Additive for strengthening tin oxidation volatilization in waste soldering tin and application thereof

A technology of oxidative volatilization and additives, which is applied in the field of tin oxidation and volatilization additives for strengthening waste solder and recycling tin, which can solve the problems of low added value of products, great harm to human body, low metal recovery rate, etc., and achieve easy mass production, Low cost, good application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

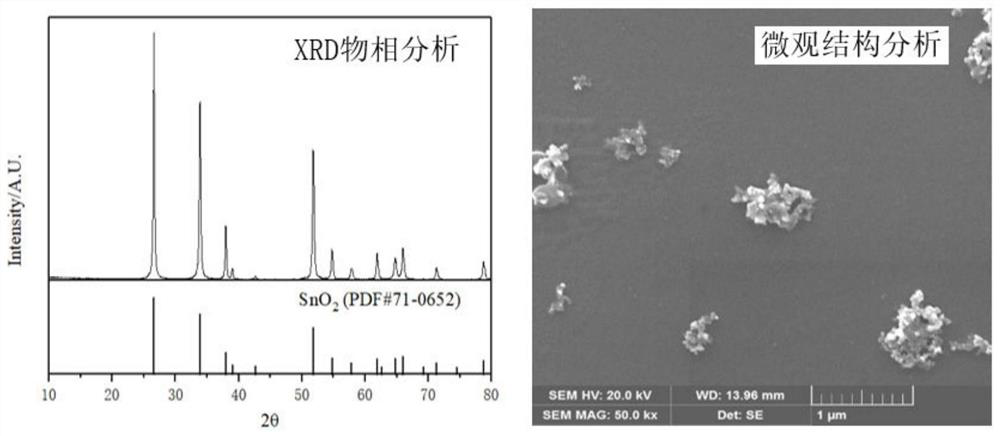

[0027] With the waste solder powder after mechanical crushing treatment as raw material (tin content 65.4%), raw material is mixed with the additive of 16% of waste solder quality (the component of weight portion of additive: 75 parts of inert aluminum oxide, 20 parts of silicon dioxide , 5 parts of stannous oxide) mixed evenly and then pressed into pellets, dried and then placed in a weakly oxidizing atmosphere at 925°C for 120 minutes of roasting; the weakly oxidizing atmosphere was composed of oxygen, carbon dioxide and nitrogen, of which The volume percentages are 1% and 10% respectively, and the balance gas is nitrogen; tin oxide is recovered, the tin recovery rate is 92.4%, and the purity of tin dioxide in the tin oxide is 96.7%. (obtain XRD phase analysis and microstructure analysis of tin oxide such as figure 1 Shown, grain size 56nm, theoretical purity 98.7%, product dispersion is good)

Embodiment 2

[0029] With the waste solder powder after mechanical crushing treatment as raw material (tin content 65.4%), raw material is mixed with the additive of 20% of waste solder quality (the component of weight portion of additive: 75 parts of inert aluminum oxide, 20 parts of silicon dioxide , 5 parts of stannous oxide) mixed evenly and then pressed into pellets, dried and then placed in a weakly oxidizing atmosphere at 925°C for 120 minutes of roasting; the weakly oxidizing atmosphere was composed of oxygen, carbon dioxide and nitrogen, of which The volume percentages are 1% and 10% respectively, and the balance gas is nitrogen; tin oxide is recovered, the tin recovery rate is 89.6%, and the purity of tin dioxide in the obtained tin oxide is 94.4%.

Embodiment 3

[0031] With the waste solder powder after mechanical crushing treatment as raw material (tin content 65.4%), raw material is mixed with the additive of 10% of waste solder mass (component by weight of additive: 60 parts of inert aluminum oxide, 36 parts of silicon dioxide , 4 parts of stannous oxide) after mixing evenly, carry out briquetting treatment, place the obtained agglomerates in a weak oxidizing atmosphere after drying and roasting at 875°C for 120min; the weak oxidizing atmosphere is composed of oxygen, carbon dioxide and nitrogen, of which oxygen and carbon dioxide The volume percentages are 1% and 8% respectively, and the balance gas is nitrogen; the tin oxide is recovered, the tin recovery rate is 87.9%, and the tin dioxide purity in the tin oxide is 95.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com