Artificial femoral prosthesis

A femoral prosthesis and artificial technology, applied in the field of hip joint prosthesis, can solve the problems of unequal length of the two lower limbs, aggravate the stress shielding of the stem, and achieve the effects of preventing osteolysis, preventing excessive subsidence, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

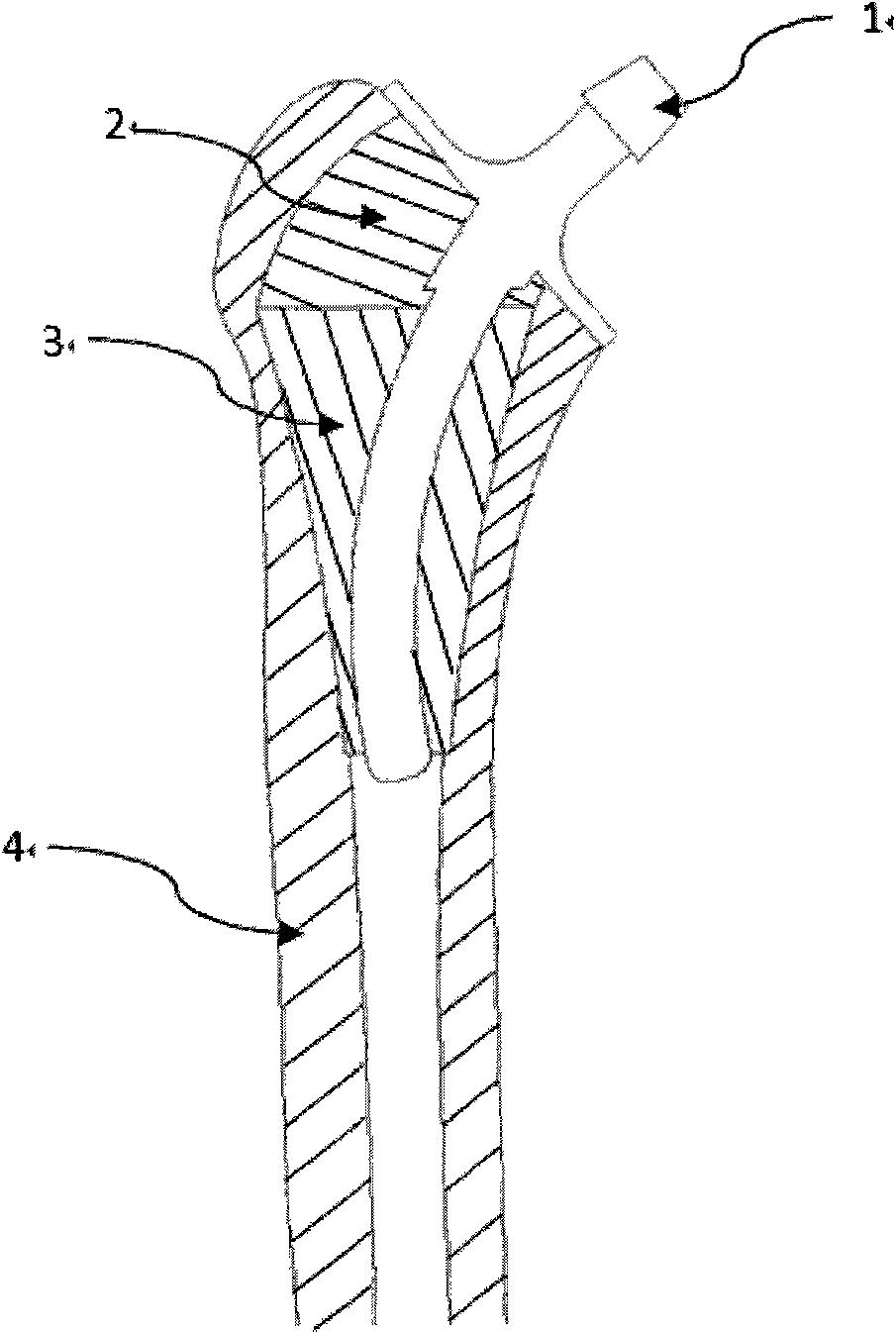

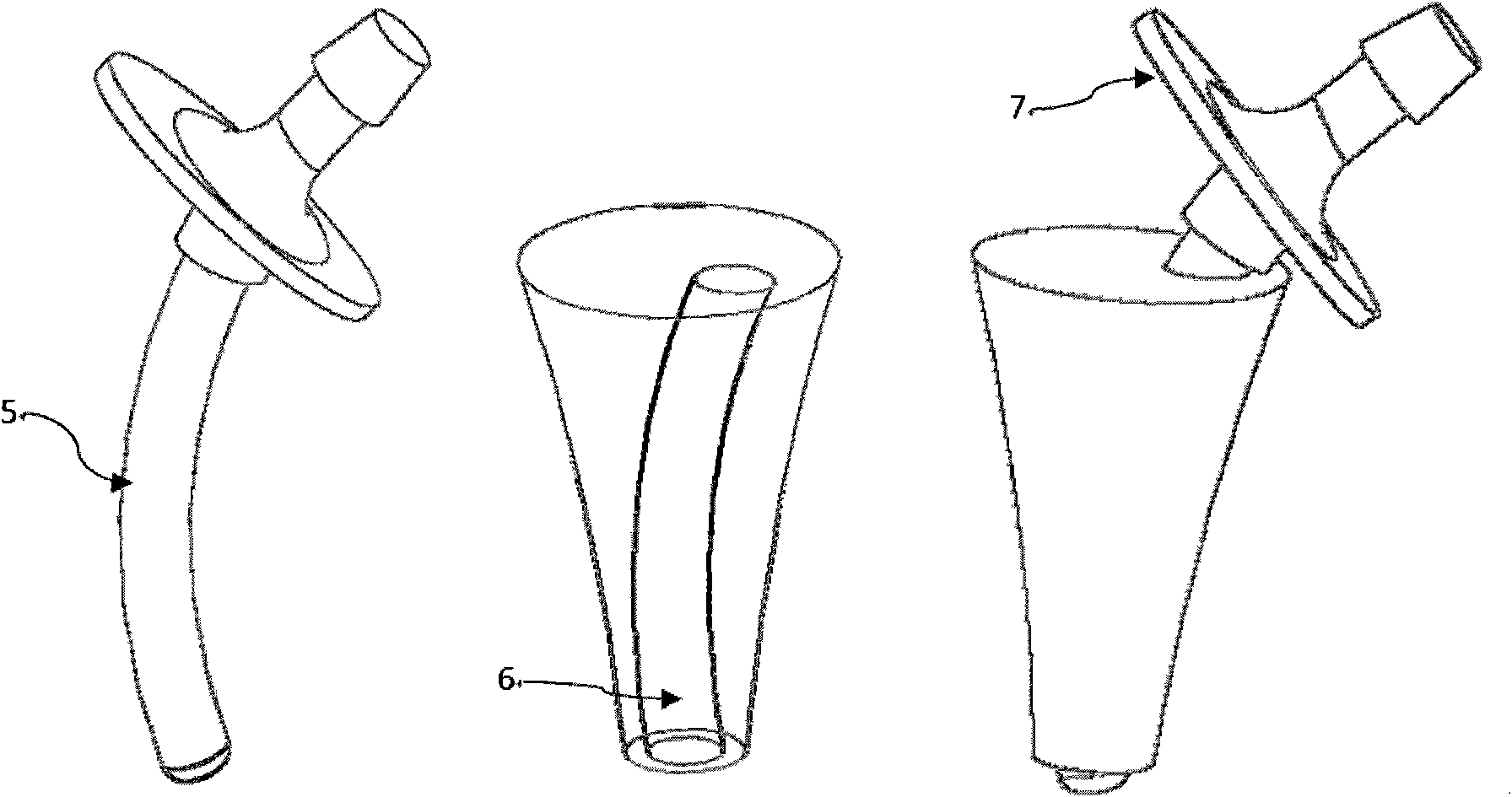

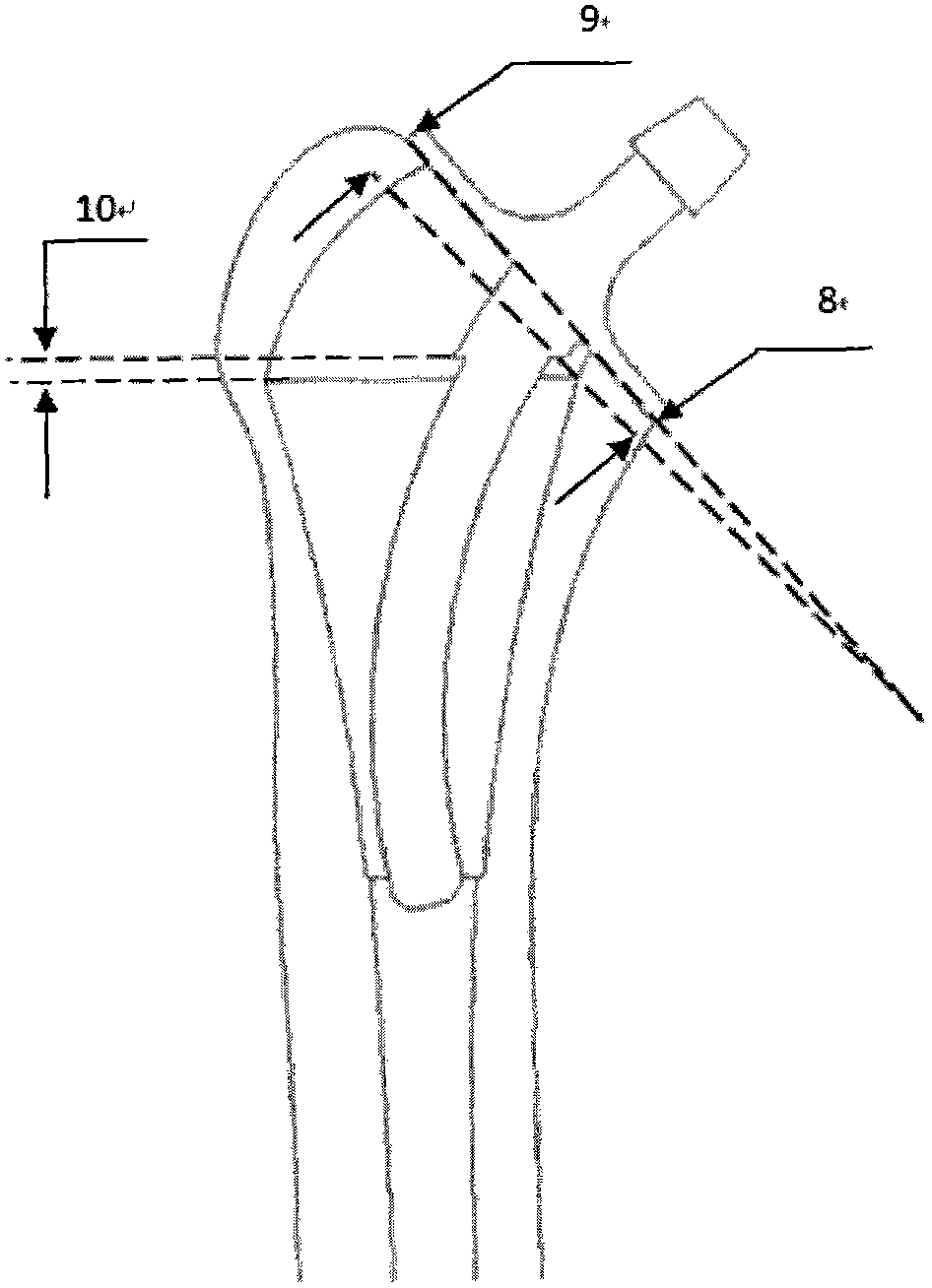

[0011] The operation process of the artificial femoral prosthesis of the present invention is similar to the existing hip joint operation process, in which the skin is cut and the femoral head is sawed off, and the marrow is reamed. Implant the outer sleeve (3) into the medullary cavity of the femur (4), then fill the position of the bone graft block (2) with autologous bone or allogeneic bone or bone cement or other materials, and place the femoral stem (1) Insert the bone graft block (2) and the outer sleeve (3), and the treatment is completed.

[0012] When the artificial hip joint prosthesis is stressed, the stress is transmitted from the collar of the femoral stem (7) to the proximal end of the femur (4) and the bone graft block (2), and then to the distal end of the femur. That is to say, the stress transfer mode of the prosthesis and the femur in parallel connection in the prior art is transformed into the mode of serially bearing the stress transmitted from the collar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com