Active orange dye composition

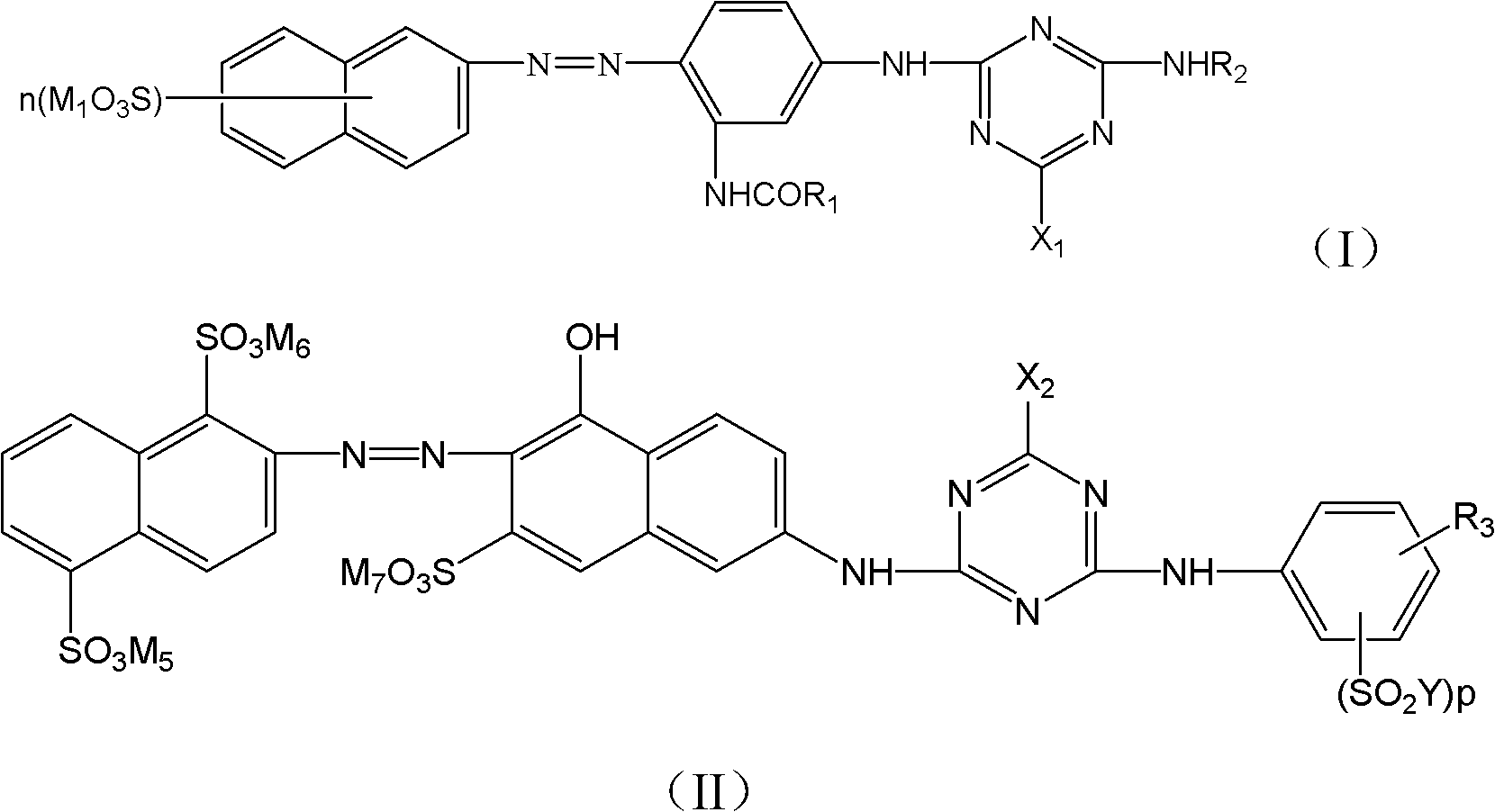

A composition and technology of orange dyes, applied in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems that the color fastness cannot meet the production requirements, the color fastness of dyed fabrics deteriorates, and the color fixation rate is low, etc., to achieve Bright color, high lift, high color fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

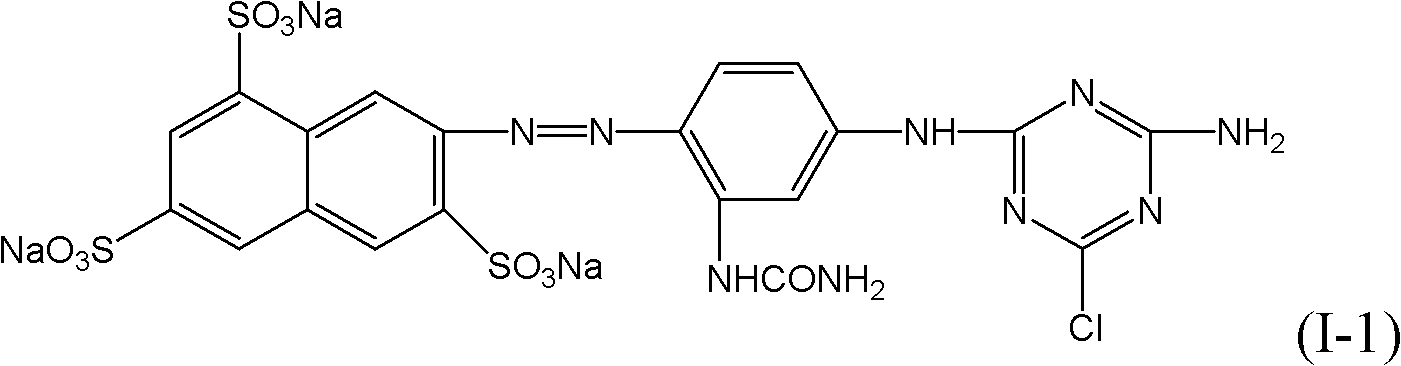

[0041] Mix 95 grams of component A of formula (I-1), 5 grams of component B of formula (II-1), 15 grams of sodium salt, and 5 grams of sodium lignosulfonate in a mixing tank for dry powder mixing, or dissolve together After drying, the reactive dye composition of the present invention can be obtained, and the dye can provide orange with excellent fastness properties to fabrics.

[0042]

[0043]

Embodiment 2

[0045] Mix 90 grams of component A of formula (I-2), 10 grams of component B of formula (II-2), and 15 grams of sodium bicarbonate in a mixing tank for dry powder mixing, or spray dry after dissolving together to obtain this product According to the reactive dye composition described in the invention, the dye can provide orange with excellent fastness properties to fabrics.

[0046]

Embodiment 3

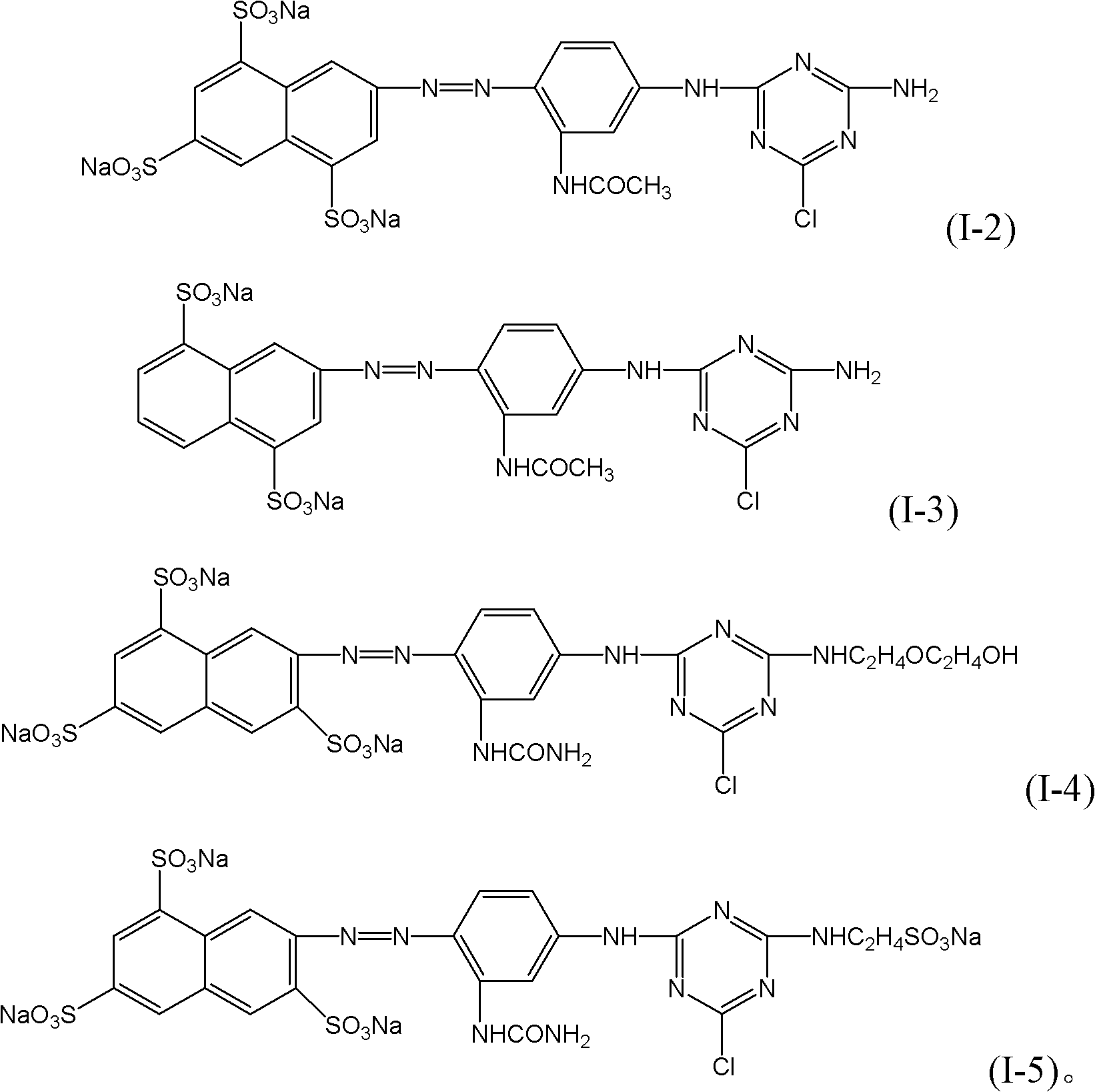

[0048]According to the method described in Example 1, the difference is that the structure and weight ratio of component A and component B in Table 1 are adopted. In addition, the addition amount of sodium bicarbonate is 20 grams, and mixing is carried out, and this product can also be obtained. According to the reactive dye composition described in the invention, the dyestuff can provide the orange hue with excellent fastness properties to the fabric.

[0049] Table 1

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com