Roll-on device and method for large fixed type rotary crane

A crane and fixed technology, applied in the direction of cranes, hoisting devices, hoisting equipment braking devices, etc., can solve the problems of difficulty in ensuring the accuracy of floating crane operations, increasing the manufacturing cost of the whole machine, and prolonging the on-site operation time. Achieve the effect of saving user docks, low transportation and installation costs, and short installation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

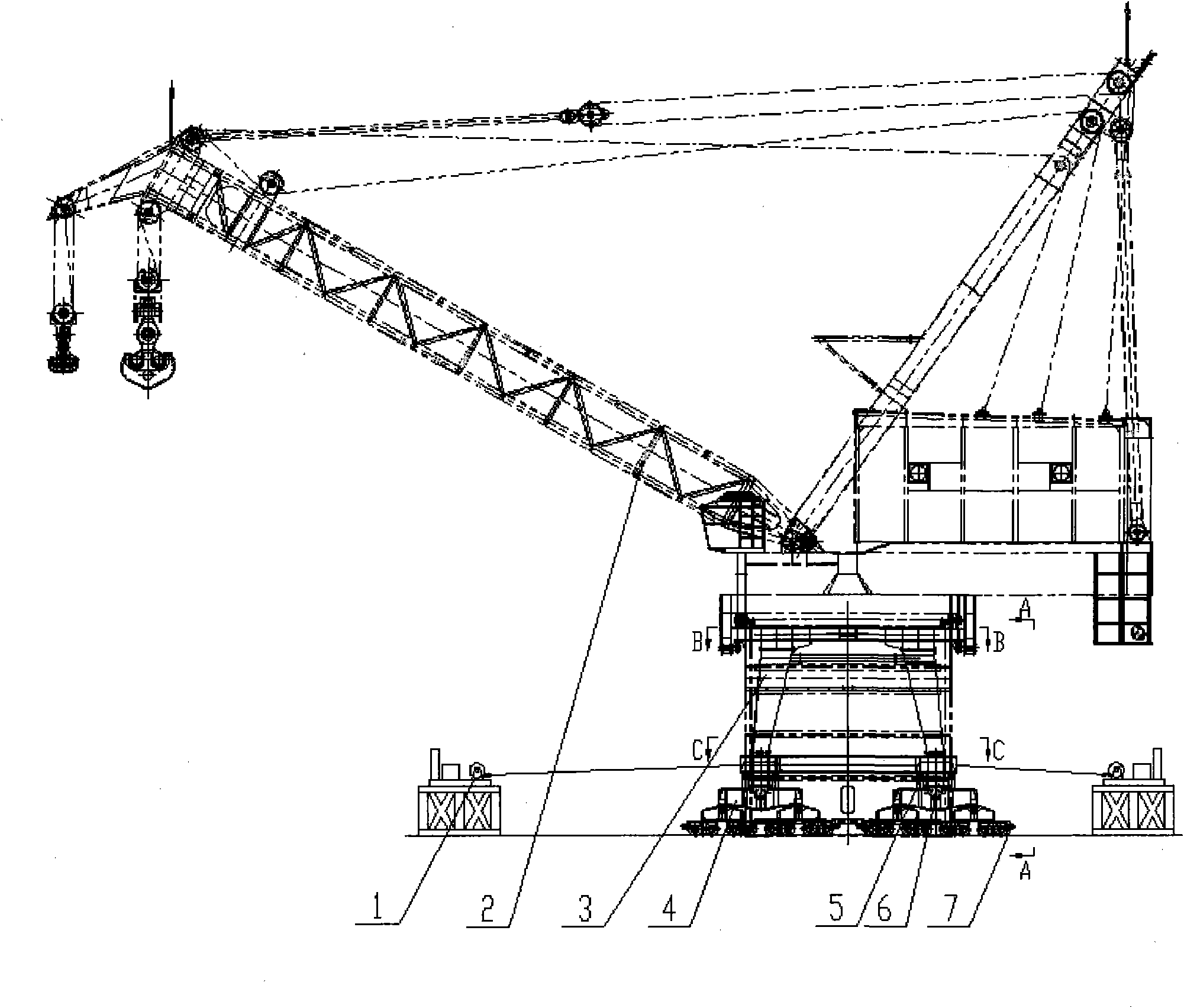

[0031] Such as Figure 1 to Figure 8 The shown roll-on-roll-off device for a large fixed slewing crane is mainly composed of a hoist 1 , a crane body 2 , a rigid mast 3 , a running trolley group 4 , a jack 5 , an adjustment pad 6 , and a wheel brake 7 .

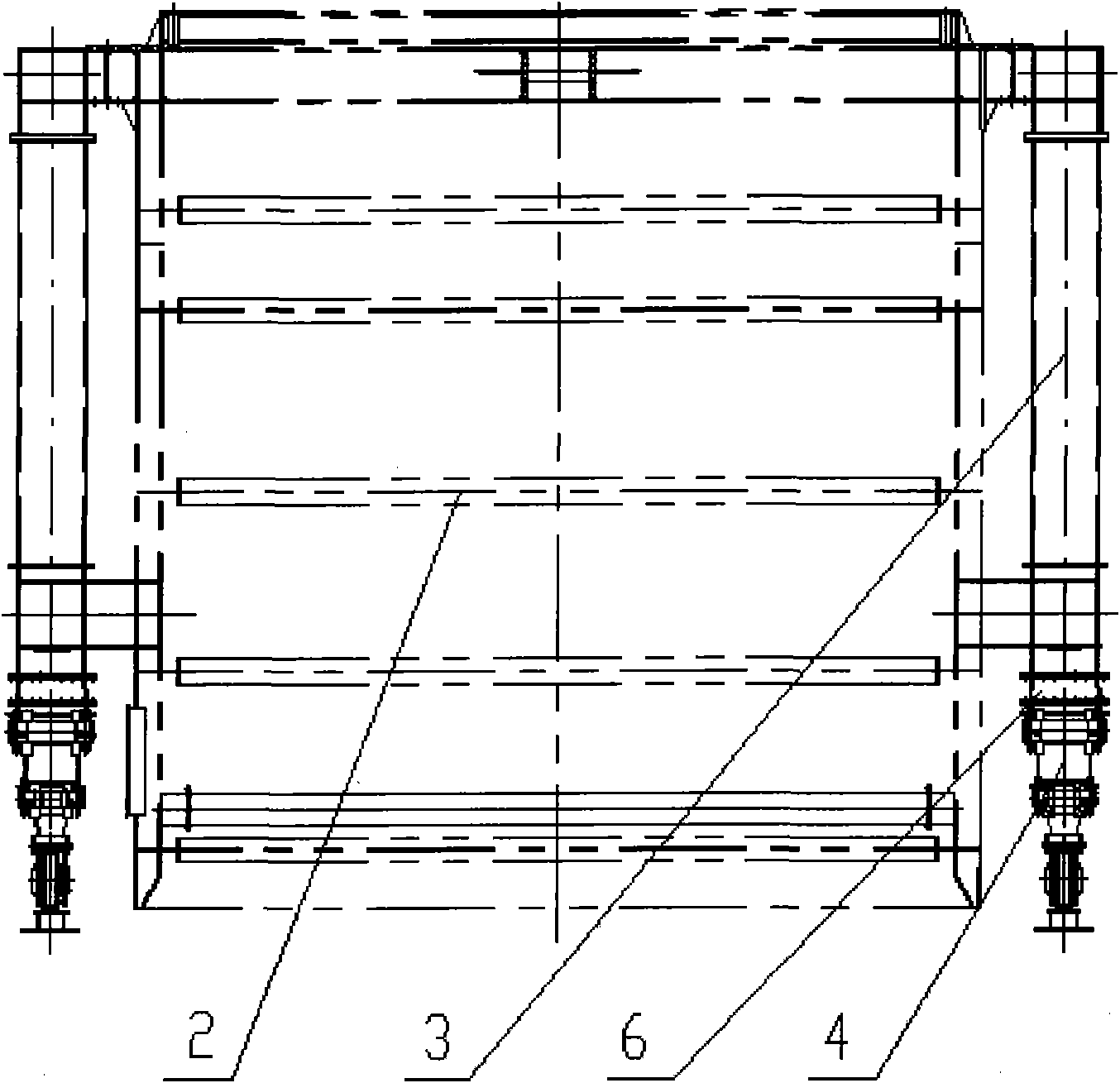

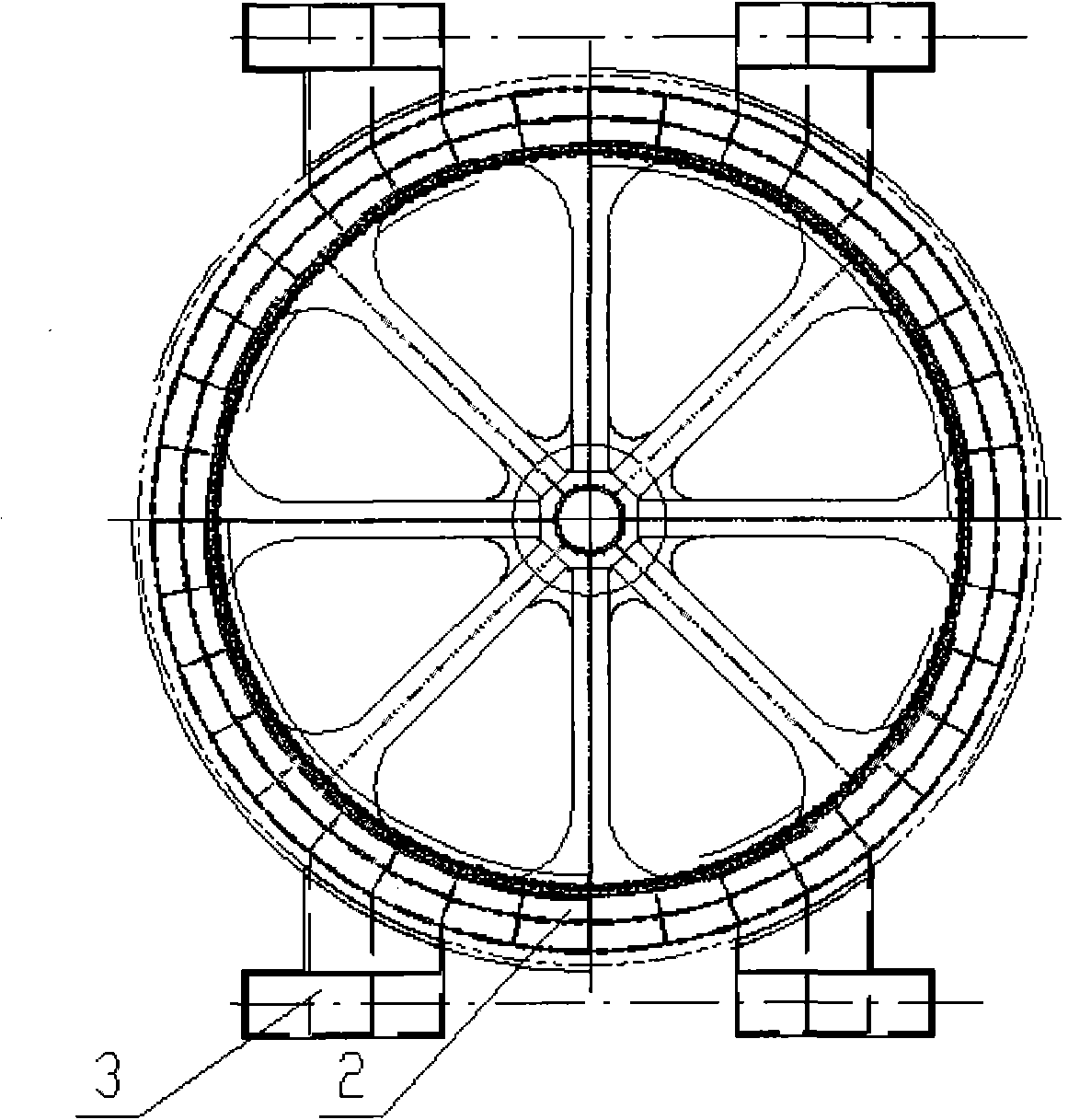

[0032] The crane main body 2 includes cylindrical steel structure 2.1, slewing support device 2.2, slewing turntable 2.3, jib frame 2.4, herringbone frame 2.5, machine room 2.6 and other components, see Image 6 Among them, the cylindrical steel structure 2.1 will be fixed to the user's dock, and the slewing support device 2.2 is used to connect the rotary turntable 2.3 and the cylindrical steel structure 2.1, the rotary turntable 2.3, the arm frame 2.4, the herringbone frame 2.5, and the machine room 2.6 The superstructure of equal composition can be 360 ° of revolutions around the center of revolution under the bearing of slewing support device 2.2. Boom 2.4 and herringbone frame 2.5 are respectively connected with slewi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com