts, and achieve the effect of simplifying the structure and improving the adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

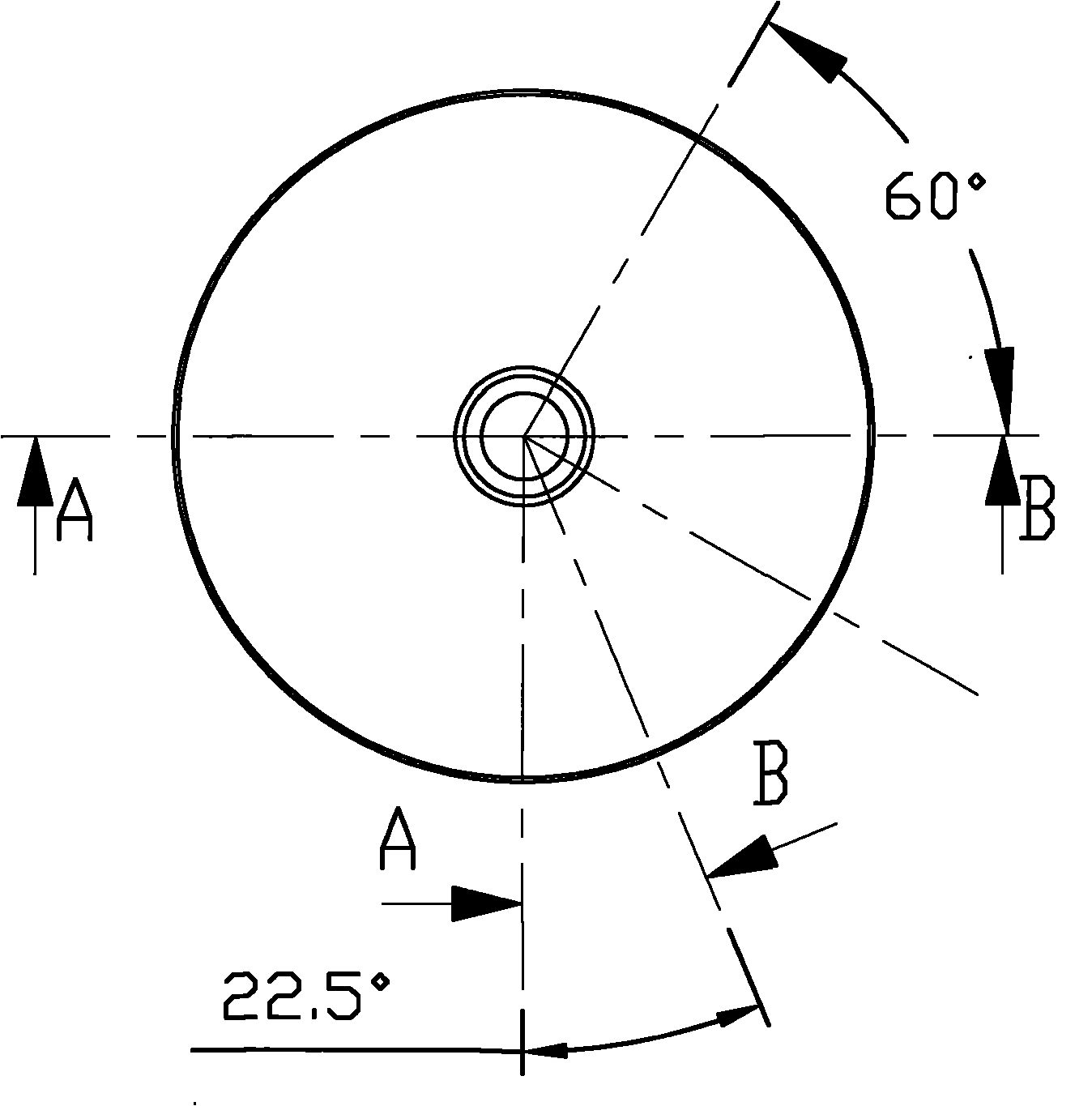

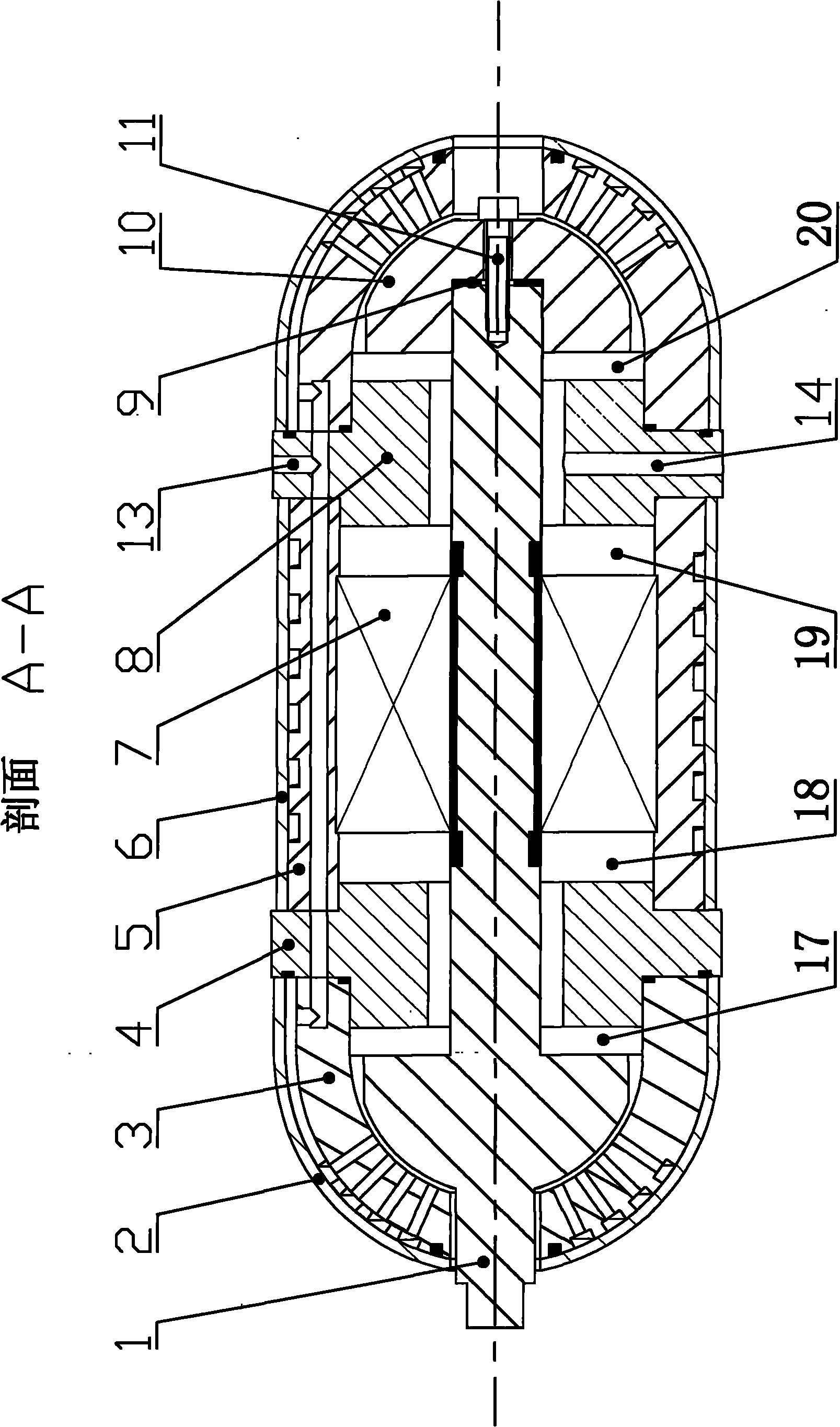

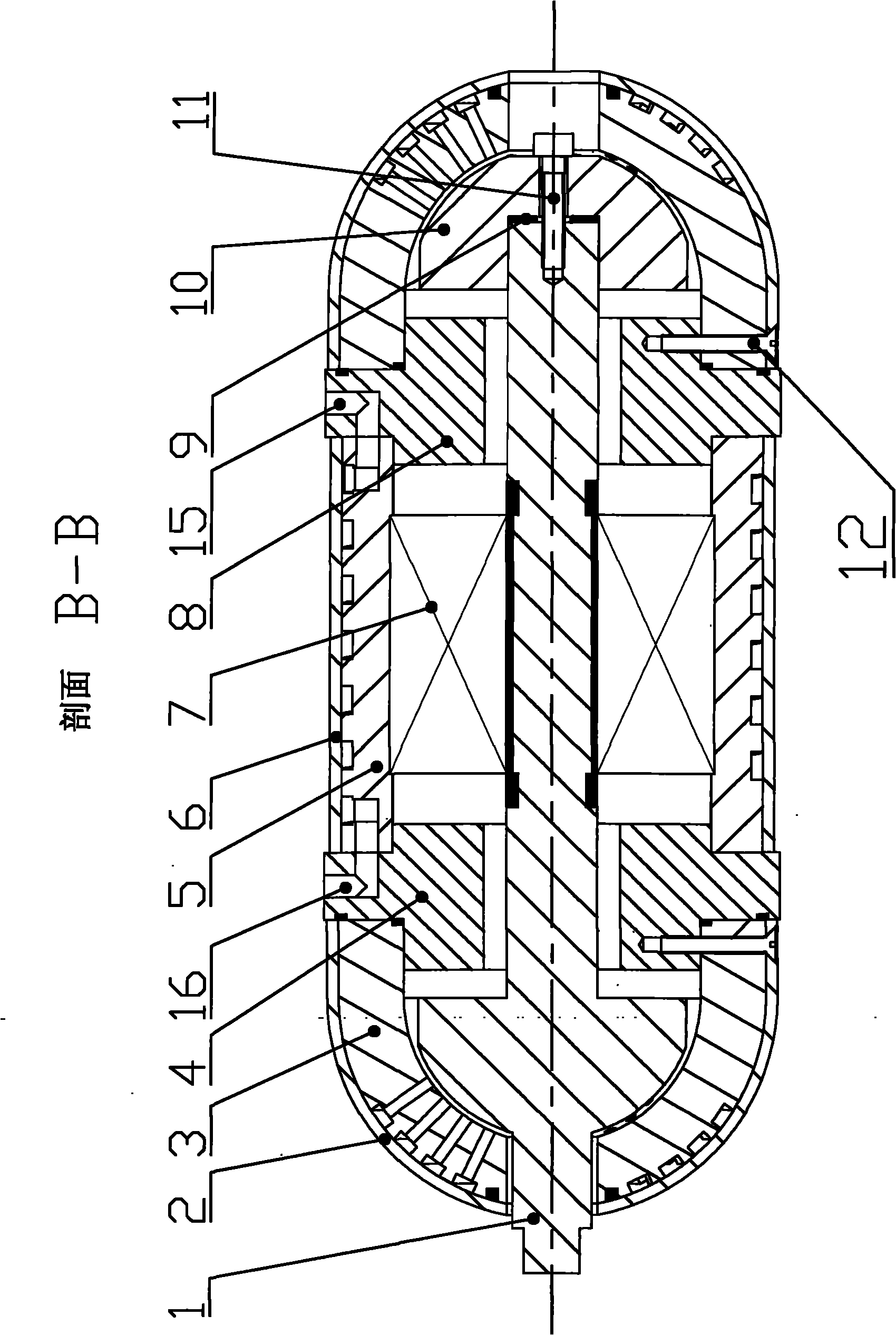

[0018] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-3 As shown, an electric spindle supported by aerostatic bearings includes a shaft body 1, a front flange 4, a housing inner sleeve 5, a housing outer sleeve 6, a stator 7, a rear flange 8, and a supported hemisphere; The housing inner sleeve 5 and the housing outer sleeve 6 described above are combined to form a housing, and the front flange 4 and the rear flange 8 are respectively arranged at the front and rear ends of the housing, and constitute a body including a water circulation cooling channel, and the stator 7 is installed In the body, a shaft body 1 is installed at the through hole in the middle of the stator 7; the front section of the shaft body 1 is in the shape of a hemisphere, forming a front supporting hemisphere, and the rear end of the shaft body 1 is connected with the rear supporting hemisphere 10 through an axial screw 11, so that Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com