Closed loop control system for temperature and components of RH (Rockwell Hardness) molten steel

A technology of molten steel temperature and closed-loop control, which is applied in the general control system, control/regulation system, program control, etc., can solve the problems of low measurement data requirements, complex mechanism, and influence of analysis results, and achieve accurate forecasting, standardized operation, and automation high level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

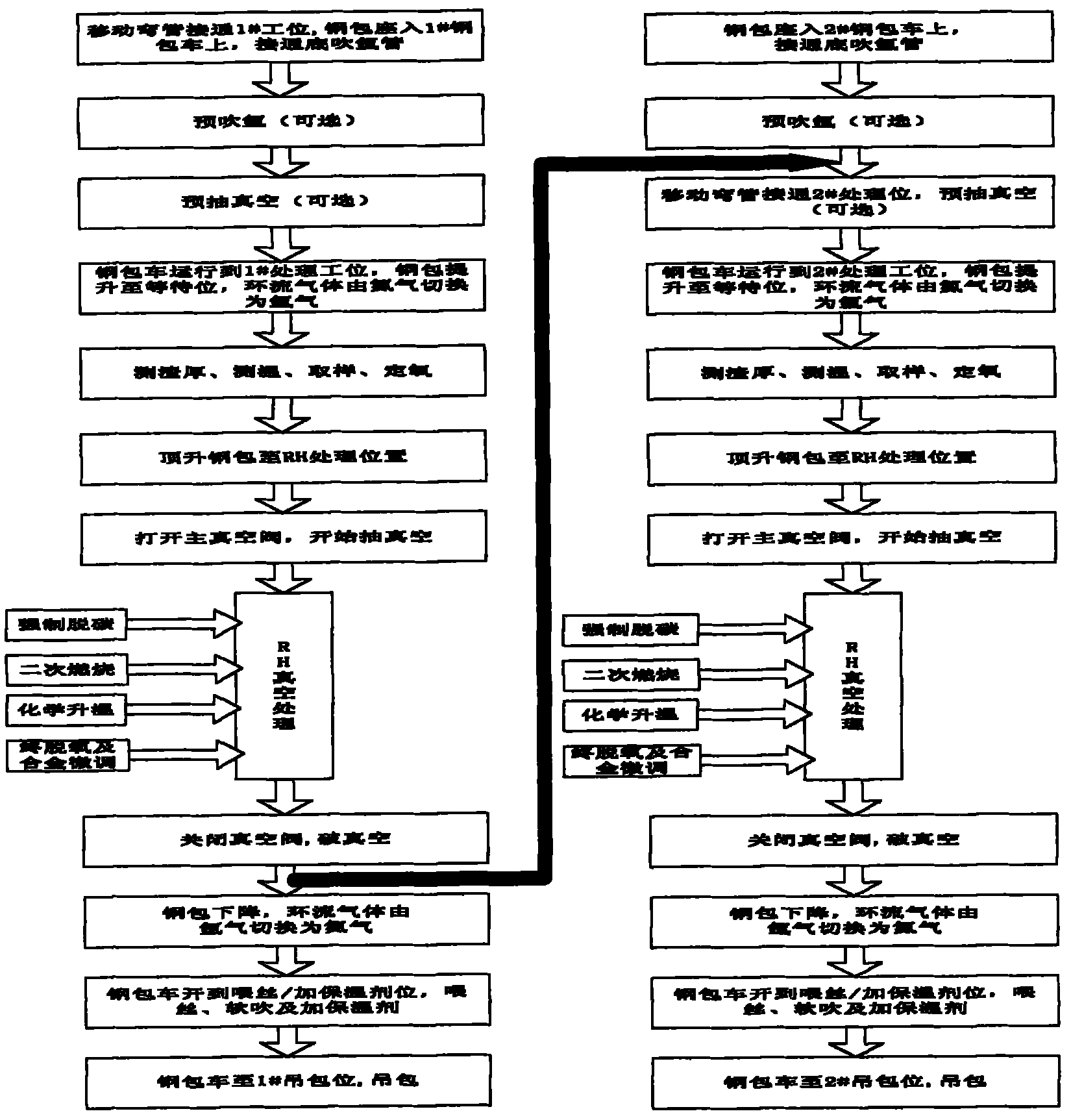

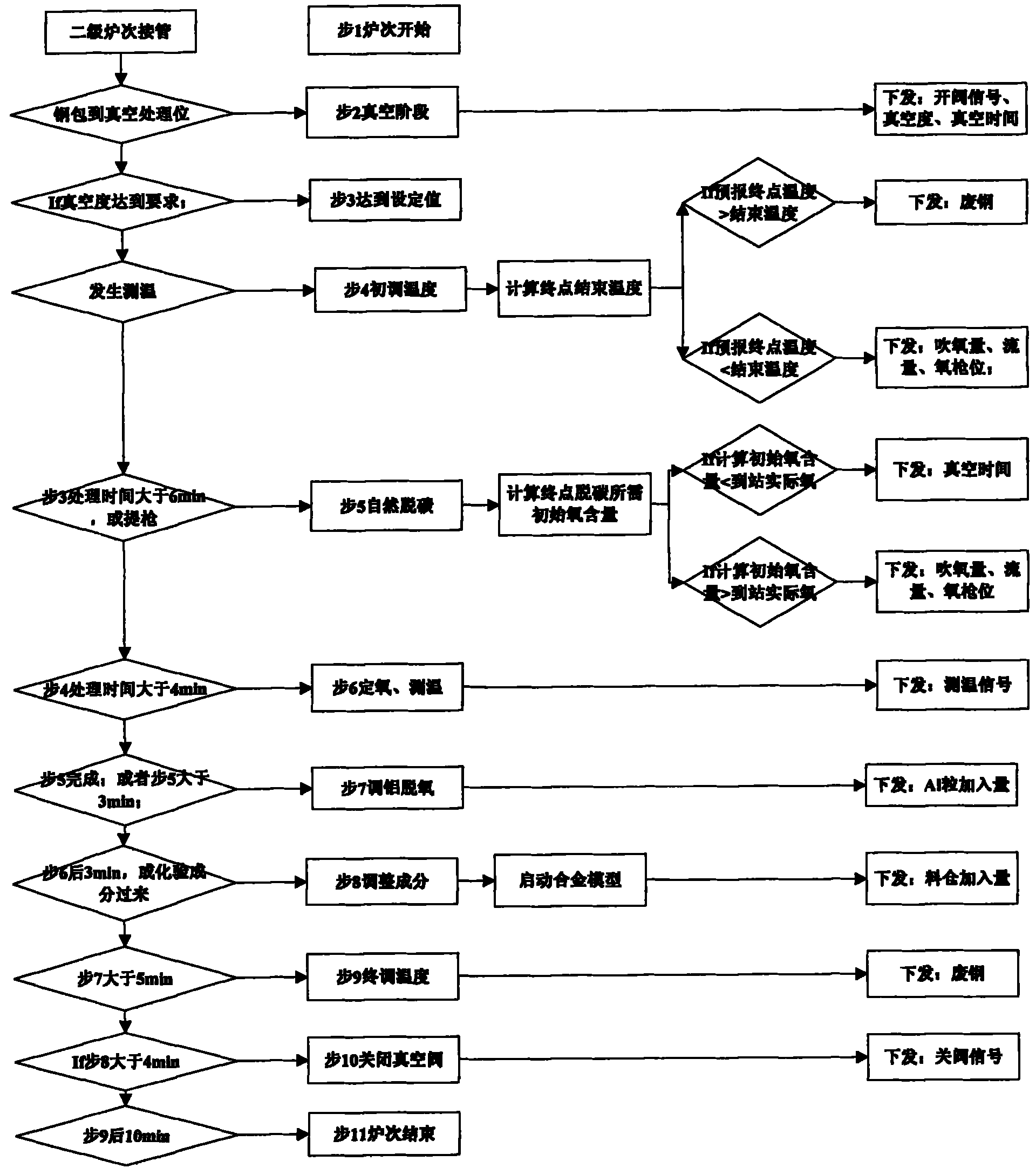

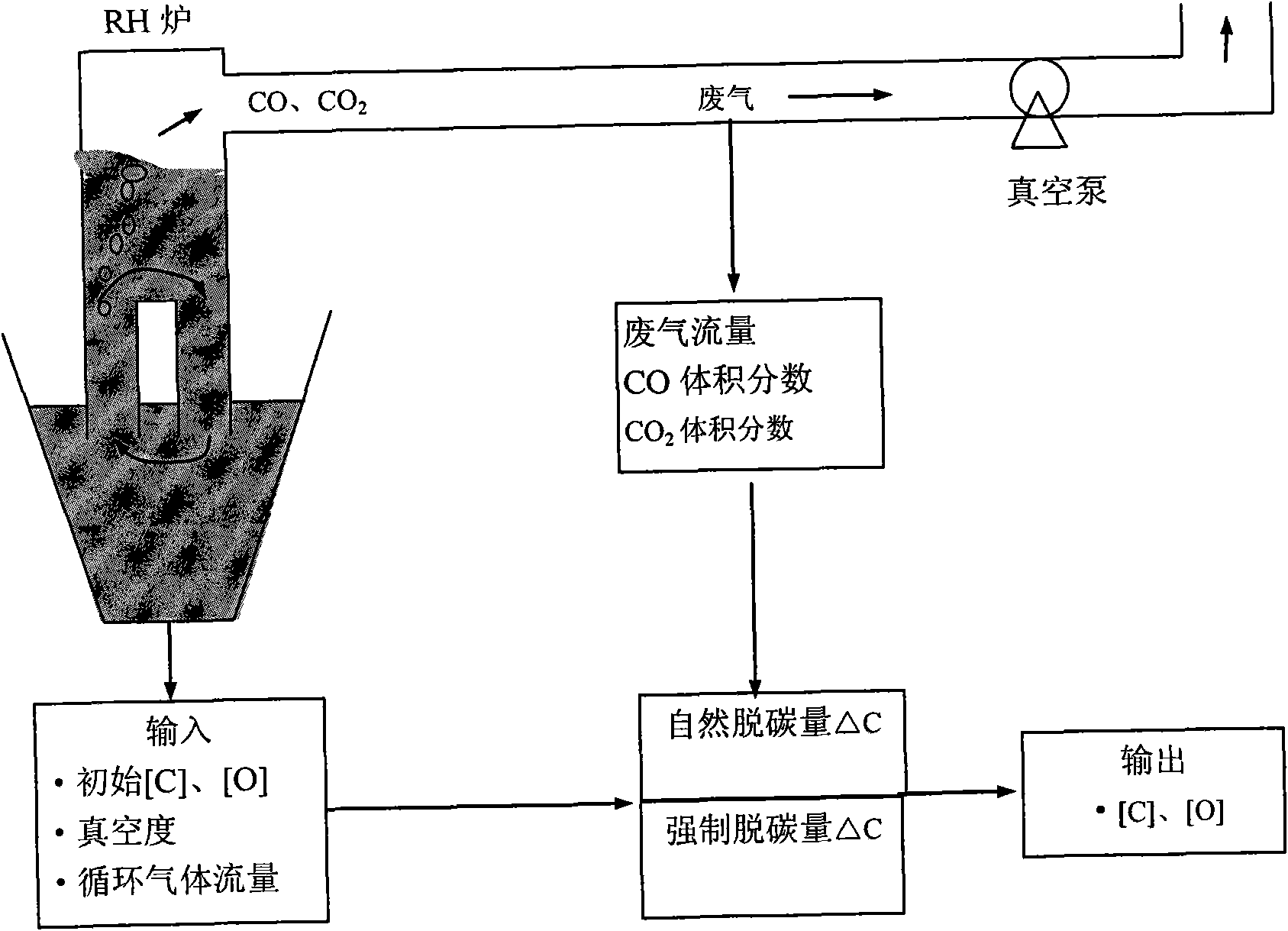

[0045] The system automatically collects production information, assay components, and production plans through the L1 and L3 communication modules, and writes them into the L2 database; the monitoring module uses the information collected by the communication module to automatically judge each smelting step, and then starts the calculation of the set value; The carbon module is based on metallurgical principles and empirical operations, and provides real-time forecasting; the self-learning module uses statistics, analysis, and optimization of system parameters.

[0046] 1, the described closed-loop control system, concrete realization method is as follows:

[0047] The RH closed-loop control system is developed with VC and stored in ORACLE database. It is divided into two parts: client and background system. The background system includes dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com