Photovoltaic cells having metal wrap through and improved passivation

A photovoltaic and passivation layer technology, applied in the direction of photovoltaic power generation, circuits, electrical components, etc., can solve the problems of MWT solar energy efficiency limitations, achieve the effect of reducing recombination current and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

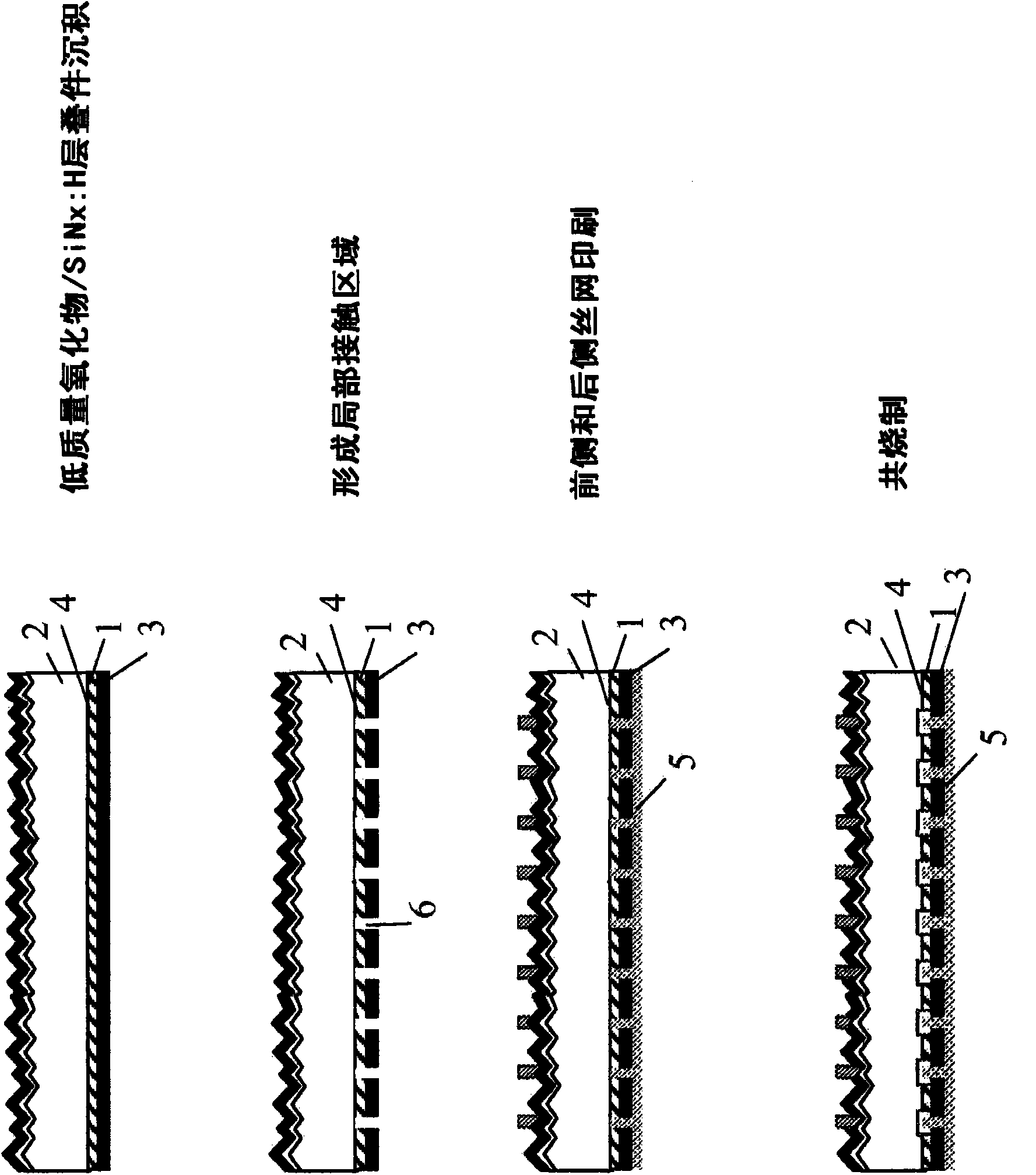

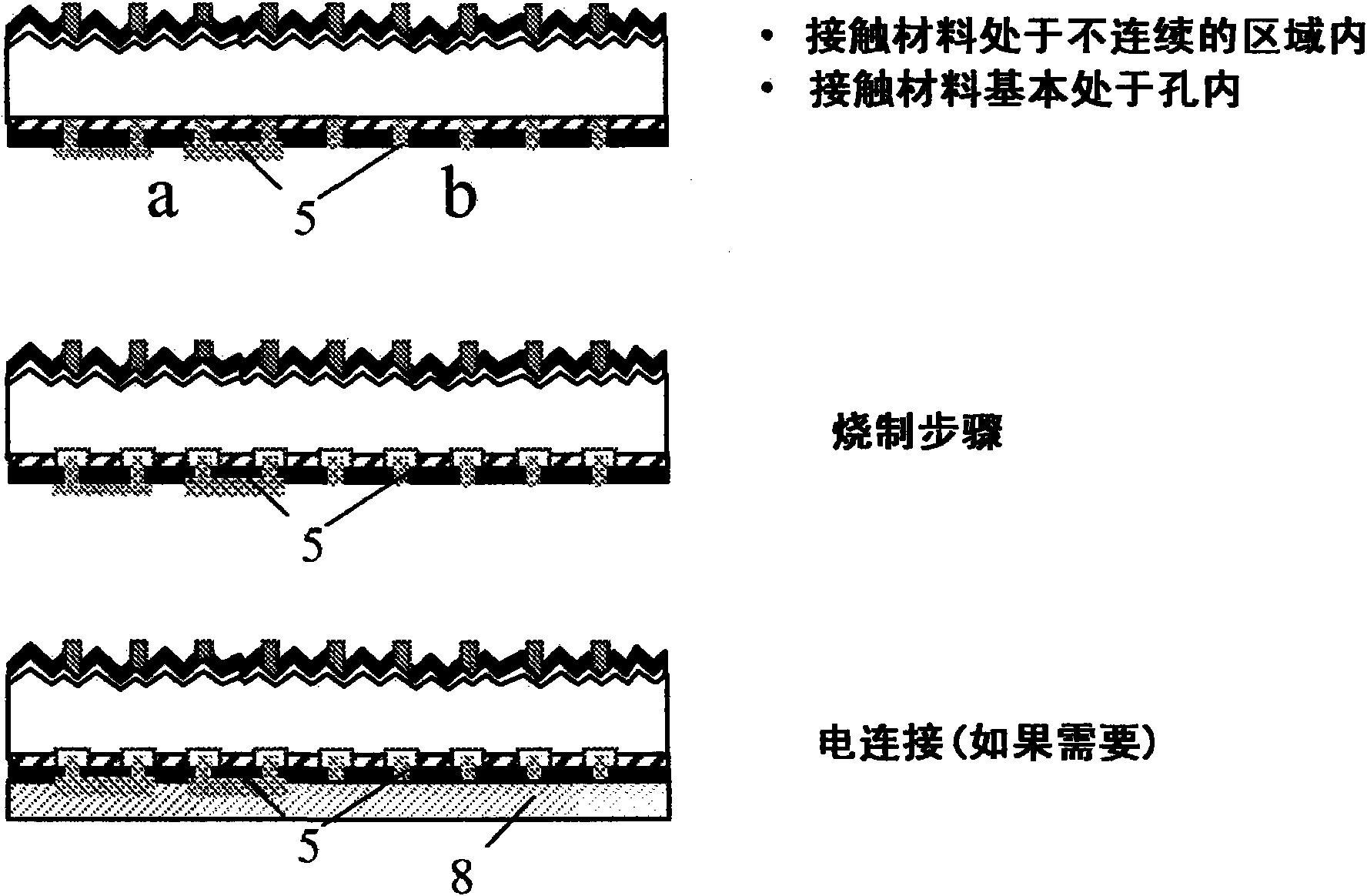

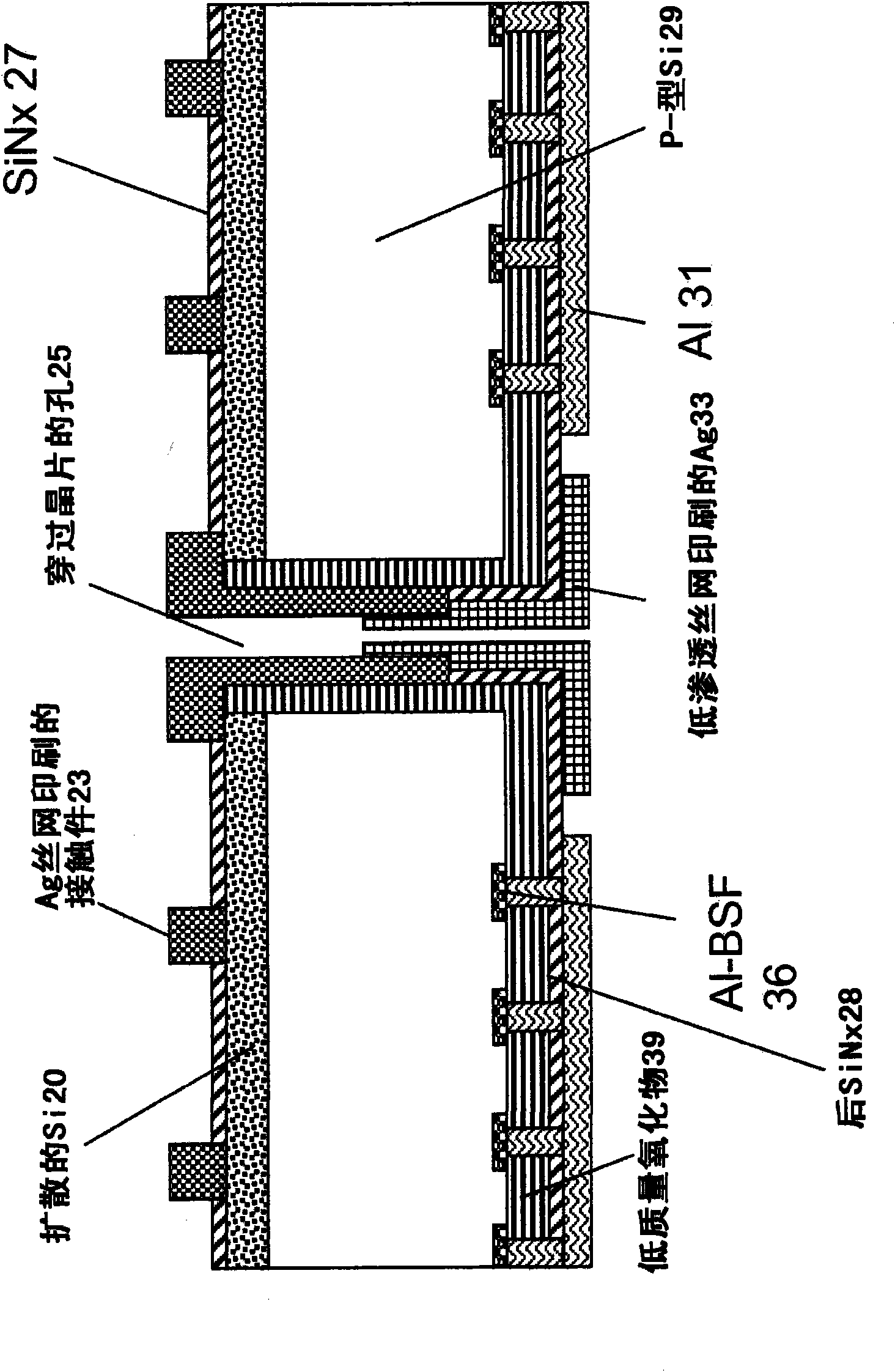

[0026] How to implement the present invention will be described below with respect to specific embodiments with reference to certain drawings, but the present invention is not limited thereto. The drawings described are only schematic and not restrictive. In the drawings, the size of some of the elements is exaggerated and not drawn on scale for illustrative purposes.

[0027] In addition, in the description as well as in the claims, the terms "first", "second" and "third" etc. are used to distinguish similar elements and do not necessarily describe a sequence or chronological order. It is to be understood that the terms are used interchangeably under appropriate circumstances and that the embodiments of the invention described herein are capable of operation in other sequences than described or illustrated herein.

[0028] In addition, in the specification and claims, the terms "top", "bottom", "above", "below" and the like are used for description and not necessarily for de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com