Single screw compressor

A single-screw compressor and screw technology, which is applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of single-screw compressor efficiency reduction, screw rotor and gate gap, etc., to reduce losses and reduce friction Loss, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

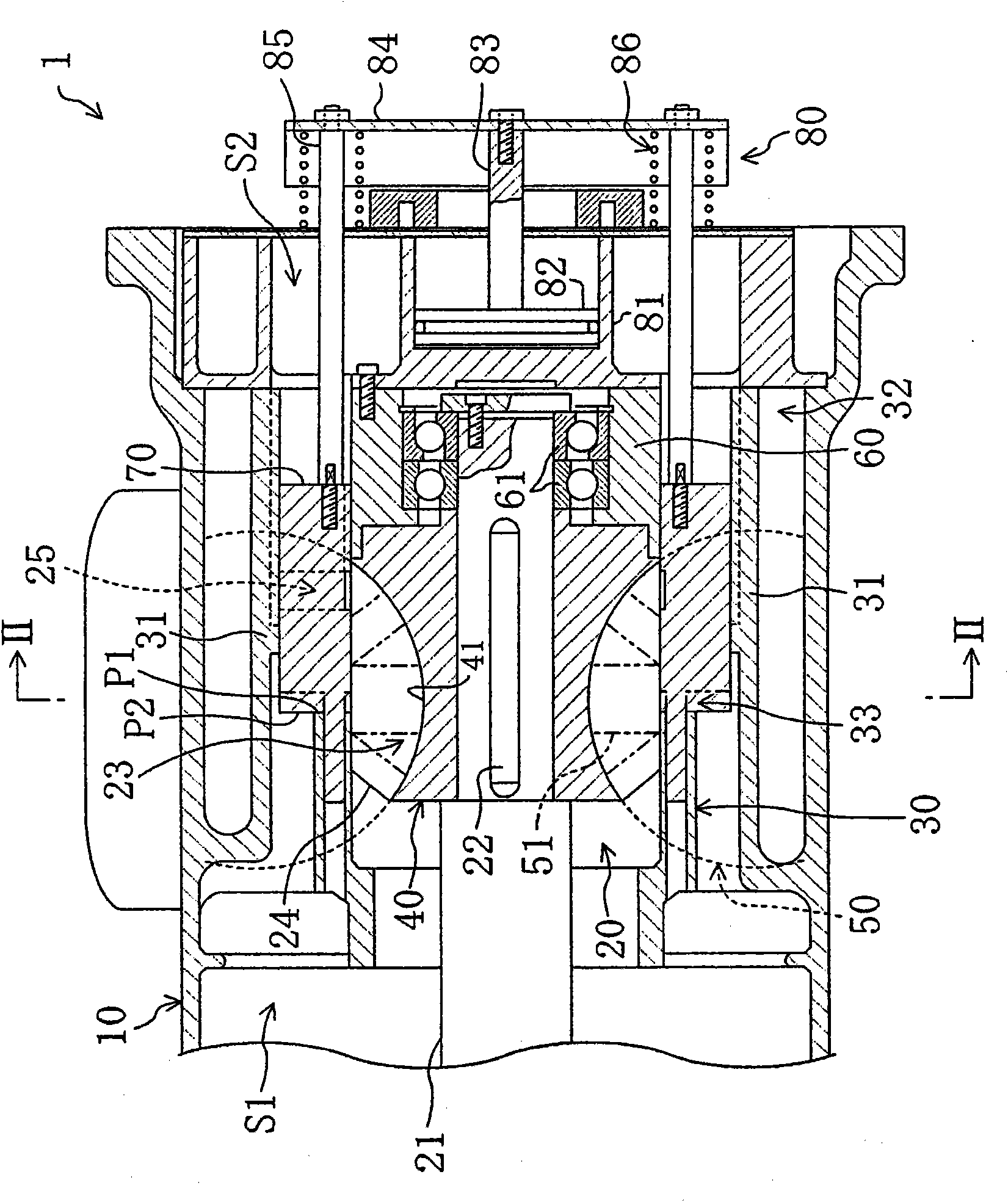

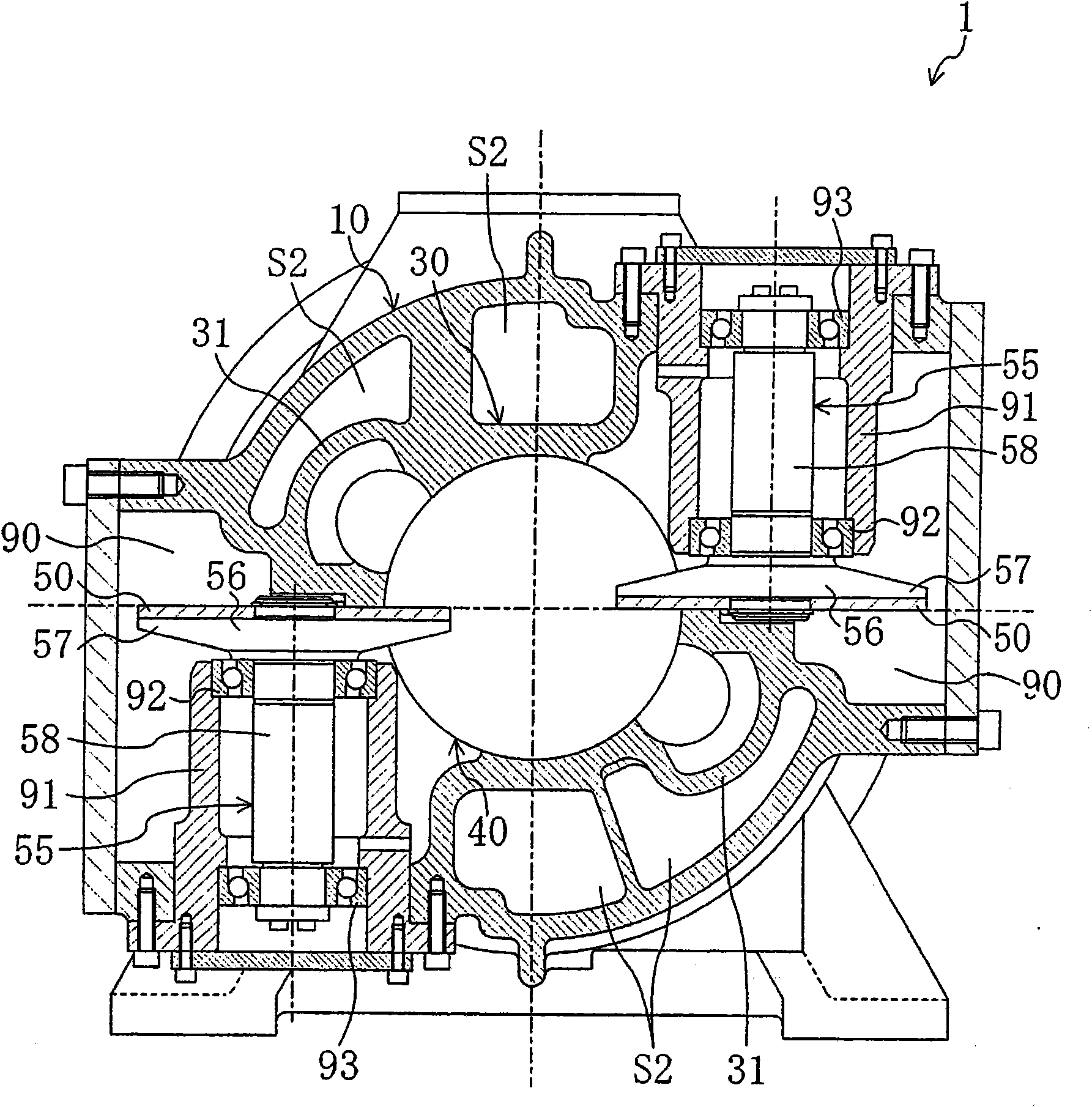

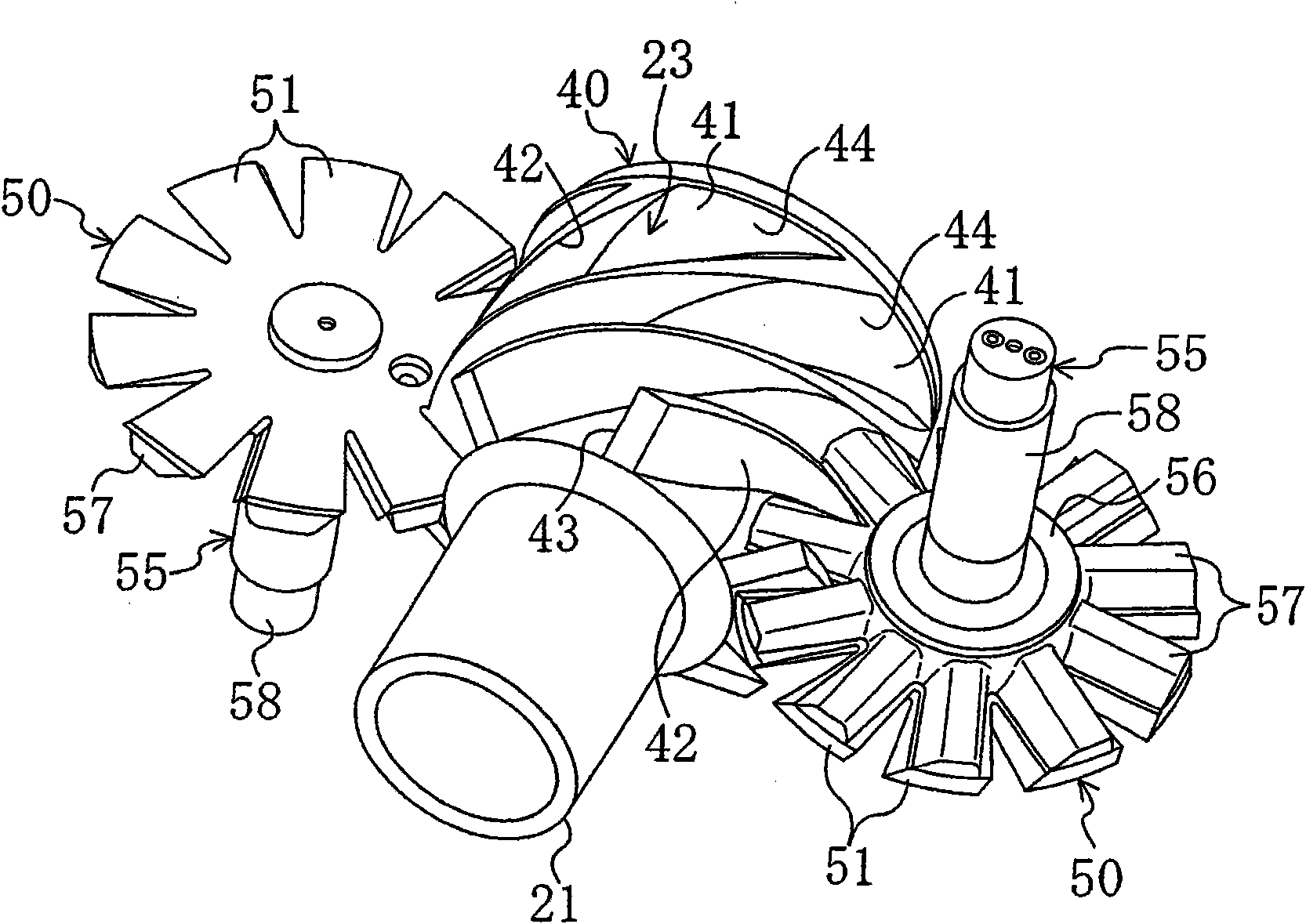

[0042] Hereinafter, embodiments of the present invention will be described in detail based on the drawings.

[0043] The single-screw compressor (1) (hereinafter, simply referred to as a screw compressor) of the present embodiment is installed in a refrigerant circuit that performs a refrigeration cycle to compress a refrigerant.

[0044] Such as figure 1 , figure 2 As shown, the screw compressor (1) constitutes a semi-hermetic type. In this screw compressor (1), a compression mechanism (20) and an electric motor for driving it are housed in one casing (10). The compression mechanism (20) is connected with the motor through a drive shaft (21). In Figure (1), the motor is omitted. In addition, the casing (10) is divided into a low-pressure space (S1) that introduces low-pressure gas refrigerant from the evaporator of the refrigerant circuit and introduces the low-pressure gas into the compression space (20), and discharges the inflow from the compression mechanism (20). T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com