Beta type gamma-TiAl alloy and preparation method thereof

A technology for alloys and master alloys, applied in the field of TiAl alloys and their preparation, can solve the problems of insufficient high-temperature deformation ability and oxidation resistance of TiAl-based alloys, achieve excellent oxidation resistance, realize industrial production, and have simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0012] Specific Embodiment 1: In this embodiment, the β-type γ-TiAl alloy contains 41% to 46% of Al, 9% of V and Nb, 0% to 0.3% of Y and the balance of Ti in terms of atomic percentage, wherein V The ratio x to the atomic percent content of Nb=0.5-5.

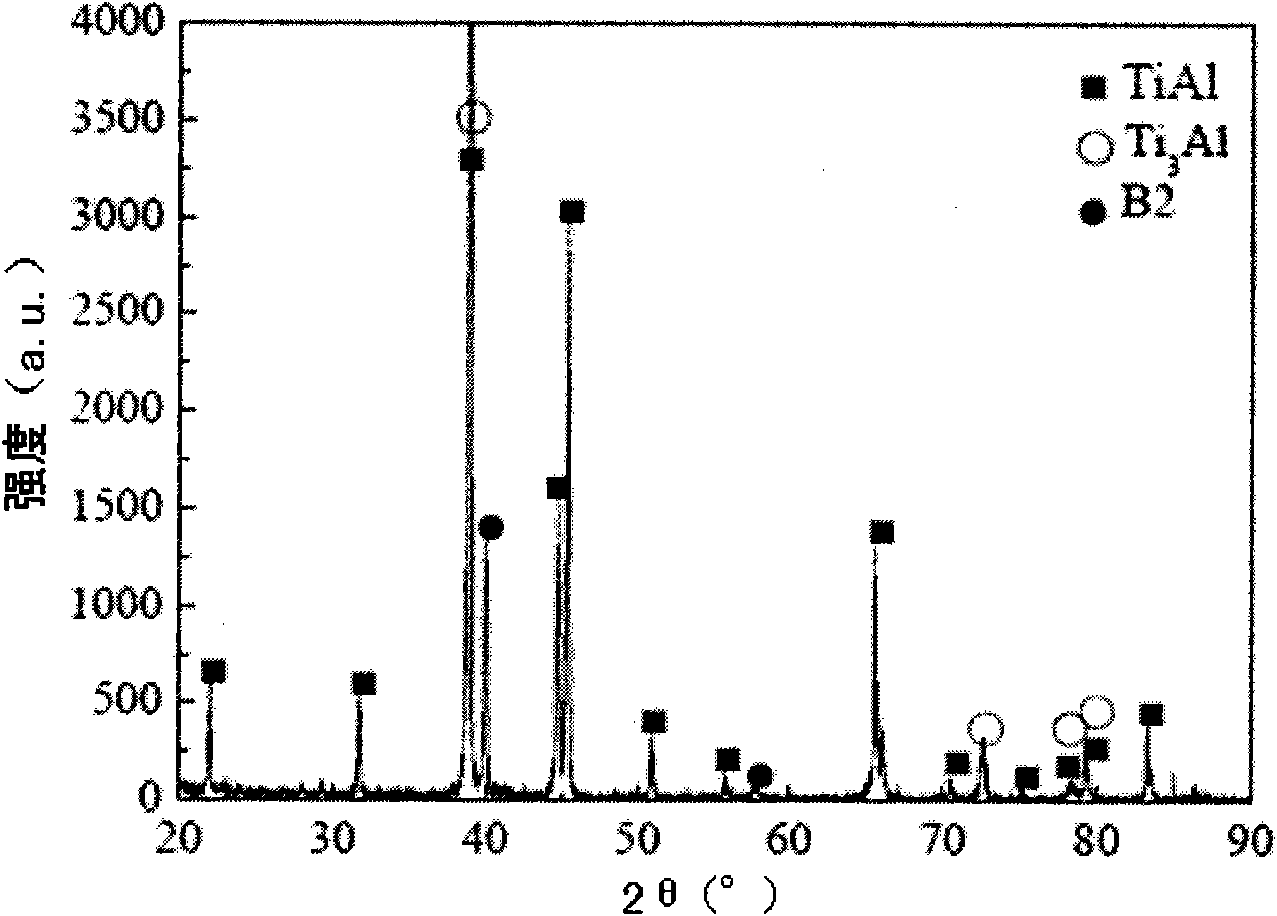

[0013] The nominal chemical composition of the β-type γ-TiAl alloy of this embodiment is Ti-(41-46)Al-(9~9.3)(V, Nb, Y) (at.%), mainly containing γ-TiAl, α 2 -Ti 3 Al and β(B2) phases. Adding an appropriate amount of Y element in the present invention can significantly refine the grain and layer spacing of the TiAl alloy, and at the same time control the reasonable ratio of V and Nb content (x=0.5~5), so that the β-type γ-TiAl alloy has a good Mechanical properties and high temperature deformability.

[0014] The atomic percentage of Nb in the β-type γ-TiAl alloy of this embodiment is 1.5%-6%, and the atomic percentage of V is 9%-Nb% (atomic percentage of Nb).

[0015] The X-ray diffraction spectrum of the β-type γ-TiAl allo...

specific Embodiment approach 2

[0016] Embodiment 2: This embodiment differs from Embodiment 1 in that the β-type γ-TiAl alloy contains 41% to 46% of Al, 9% of V and Nb, and the balance of Ti. Other parameters are the same as in the first embodiment.

[0017] The nominal chemical composition of the β-type γ-TiAl alloy of this embodiment is Ti-(41-46)Al-9(V, Nb) (at.%).

specific Embodiment approach 3

[0018] Embodiment 3: This embodiment differs from Embodiment 1 in that the β-type γ-TiAl alloy contains 43% to 46% of Al, 9% of V and Nb, and the balance of Ti. Other parameters are the same as in the first embodiment.

[0019] The nominal chemical composition of the β-type γ-TiAl alloy of the present embodiment is Ti-(43-46)Al-9(V,Nb)(at.%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com