Process for production of fabrics, fabrics and textile goods

一种制造方法、布帛的技术,应用在布帛的制造以及布帛及纤维制品领域,能够解决尚未提出审美性布帛等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

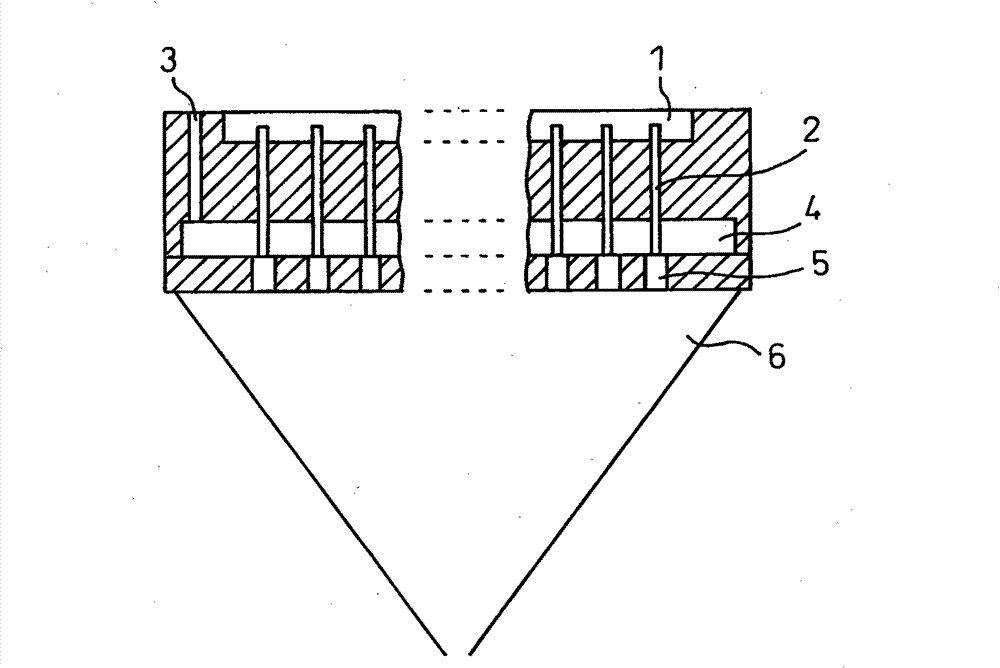

[0067] Polyethylene terephthalate was used as the island component, and 6 mol% of 5-sodium isophthalate and 6% by weight of polyethylene glycol with a number average molecular weight of 4000 were used as the sea component. Polyethylene terephthalate (dissolution speed ratio (sea / island)=230), with spinning temperature 280 ℃, spinning speed 1500m / min melt spinning goes out to sea: island=40:60, number of islands= 500 island-in-the-sea composite undrawn fibers were temporarily wound. The obtained undrawn yarn was subjected to roll drawing (roll drawing) at a drawing temperature of 80° C. and a draw ratio of 2.5 times, and then heat-set at 150° C. and wound up. The obtained island-in-the-sea composite drawn yarn was 56 dtex / 10fil, and the cross-section of the fiber was observed with a transmission electron microscope TEM. As a result, the shape of the islands was circular, and the diameter of the islands was 520 nm. The polyethylene terephthalate multifilament 56dtex / 10fil was m...

Embodiment 2

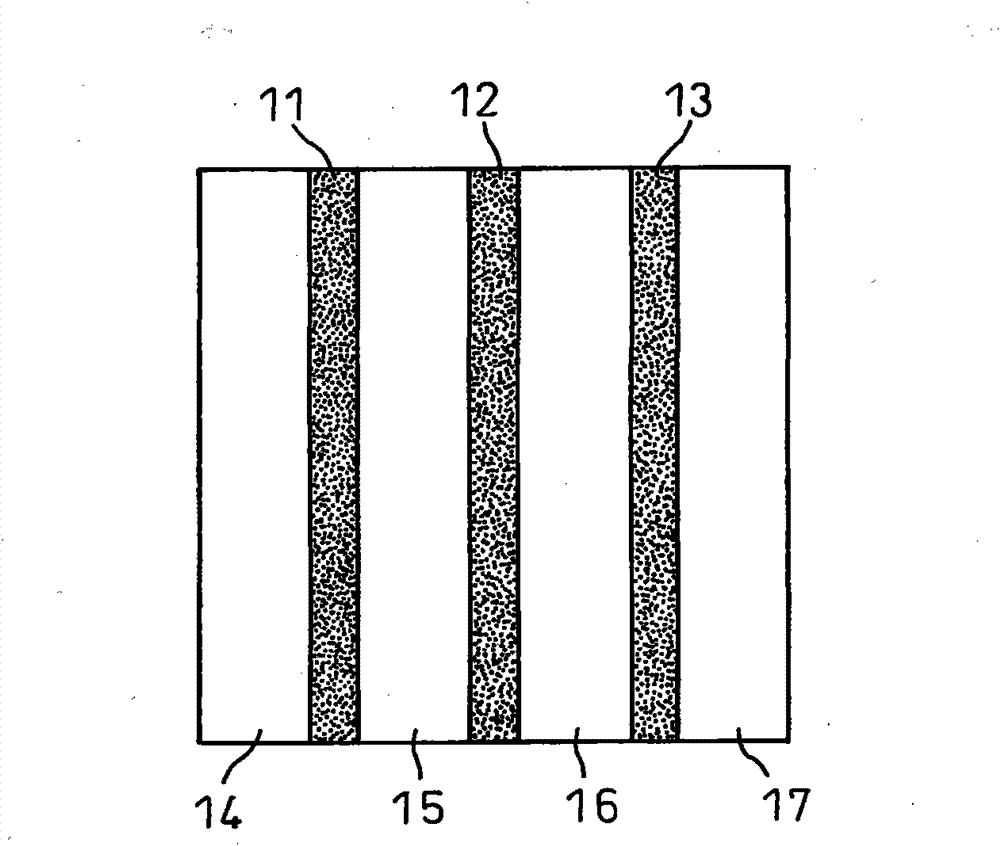

[0070] In Example 1, it was the same as Example 1 except that the fluorine process was not performed. In the obtained fabric, the calendered surface had good glossiness and was soft to the touch (grade 3). In addition, in accordance with JIS-Z8741, the specular reflectance at a measurement angle of 60 degrees and a measurement angle of 20 degrees was measured using a gloss meter "PG-1M" manufactured by Nippon Kogyo Co., Ltd., and the specular reflectance at 60 degrees and the specular reflectance at 20 degrees were calculated. The difference ΔRR, the result is 8.40. The obtained fabric consisted only of organic fibers A having a single fiber diameter of 520 nm.

Embodiment 3

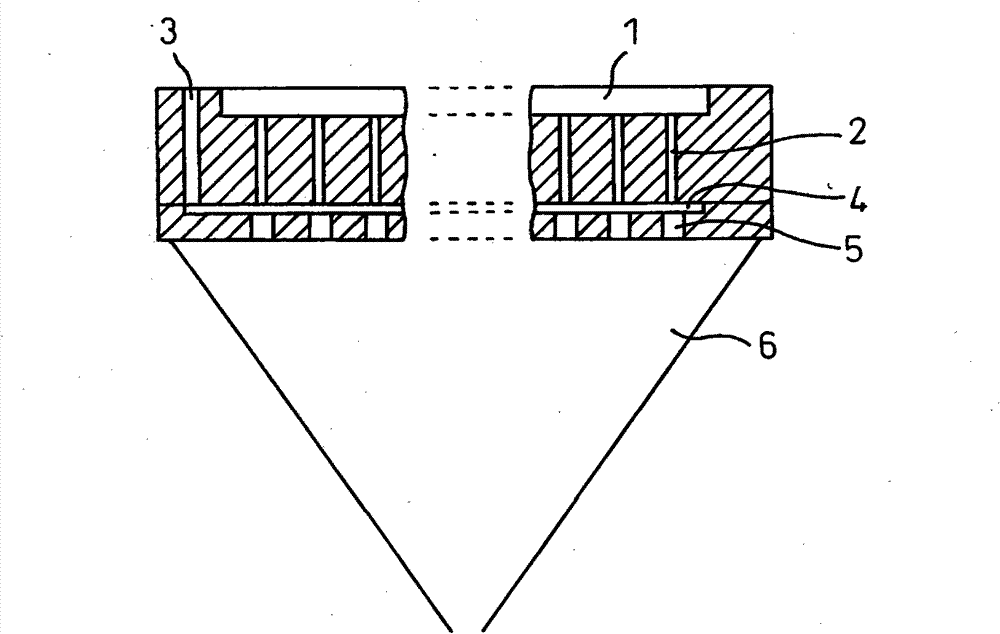

[0075] Polyethylene terephthalate was used as the island component, and 6 mol% of 5-sodium isophthalate and 6% by weight of polyethylene glycol with a number average molecular weight of 4000 were used as the sea component. Polyethylene terephthalate (dissolution speed ratio (sea / island)=230), with spinning temperature 280 ℃, spinning speed 1500m / min melt spinning goes out to sea: island=40:60, number of islands= 500 island-in-the-sea composite undrawn fibers were temporarily wound. The obtained unstretched yarn was subjected to roll drawing at a drawing temperature of 80° C. and a draw ratio of 2.5 times, and then heat-set at 150° C. and wound up. The obtained sea-island type composite drawn yarn was 56 dtex / 10fil, and the cross-section of the fiber was observed with a transmission electron microscope TEM. As a result, the shape of the islands was circular, and the diameter of the islands was 700 nm. The island-in-the-sea type composite drawn yarn 56dtex / 10fil (fiber for orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com