Light trap adopted epitaxial material structure of ultrafine divergent angle high-power semiconductor laser

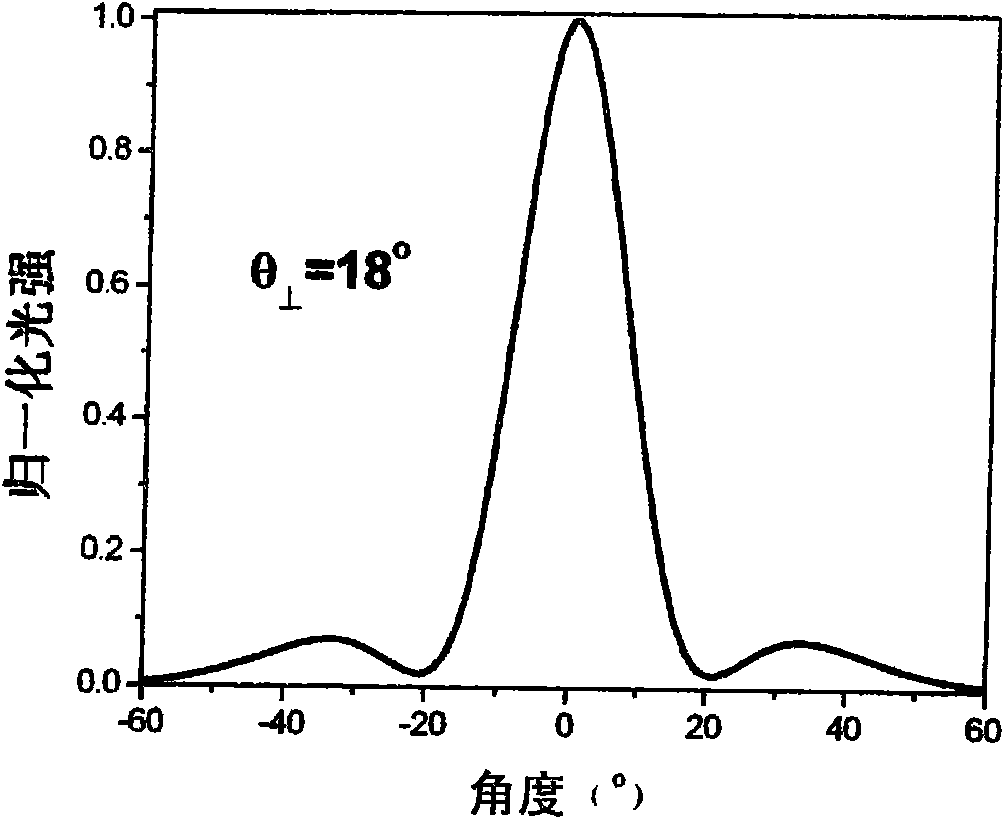

A technology of epitaxial materials and optical traps, applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of poor device spot symmetry, unfavorable laser beam efficient coupling, etc., and achieve the effect of reducing the vertical divergence angle of the far field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

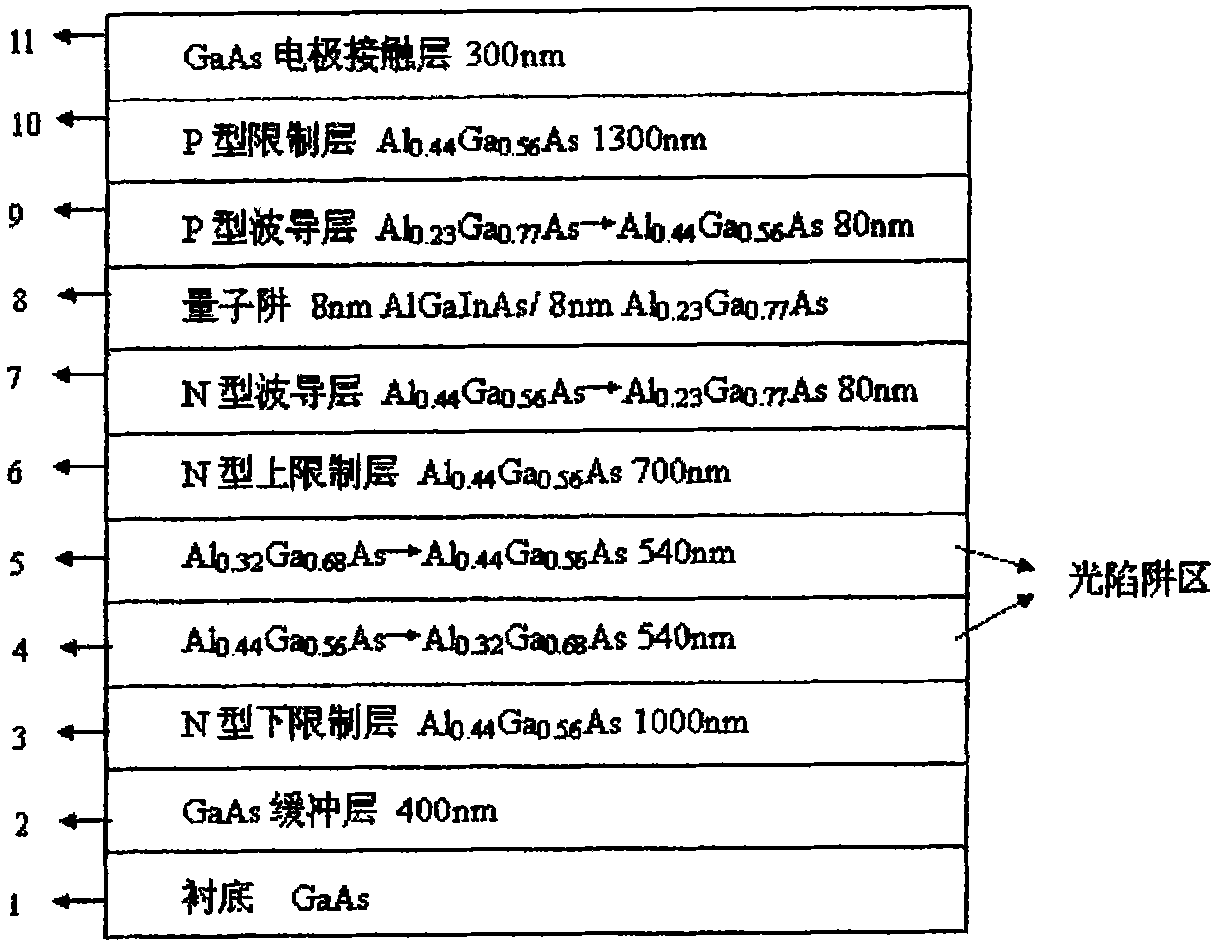

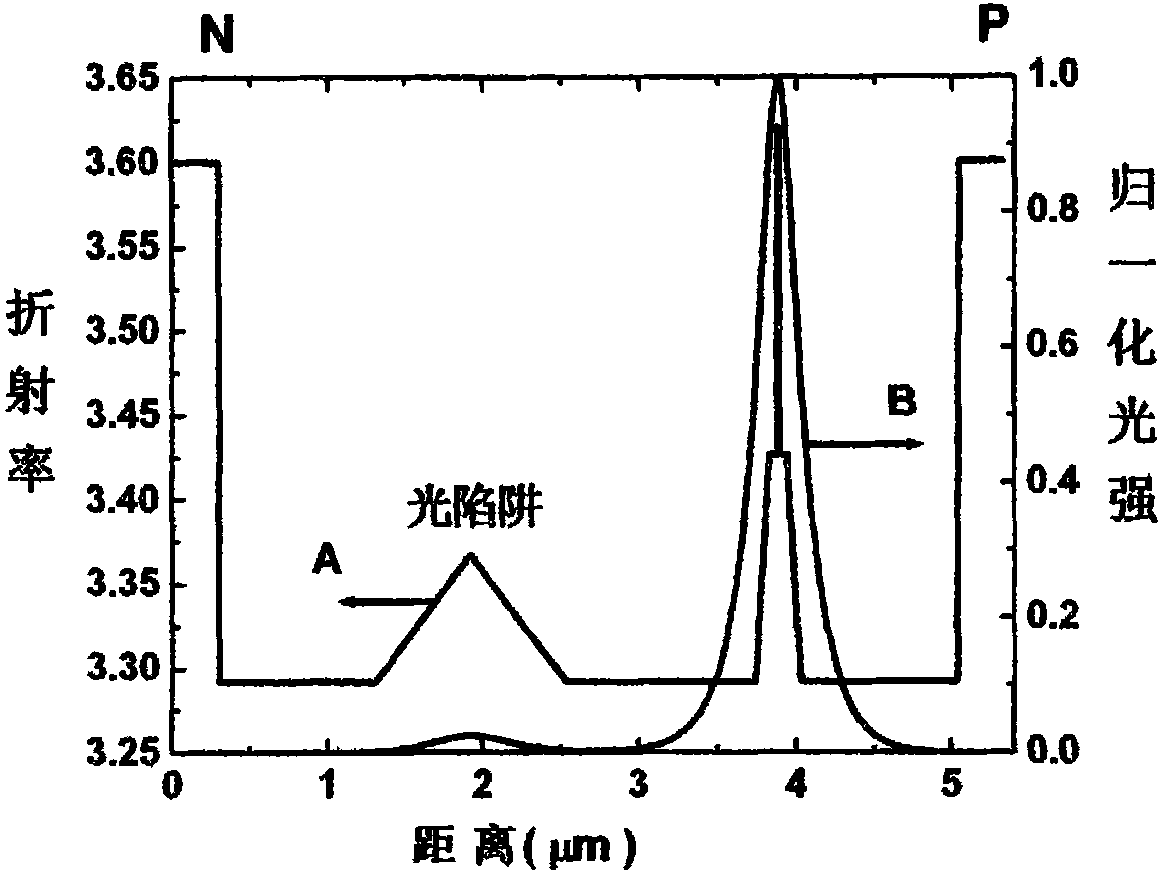

[0034] see figure 1 As shown, the present invention adopts an optical trap ultra-small divergence angle high-power semiconductor laser epitaxial material structure, which is characterized in that it includes:

[0035] A substrate 1, the GaAs substrate 1 is used to carry out the epitaxial growth of each layer of the laser material thereon, the substrate is an N-type GaAs material of the (100) plane, and the Si doping concentration is 1-2×10 18 cm -3 , with a thickness of 320-380 μm;

[0036] A buffer layer 2, which is made on the GaAs substrate 1, is N-GaAs material, and the Si doping concentration is 1-2×10 18 cm -3 , the thickness is 300-600nm;

[0037] An N-type lower confinement layer 3, the N-type lower confinement layer 3 is made on the buffer layer 2, and the N-type lower confinement layer 3 is N-Al 0.44 Ga0.56 As material, Si doping concentration is 1-2×10 18 cm -3 , the thickness is 1000-1200nm;

[0038] A graded optical trap layer 4, which is fabricated on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com