Antigravity dilute-phase pneumatic conveying device for fluid

A pneumatic conveying and anti-gravity technology, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of cultivated land occupation, low yield, drop in the bucket, etc., and achieve the effect of cost saving, simple structure and powerful function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

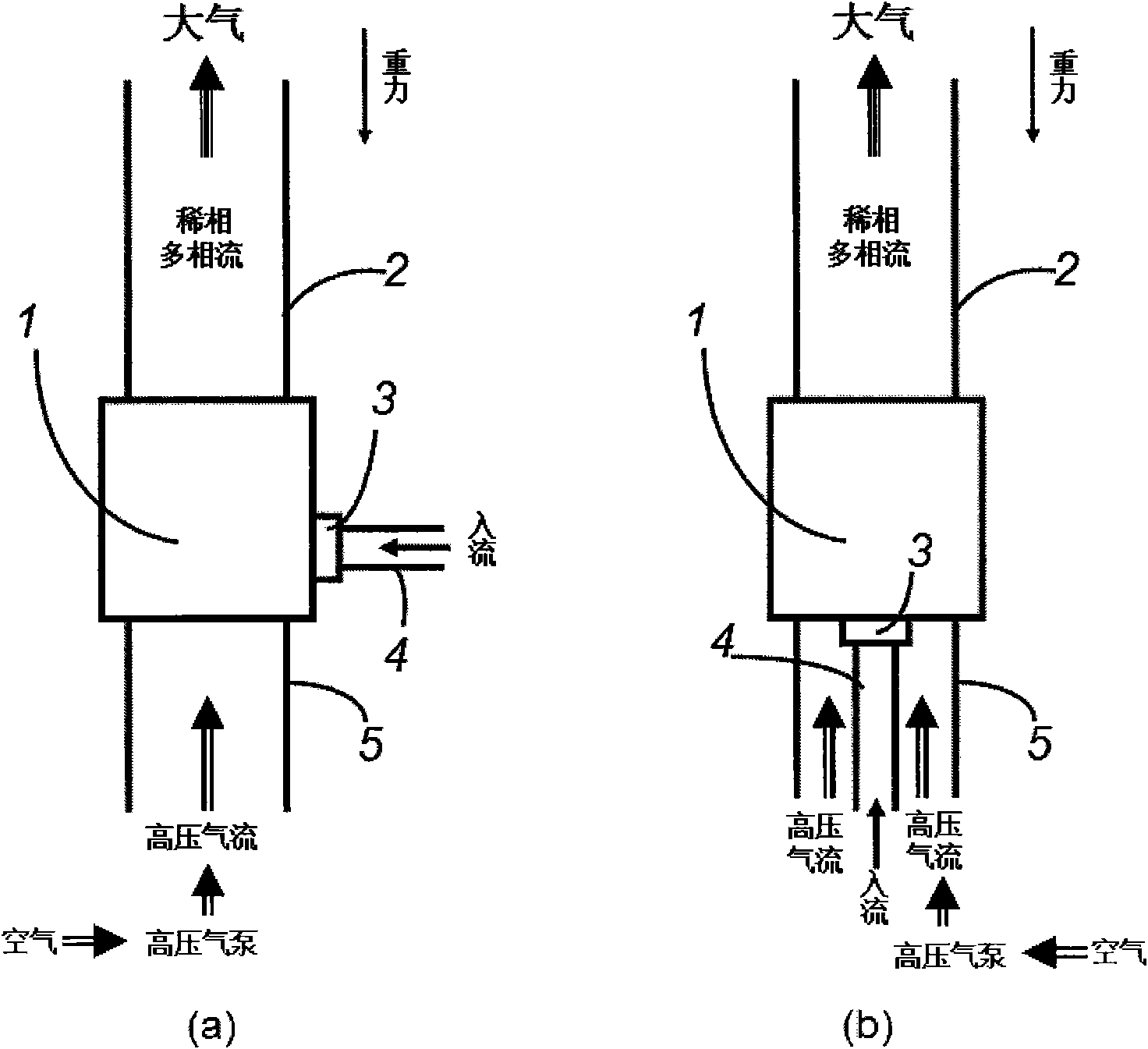

[0039] Embodiment one: see figure 1 , the anti-gravity dilute phase pneumatic conveying device of the fluid, the atomization cavity 1, the buoyancy tube 2, the atomizer 3, the inflow tube 4 and the gas inlet tube 5. The atomization chamber 1 is connected with the buoyancy tube 2 , the atomizer 3 and the gas inlet tube 5 , and the inlet tube 4 is connected with the atomizer 3 . The water flow in the inflow pipe 4 is sprayed into the atomization chamber 1 through the atomizer 3, and mixed with the high-pressure airflow entering the atomization chamber 1 from the air inlet pipe 5 to form a high-pressure steam and mist flow, and then under the action of the pressure difference , the buoyancy tube 2 transports the high-pressure steam and mist to the anti-gravity direction, and finally enters the atmosphere at the outlet of the buoyancy tube to achieve the purpose of changing the atmospheric humidity.

Embodiment 2

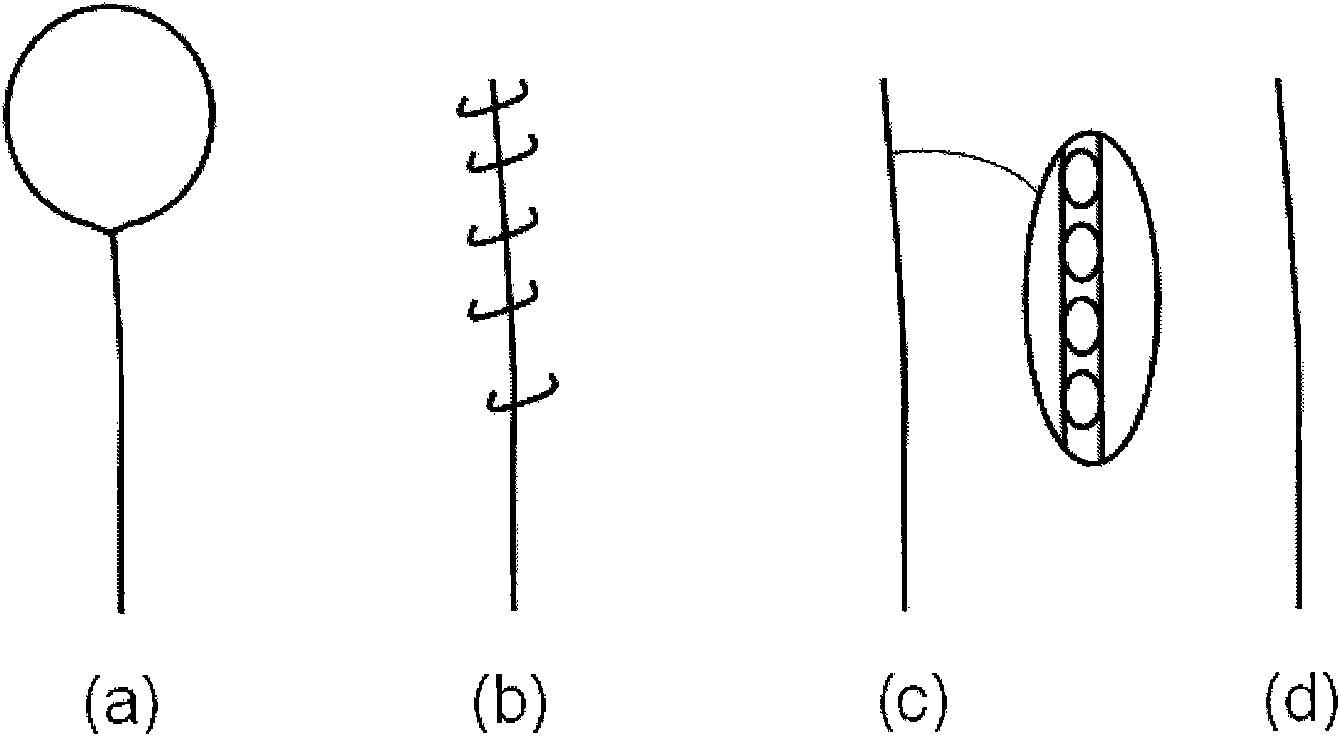

[0040] Embodiment two: see figure 1 and figure 2 , the principle of this embodiment is the same as that of Embodiment 1, and the special features are: the buoyancy tube is a pipe fitting made of light material, and there is a light balloon traction tube (a), or a kite traction tube (b), or a light air bubble film tube ( c), or homogeneous material pipe (d), the high-pressure airflow provided by external power sends atomized water or powder particles into the atmosphere.

Embodiment 3

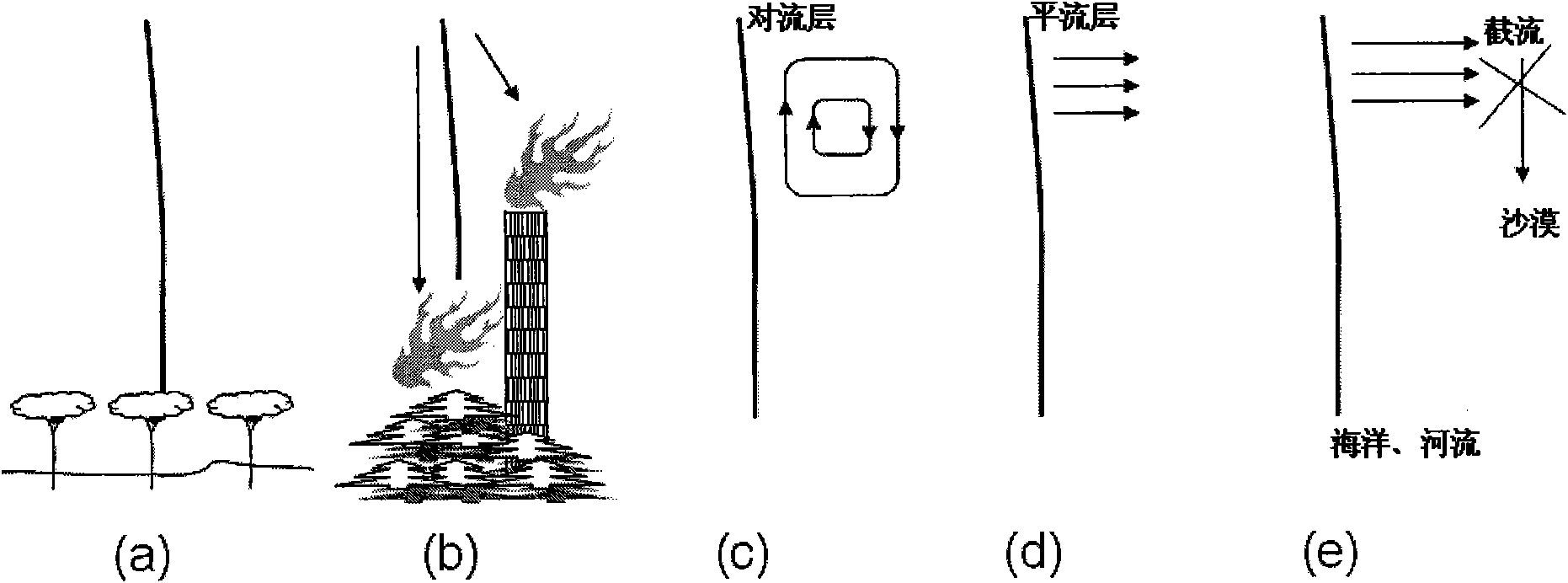

[0041] Embodiment three: see figure 1 and image 3 (a), the principle of this embodiment is the same as that of Embodiment 1, and the special feature is: the purpose of applying this device here is to irrigate a large area, so that irrigation no longer only depends on the time-consuming and labor-intensive ground engineering on the ground, and does not Complex topography needs to be considered and areas far from water sources can be irrigated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com