Manufacturing method of phase-changing random access memory

A technology for accessing memory and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of device quality degradation, loss of dielectric layers and polysilicon pillars, etc., and achieve the effect of overcoming short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

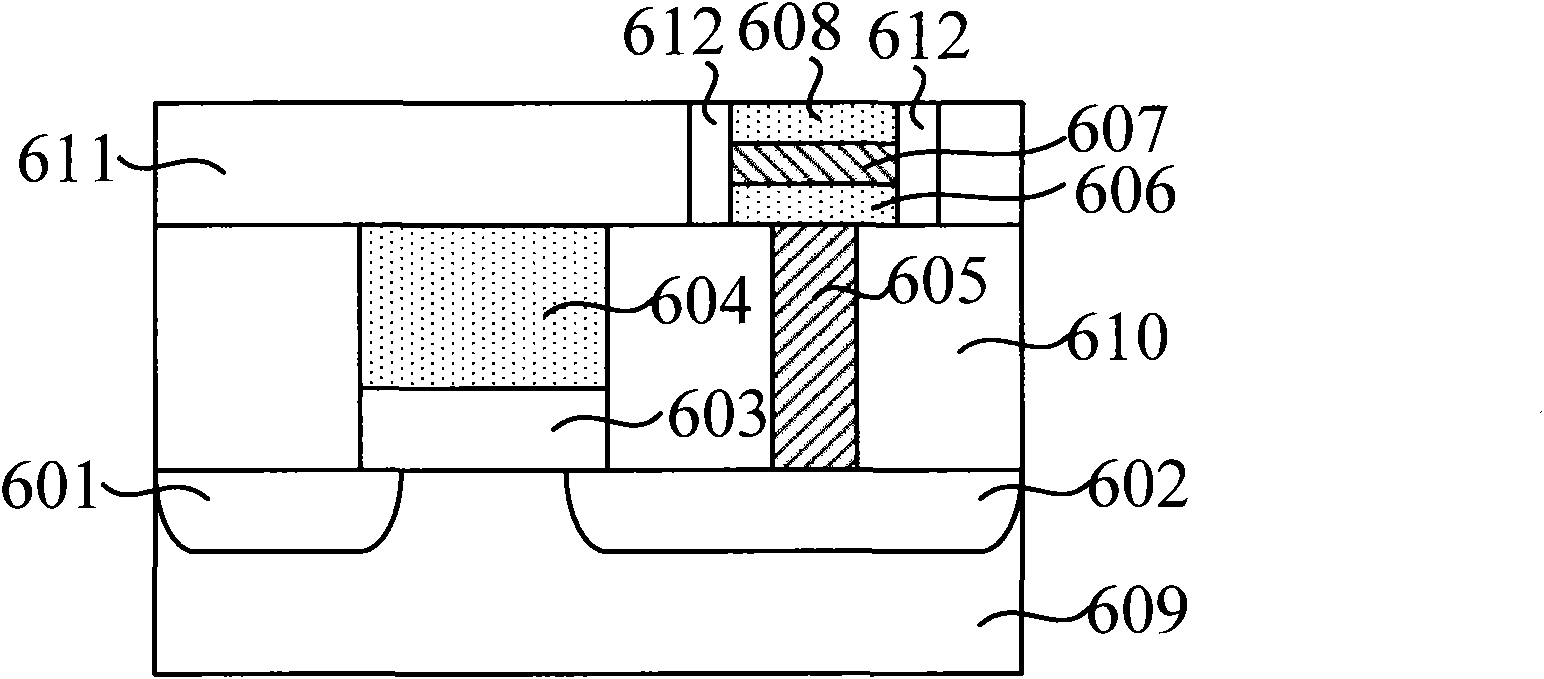

Embodiment Construction

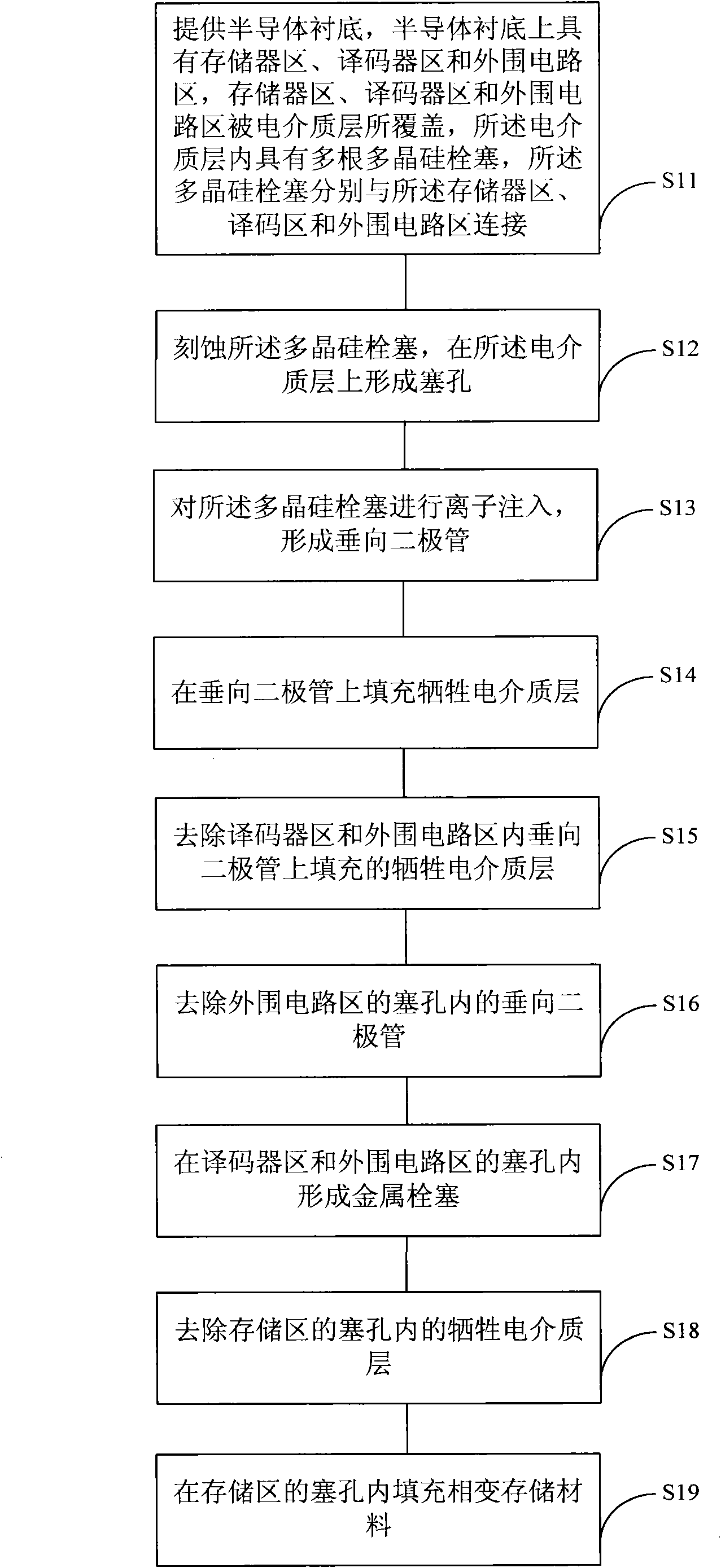

[0028] In one embodiment of the present invention, a method for manufacturing a phase change random access memory is provided, such as figure 2 shown, including steps:

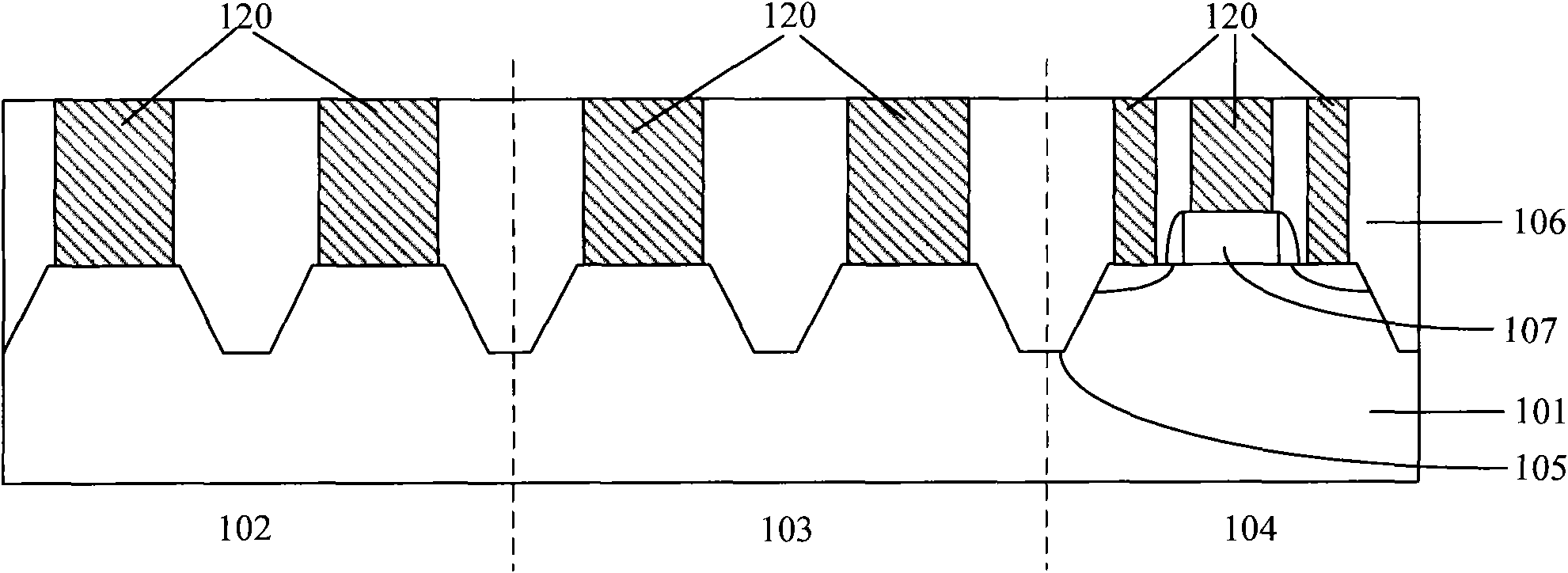

[0029] S11, providing a semiconductor substrate with a memory area, a decoder area, and a peripheral circuit area on the semiconductor substrate, the memory area, the decoder area, and the peripheral circuit area are covered by a dielectric layer, and there are multiple polysilicon roots in the dielectric layer Plugs, the polysilicon plugs are respectively connected to the memory area, the decoding area and the peripheral circuit area;

[0030] S12, etching the polysilicon plug to form a plug hole on the dielectric layer;

[0031] S13, performing ion implantation on the polysilicon plug to form a vertical diode;

[0032] S14, filling a sacrificial dielectric layer on the vertical diode;

[0033] S15, removing the sacrificial dielectric layer filled on the vertical diode in the decoder area and the peripher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com