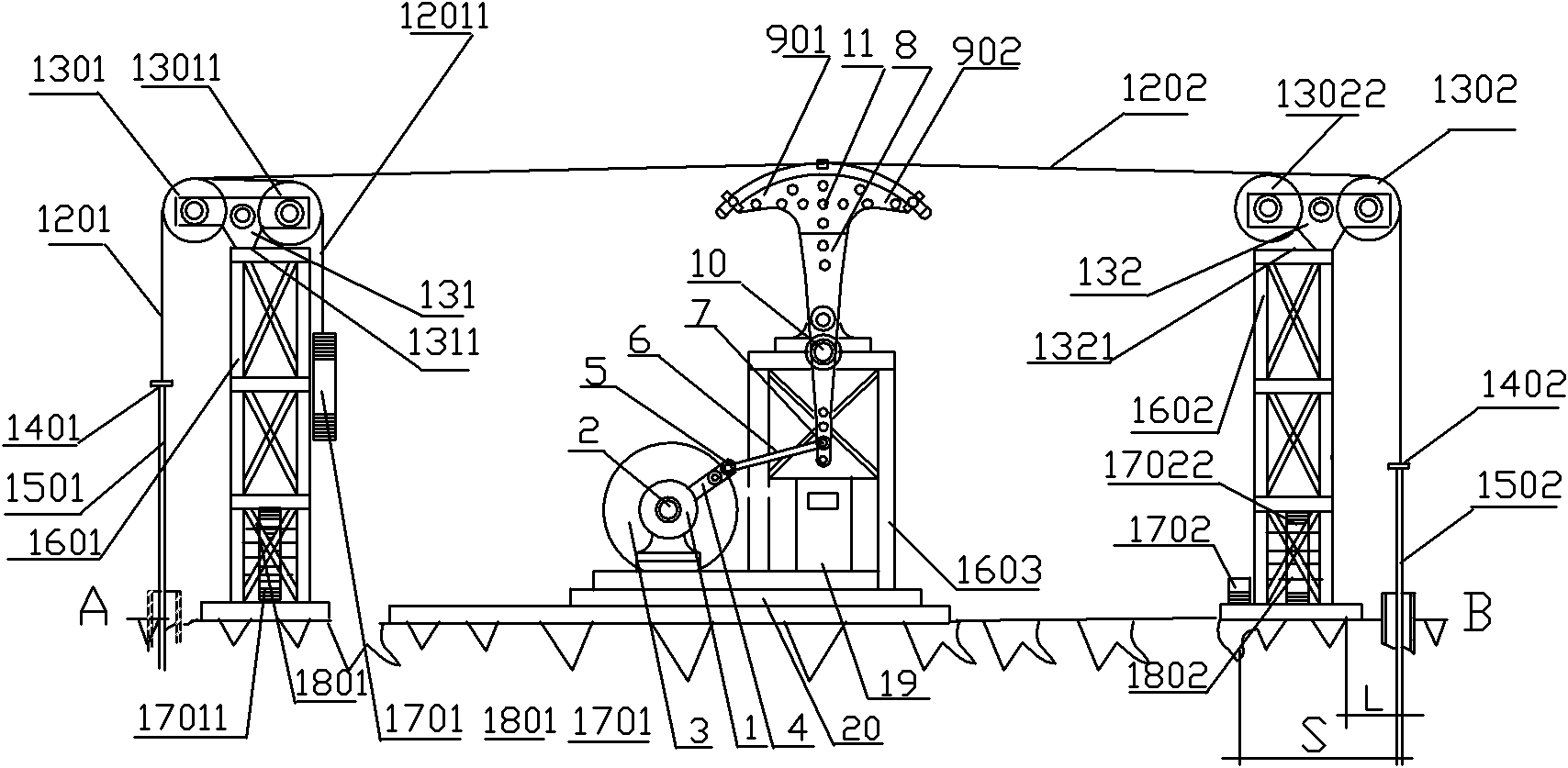

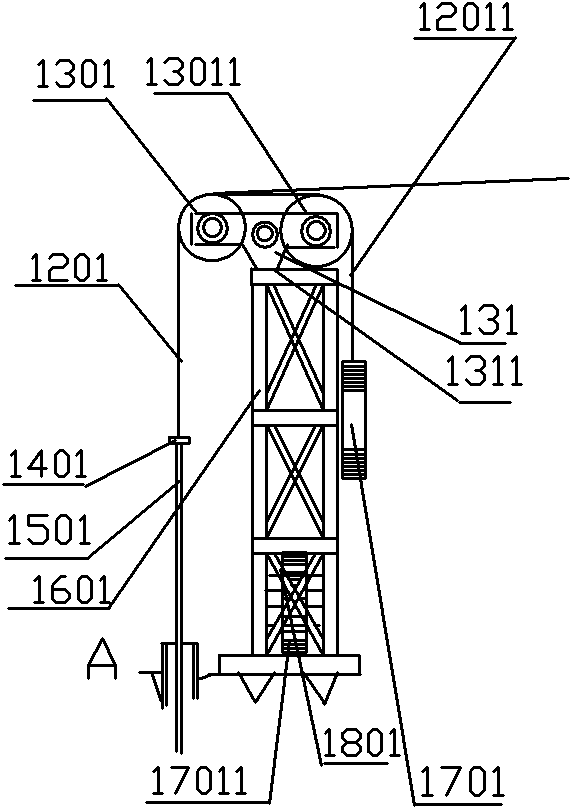

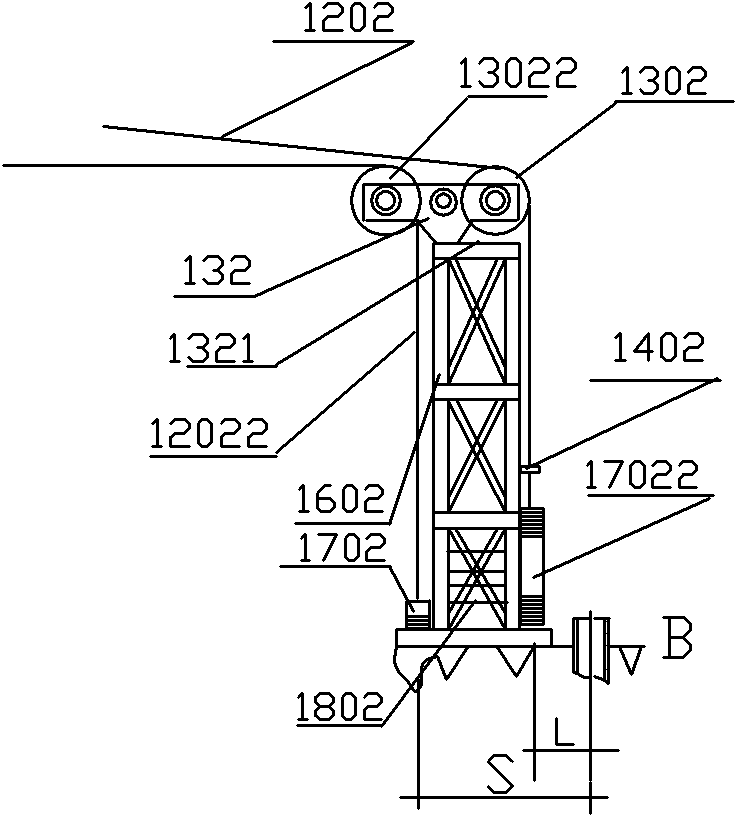

Swinging double-well pumping unit

A pumping unit and swing type technology, which is applied in the field of coaxially connected multi-point drive double-arranged oil well pumping units, can solve the problems of complicated controllers, frequent forward and reverse rotation costs, and ineffective energy, and achieve daily maintenance costs. The effect of reducing, ensuring service life and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0046] The swing type double-well array pumping unit used in double-row wells, such as Figure 5 As shown, the clutch 21, the coupling 22, the clutch pedal 23, the clutch 21 is provided with a crank wheel 3, a crank arm 4, (crank arm) pin 5; the coupling 22 connects the motor 1 The transmission shaft 2 is connected at multiple points. When the load is removed, the clutch pedal 23 is disengaged to transmit torque. The transmission power of the row of double-row wells is forward and reverse.

Embodiment 3

[0048] Such as Image 6 As shown, another structure of the swing double-well (arrangement) pumping unit applied to double wells or double-row wells still uses the crank wheel as the core component of the transmission mechanism, and the synchronous motor shaft is also coaxial with the crank wheel. It can be the output shaft of the reducer, but this type of swing double-well (arranged) pumping unit is especially suitable for the use of dual-well load balance, especially for small pumping units with small strokes and high strokes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com