Mold for wood painting and lacquer painting

A technology of woodware and lacquer painting, applied in the field of wooden embryo production technology, can solve the problems of unstable embryo quality, poor flame retardant effect, heavy weight of finished products, etc., and achieve good product quality stability, avoid cracking and falling off, and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

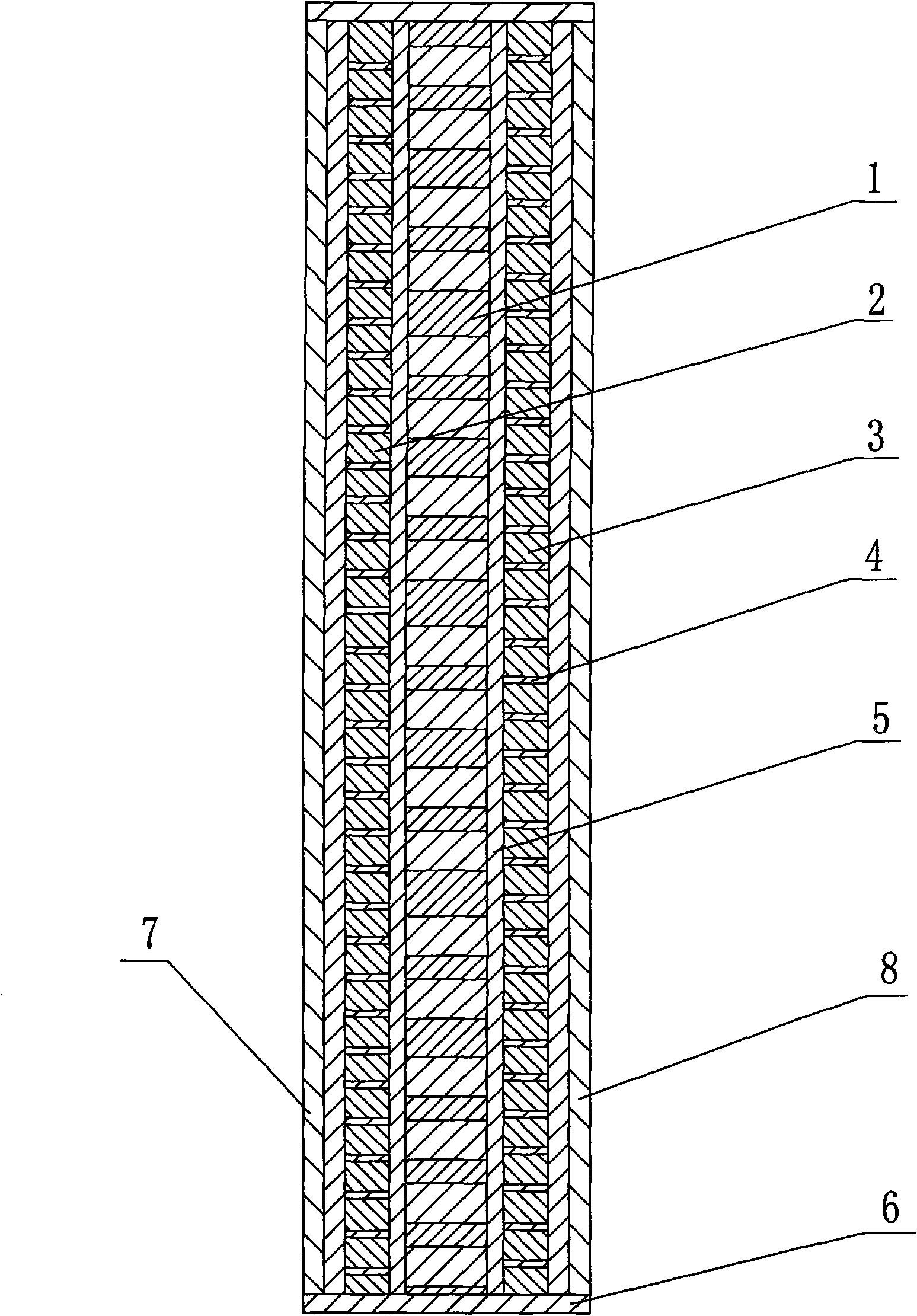

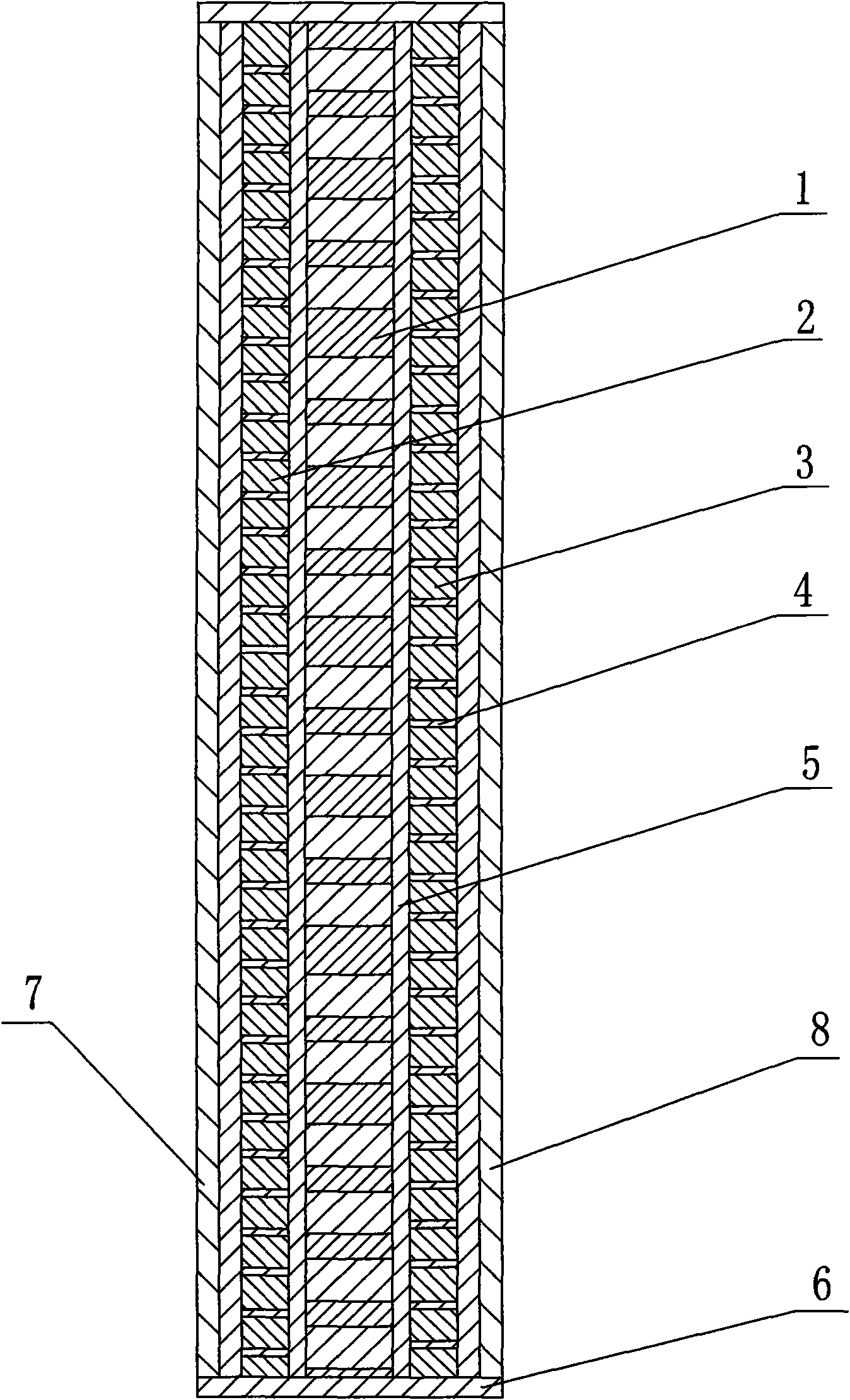

[0008] Such as figure 1 As shown, the present invention arranges yellow cardboard 2,3 respectively on the two sides of network skeleton 1, and through hole 4 is evenly distributed on described yellow cardboard 2,3 respectively, and network skeleton 1 and two yellow cardboard 2 , 3 are fixedly connected with each other by polyurethane foaming agent 5, and acrylic sheet wrapping 6 is arranged on the outer circumference perpendicular to the large surface of the embryo, and acrylic sheet wrapping 6 is also connected by polyurethane foaming agent 5 and mesh skeleton 1 and Two pieces of yellow cardboard 2, 3 are connected to each other.

[0009] Paint layers 7 and 8 are respectively arranged on the outer surfaces of the two yellow board papers 2 and 3 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap