Method for biologically purifying municipal sewage and recovering resources

A technology for biological purification and resource recovery, applied in chemical instruments and methods, biological sludge treatment, multi-stage water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

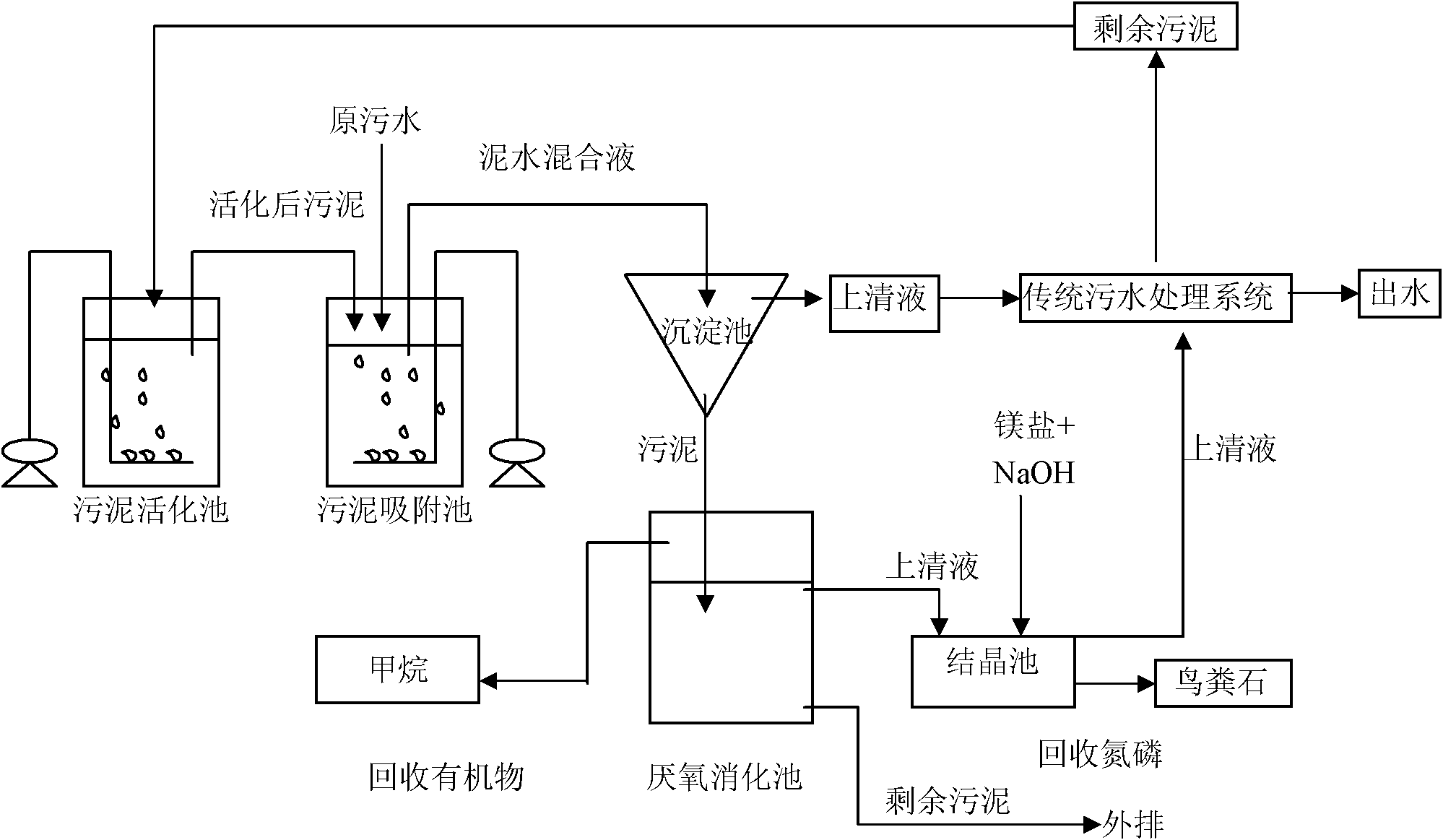

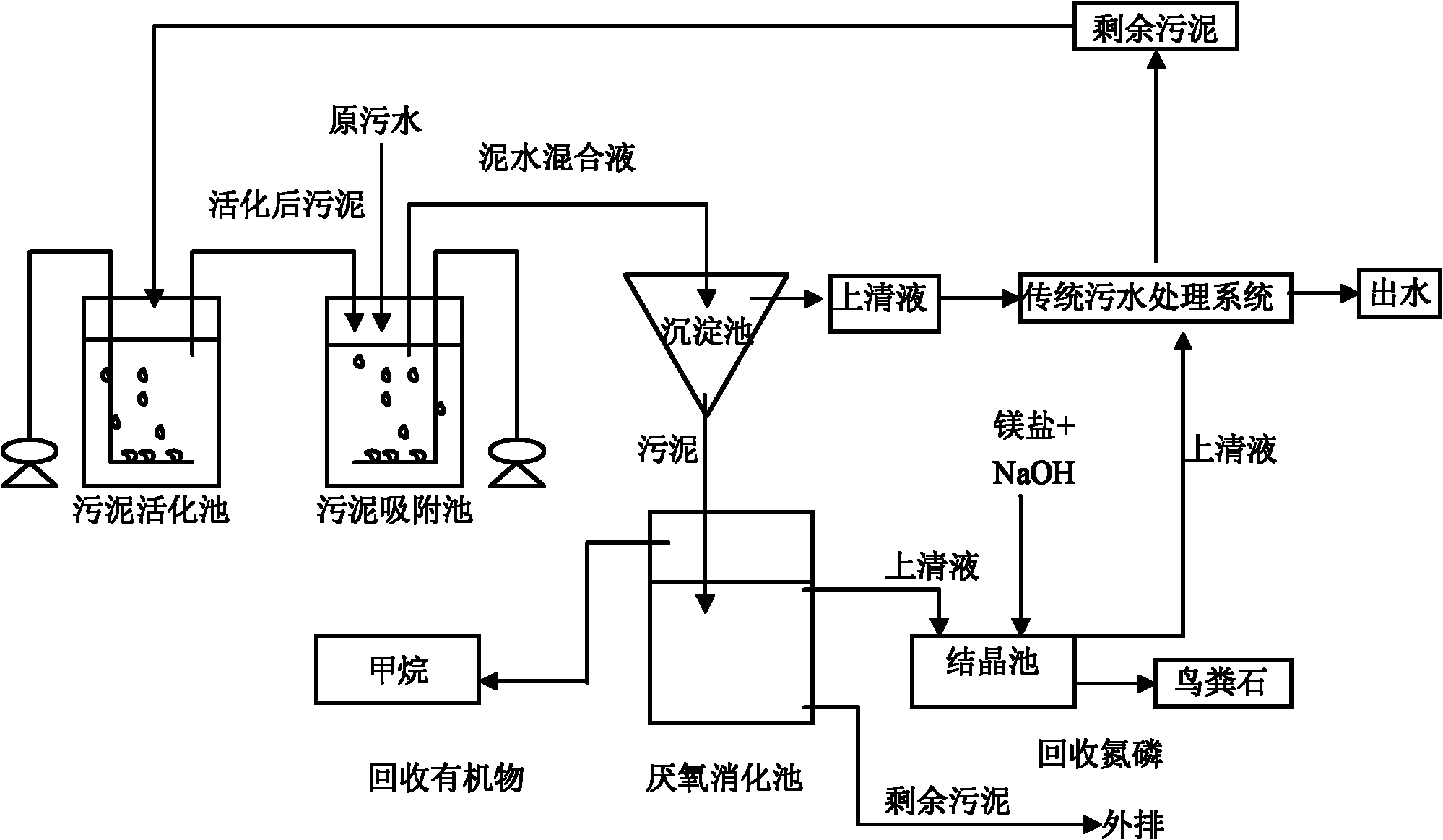

Method used

Image

Examples

Embodiment 1

[0025] 1) Discharge the remaining pre-dewatered concentrated sludge (SS: 4000mg / L) produced by the urban sewage treatment plant into the sludge activation tank for aerobic aeration for 30 minutes to keep D0 at 2mg / L to activate the sludge;

[0026] 2) Then the activated sludge and urban sewage (COD 260-500mg / L, SS 220-350mg / L, ammonia nitrogen 24-40mg / L, soluble phosphate 2-5mg / L) are mixed according to the volume ratio of the raw sewage Mixed at a ratio of 1:3, discharged into the sludge adsorption tank for aerobic aeration for 30 minutes, so that the sludge and sewage are fully mixed, and the D0 is controlled at 1mg / L;

[0027] 3) Enter the mud-water mixture after step 2) aerobic aeration into the sedimentation tank, settle for 1.5 hours, and the supernatant after precipitation (COD about 160-240mg / L, SS 100-130mg / L, ammonia nitrogen 10- 20mg / L and phosphorus 1-2mg / L) into the traditional sewage purification system, the pollutants in the sewage are oxidized and decomposed, a...

Embodiment 2

[0034] 1) Discharge the remaining pre-dewatered concentrated sludge (SS: 4000mg / L) produced by the urban sewage treatment plant into the sludge activation tank for aerobic aeration for 30 minutes, keeping D0 at 4mg / L, and activate the sludge;

[0035] 2) Then the activated sludge and urban sewage (COD 260-500mg / L, SS 220-350mg / L, ammonia nitrogen 24-40mg / L, soluble phosphate 2-5mg / L) are mixed according to the volume ratio of the raw sewage Mixed at a ratio of 1:1, discharged into the sludge adsorption tank for aerobic aeration for 30 minutes, so that the sludge and sewage are fully mixed, and the D0 is controlled at 2mg / L;

[0036]3) Enter the mud-water mixture after step 2) aerobic aeration into the sedimentation tank, settle for 2 hours, and the supernatant after precipitation (COD about 160-240mg / L, SS 100-130mg / L, ammonia nitrogen 10-20mg / L and phosphorus 1-2mg / L) into the traditional sewage purification system, the pollutants in the sewage are oxidized and decomposed, a...

Embodiment 3

[0043] 1) Discharge the remaining pre-dewatered concentrated sludge (SS: 4000mg / L) produced by the urban sewage treatment plant into the sludge activation tank for aerobic aeration for 30 minutes to keep D0 at 3mg / L to activate the sludge;

[0044] 2) Then the activated sludge and urban sewage (COD 260-500mg / L, SS 220-350mg / L, ammonia nitrogen 24-40mg / L, soluble phosphate 2-5mg / L) are mixed according to the volume ratio of the raw sewage Mixed at a ratio of 1:2, discharged into the sludge adsorption tank for aerobic aeration for 30 minutes, so that the sludge and sewage are fully mixed, and the D0 is controlled at 1.5mg / L;

[0045] 3) Enter the mud-water mixture after step 2) aerobic aeration into the sedimentation tank, settle for 2 hours, and the supernatant after precipitation (COD about 160-240mg / L, SS 100-130mg / L, ammonia nitrogen 10-20mg / L and phosphorus 1-2mg / L) into the traditional sewage purification system, the pollutants in the sewage are oxidized and decomposed, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com