Method for pressurizing and molding composite part by using thermal expansion of silicone rubber

A composite material and pressure forming technology, which is applied in the field of silicone rubber thermal expansion and pressure forming composite parts, can solve the problems of poor practicability and complicated calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

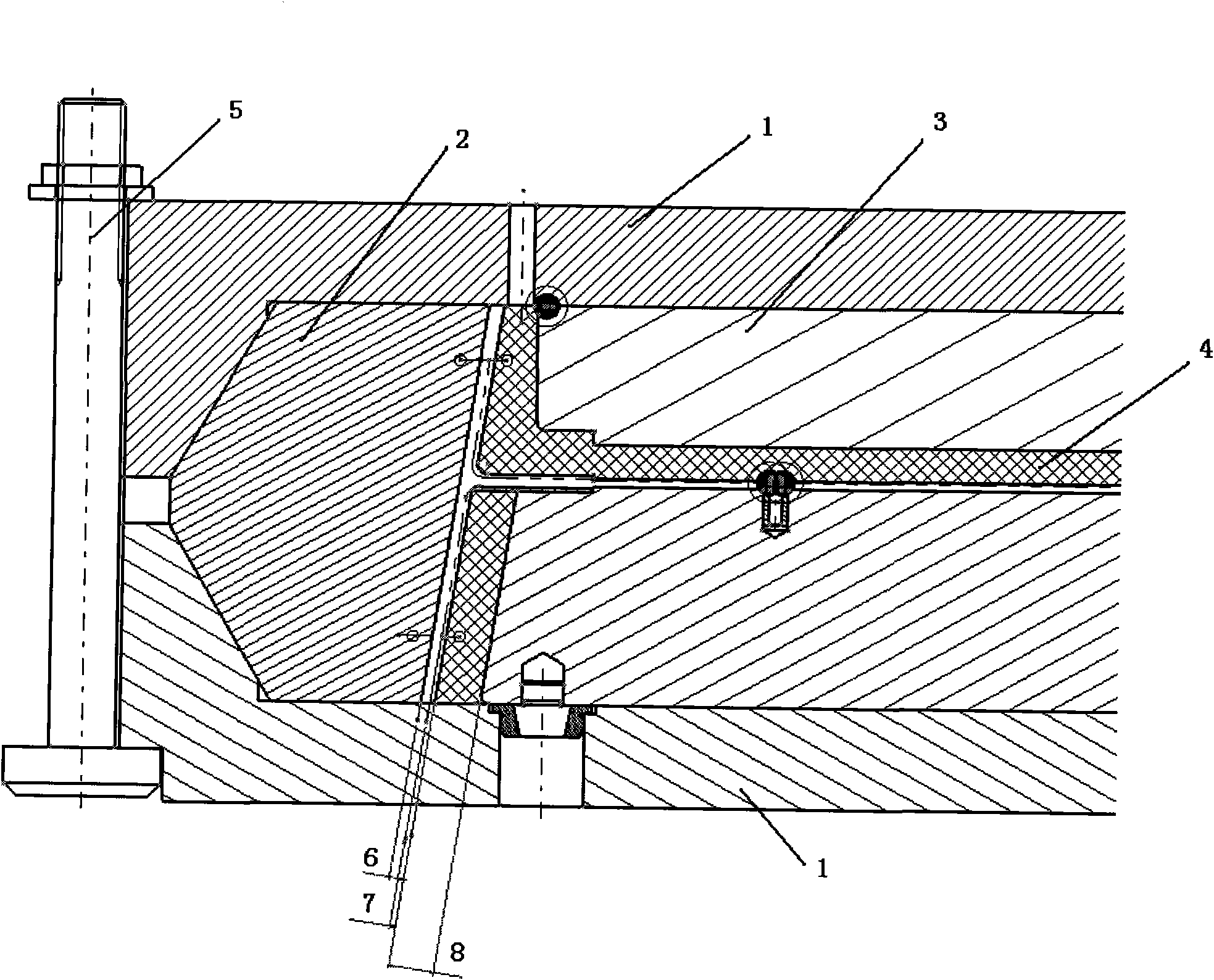

[0026] The technical solution of the present invention will be described in further detail below in conjunction with accompanying drawings and examples of implementation:

[0027] See attached figure 1 As shown, the product is a high-precision laminate of composite materials, and the airfoil and web parts are carbon fiber prepregs of different thicknesses. The requirements for shape accuracy and porosity are relatively high, the molding and curing pressure is 0.5Mpa, and the molding and curing temperature is 180°C. The mold material is Q235 low-carbon steel, the forming mold 1 adopts the product shape positioning, and the inside is a combination of mold loose block 2, metal core mold 3 and silicon rubber core mold 4, which are fixed and fastened with bolts 5. By raising the temperature, the molding pressure is provided from the inside by the thermal expansion of the silicone rubber.

[0028] Its specific process steps are:

[0029] 1. Lay the prepreg of the composite materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com