Preparation method of hollow round tube pyramid type completely composite material lattice laminboard

A composite material and pyramid technology, applied in the field of preparation of pyramid-shaped lattice sandwich panels, can solve problems such as poor mechanical properties, and achieve the effect of large moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

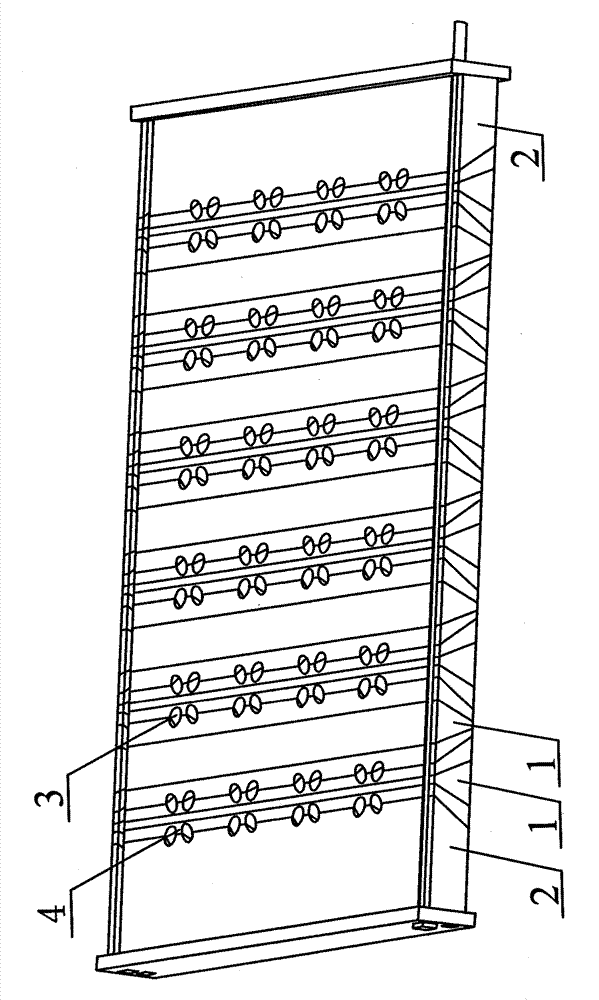

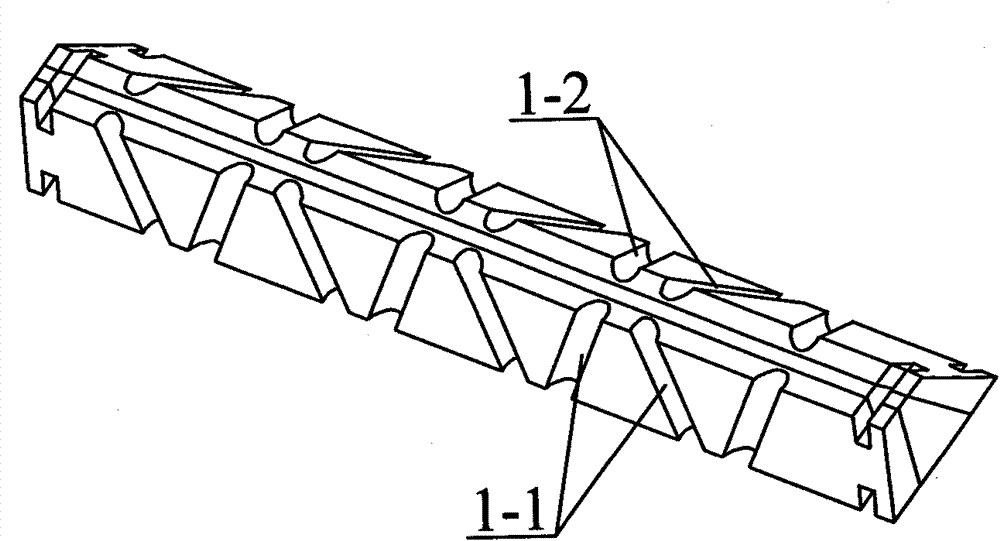

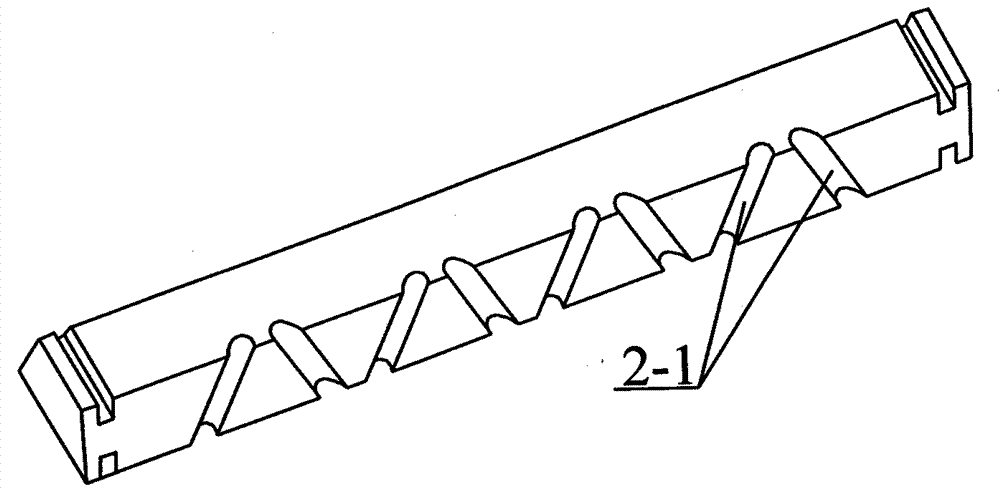

[0015] Specific implementation mode one: combine figure 1 Describe this embodiment, the preparation method of the hollow circular tube pyramid type all-composite lattice sandwich panel of this embodiment is completed by the following steps: Step 1: prepare rigid mold; rigid mold is made of a plurality of monomers 1 and two side plates 2, the cross-sectional shape of each monomer 1 is trapezoidal, and the cross-sectional shape of each side plate 2 is a right-angled trapezoidal shape; on a slope of each monomer 1, a plurality of pairs of the first through the slope width direction are processed. Semicircular through holes 1-1, each pair of first semicircular through holes 1-1 are arranged in a figure-eight shape, and each pair of first semicircular through holes 1-1 on the other slope of each monomer 1 A plurality of pairs of second semicircular through-holes 1-2 penetrating along the width direction of the slope are processed at the corresponding positions, and each pair of sec...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination figure 1 To illustrate this embodiment, in Step 1 of this embodiment, the thermal expansion mandrel 5 is made of silicone rubber or polymethacrylimide foam. Other compositions are the same as in Embodiment 1.

specific Embodiment approach 3

[0026] Embodiment 3: In step 7 of this embodiment, the curing temperature is 120° C., the curing time is 2 hours, the longitudinal pressing pressure is 1 MPa, and the transverse pressure on the fiber column 6 is 1 MPa. Pressure can be applied to both the panel and the fiber column, so that the fiber column is not easy to split when loaded, which can improve the mechanical properties of this type of sandwich structure and increase the structural strength by at least 2 times. Other method steps are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com