Blanking adjustable discharging hopper device and concrete batch plant applying same

A technology of unloading hopper and blanking, which is applied in the direction of unloading device, valve device, mechanical equipment, etc., can solve the problems of not meeting the unloading demand, affecting the unloading time, concrete accumulation, etc., to achieve simple design and improve unloading. Speed, life-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

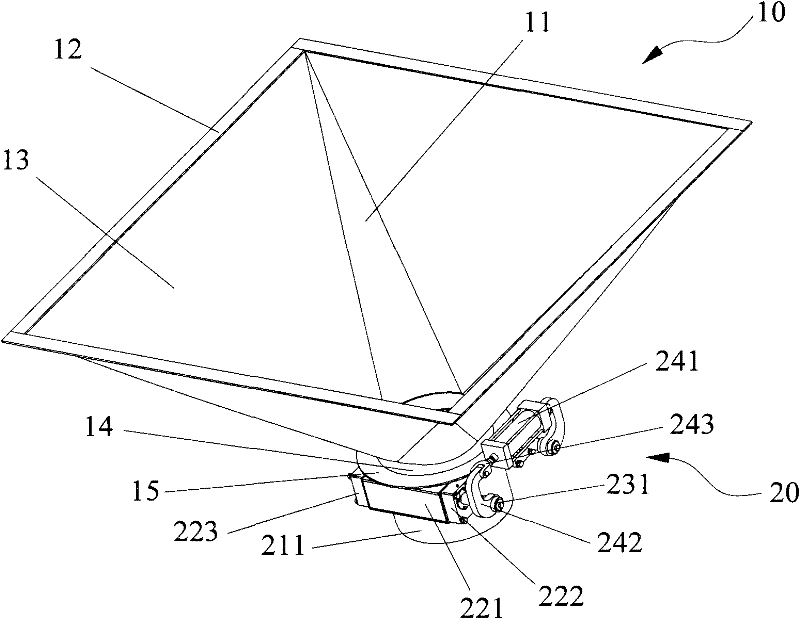

[0032] see figure 1 , the discharge hopper device of the present invention comprises a discharge hopper assembly 10 and a discharge valve assembly 20, the lower end of the discharge hopper assembly has a discharge hopper flange 15, and the upper end of the discharge valve assembly 20 is provided with a valve flange 215, through these two methods Lan, the discharge valve assembly 20 is connected to the bottom of the discharge hopper assembly 10.

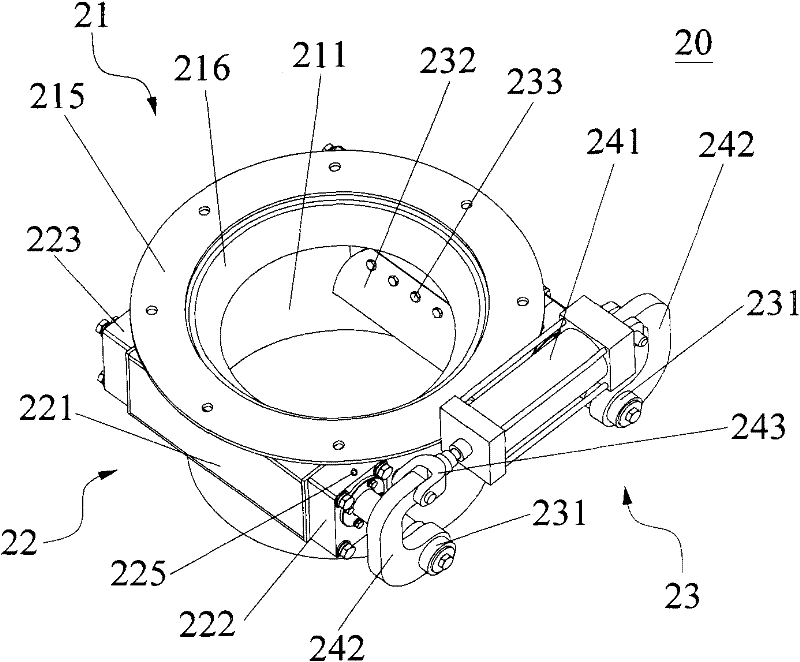

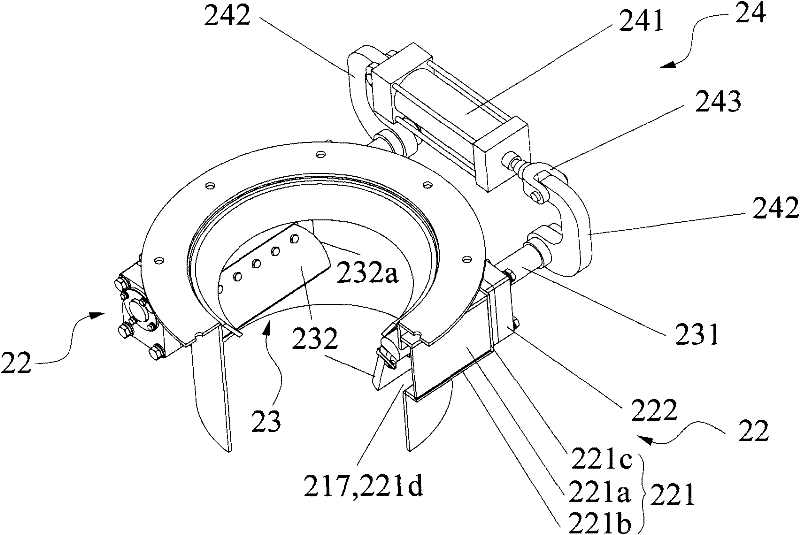

[0033] see you again figure 2 and image 3 , the discharge valve assembly 20 includes a cylindrical valve body part 21, a valve part 23 and a drive part 24, a seat body part 22 can be further set on the cylindrical valve body part 21, and the valve part 23 is installed in the seat body part 22 , and ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com