Purification treatment method and device of mixed and smelly rubber smoke exhaust gas

A technology of exhaust gas purification and treatment methods, which is applied in chemical instruments and methods, separation methods, climate sustainability, etc., and can solve problems such as non-exhaust gas purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

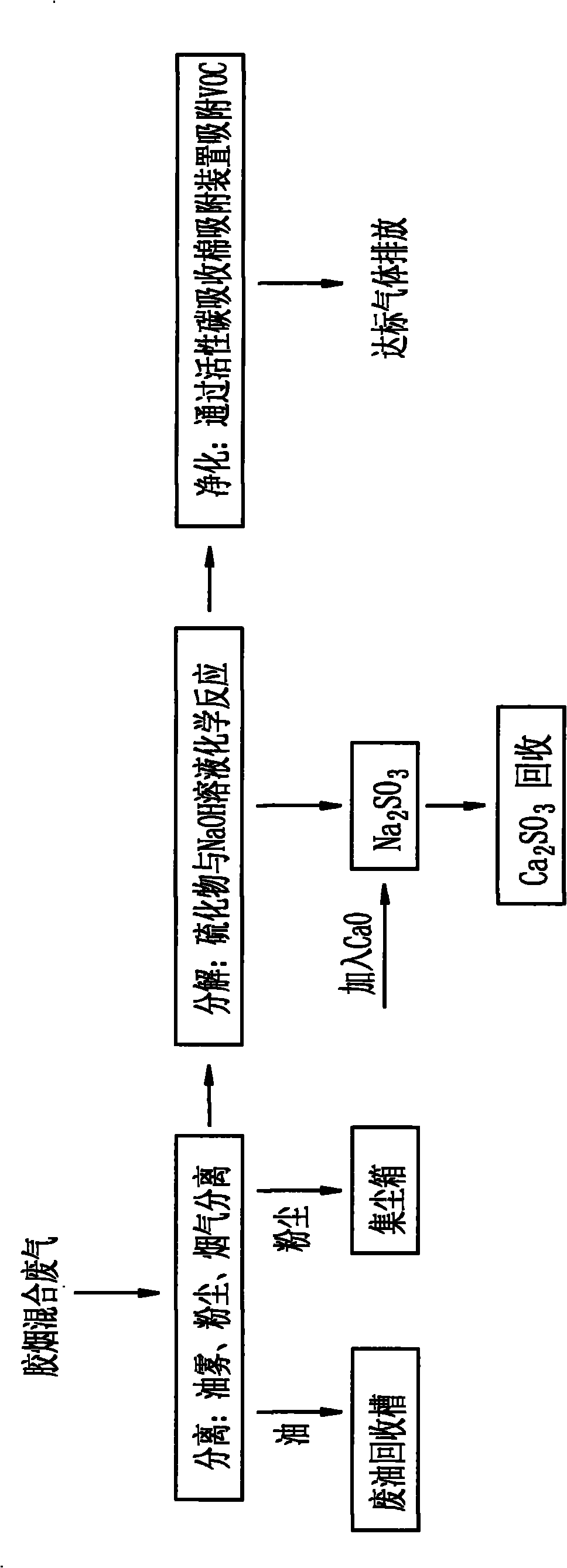

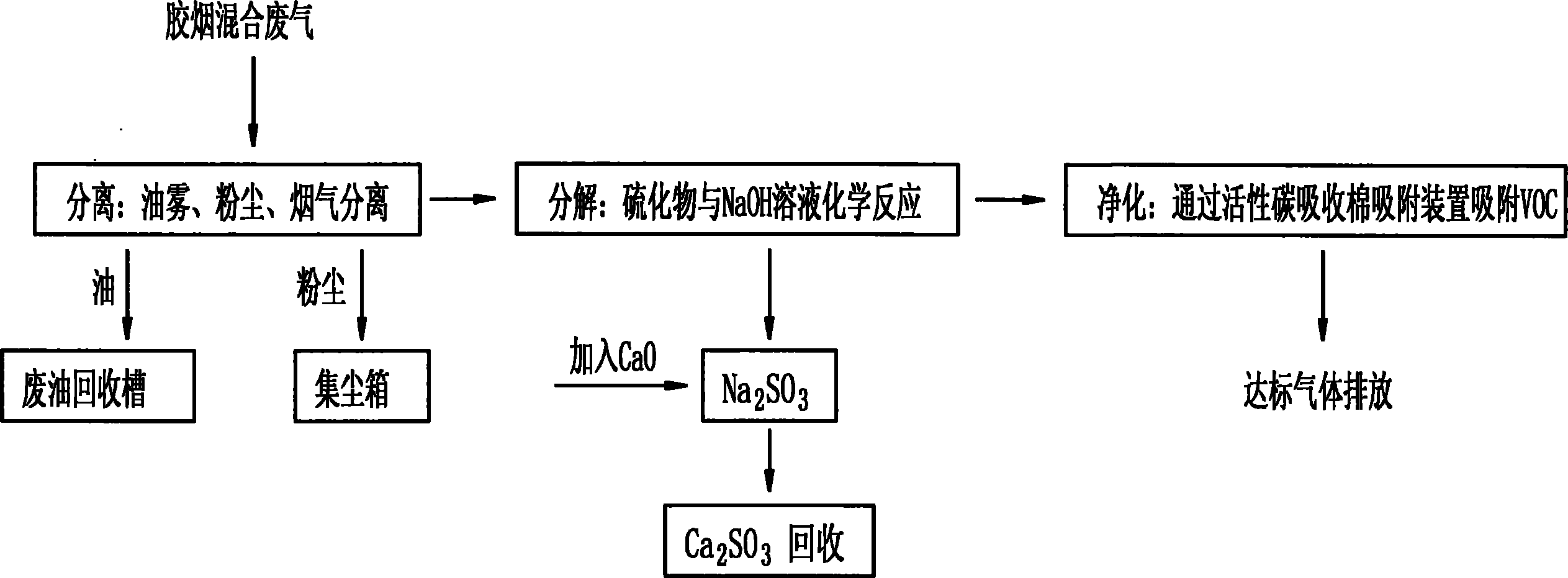

[0022] figure 1 The process flow chart of the purification treatment method of rubber fume mixed with peculiar smell waste gas of the present invention is given, and the waste gas of rubber fume collected on site is processed through three processes in sequence:

[0023] Separation: Pass the rubber smoke and dust mixed with peculiar smell exhaust gas into the separation box, spray the solution water containing NaOH in the reverse direction, and use self-circulation spray to make the rubber smoke oil float on the water surface, flow into the waste oil recovery tank together with the liquid water for recovery, and the dust is recovered by Gravity settles to the bottom of the sink for recycling to the dust bin.

[0024] Decomposition: After the separation, the residual harmful gas is passed into the decomposition box, and the mixed solution containing NaOH is continuously sprayed to decompose the sulfide mainly sulfur dioxide, and react to form sodium sulfite soluble in water. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com