Reduction box of aerator and impeller type aerator provided with reduction box

A kind of technology of aerator and reducer, which is applied to components with teeth, belts/chains/gears, transmission boxes, etc., which can solve the problems of troublesome machining and heavy weight, and achieve the effect of simple machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

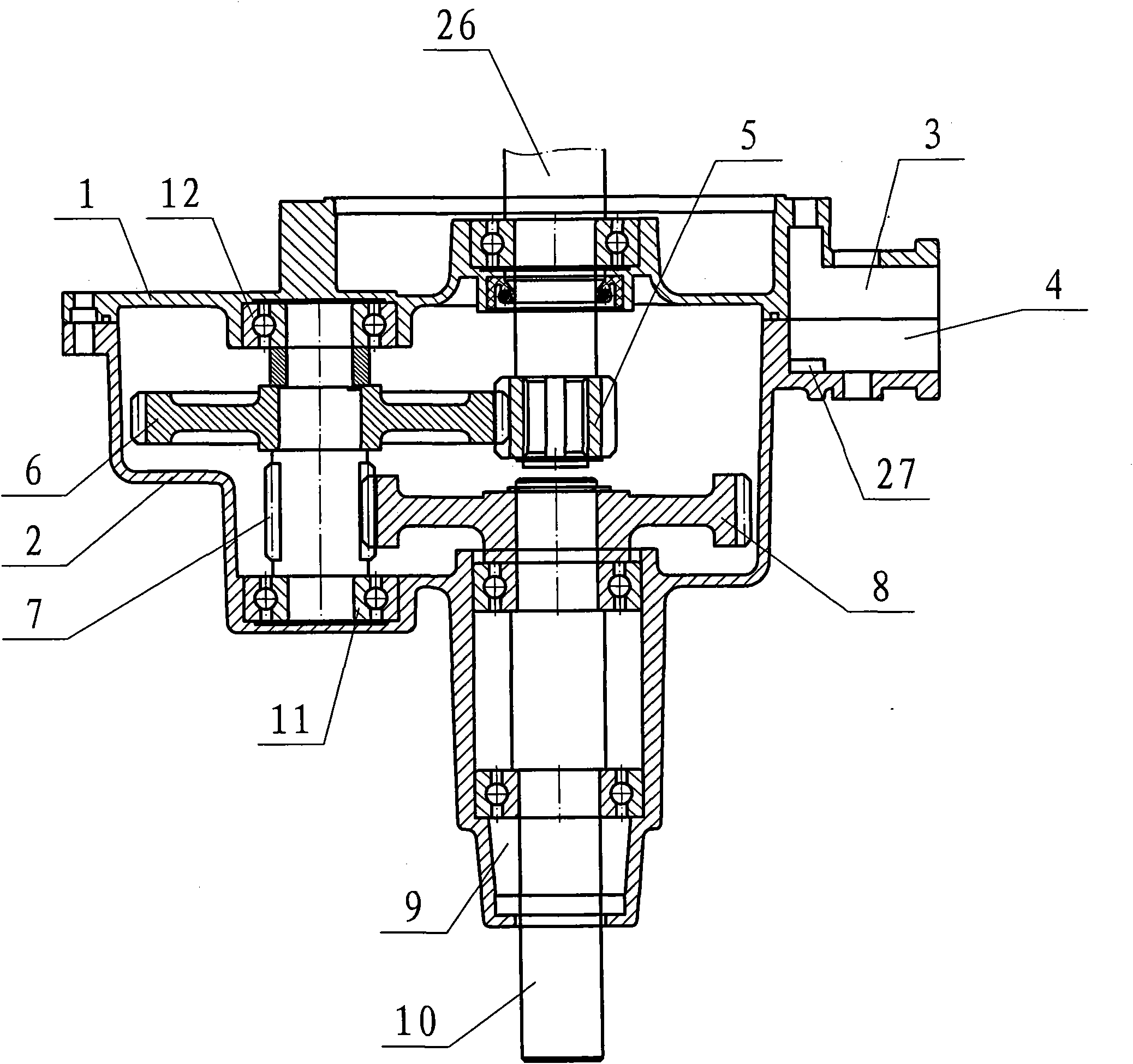

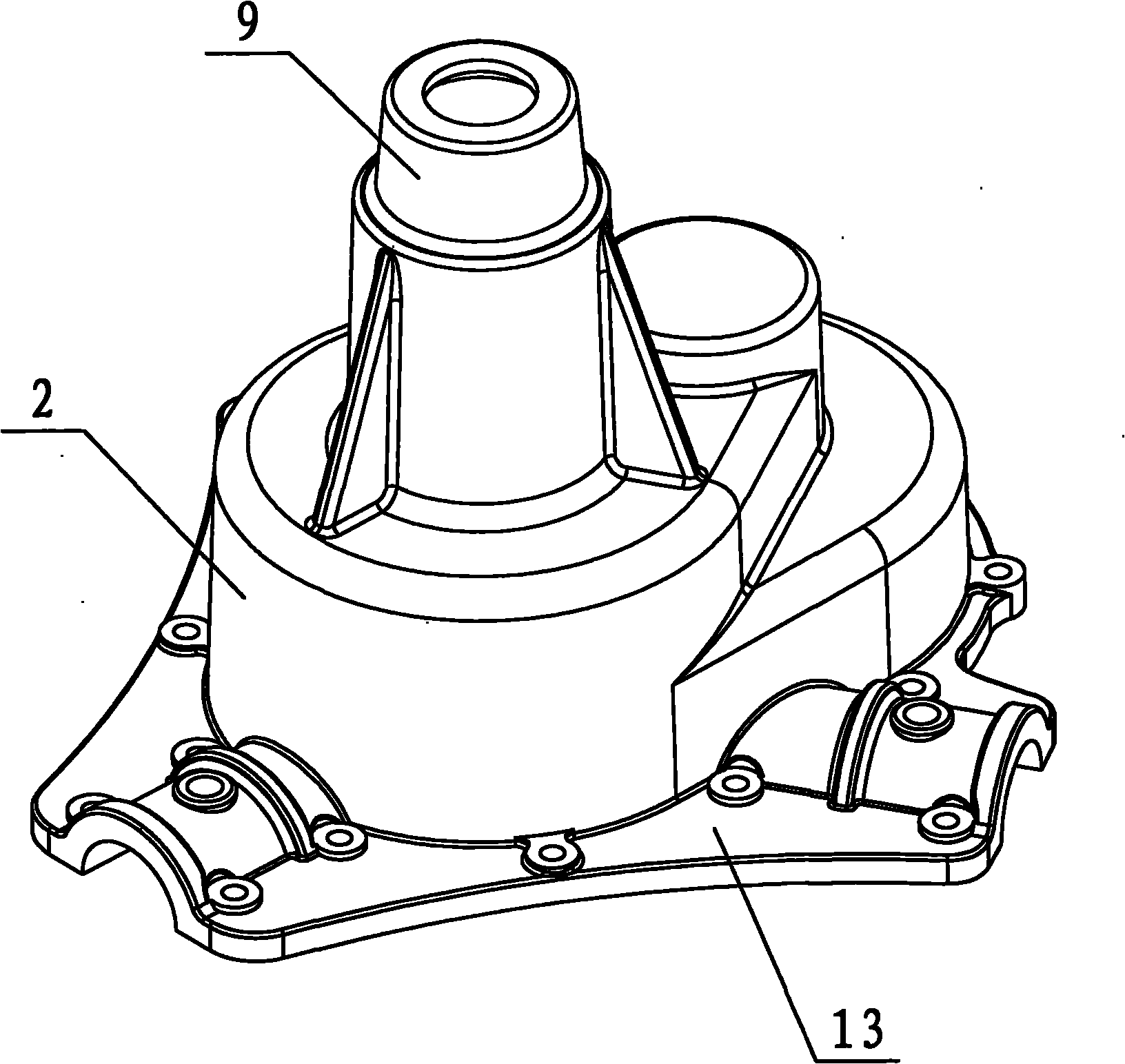

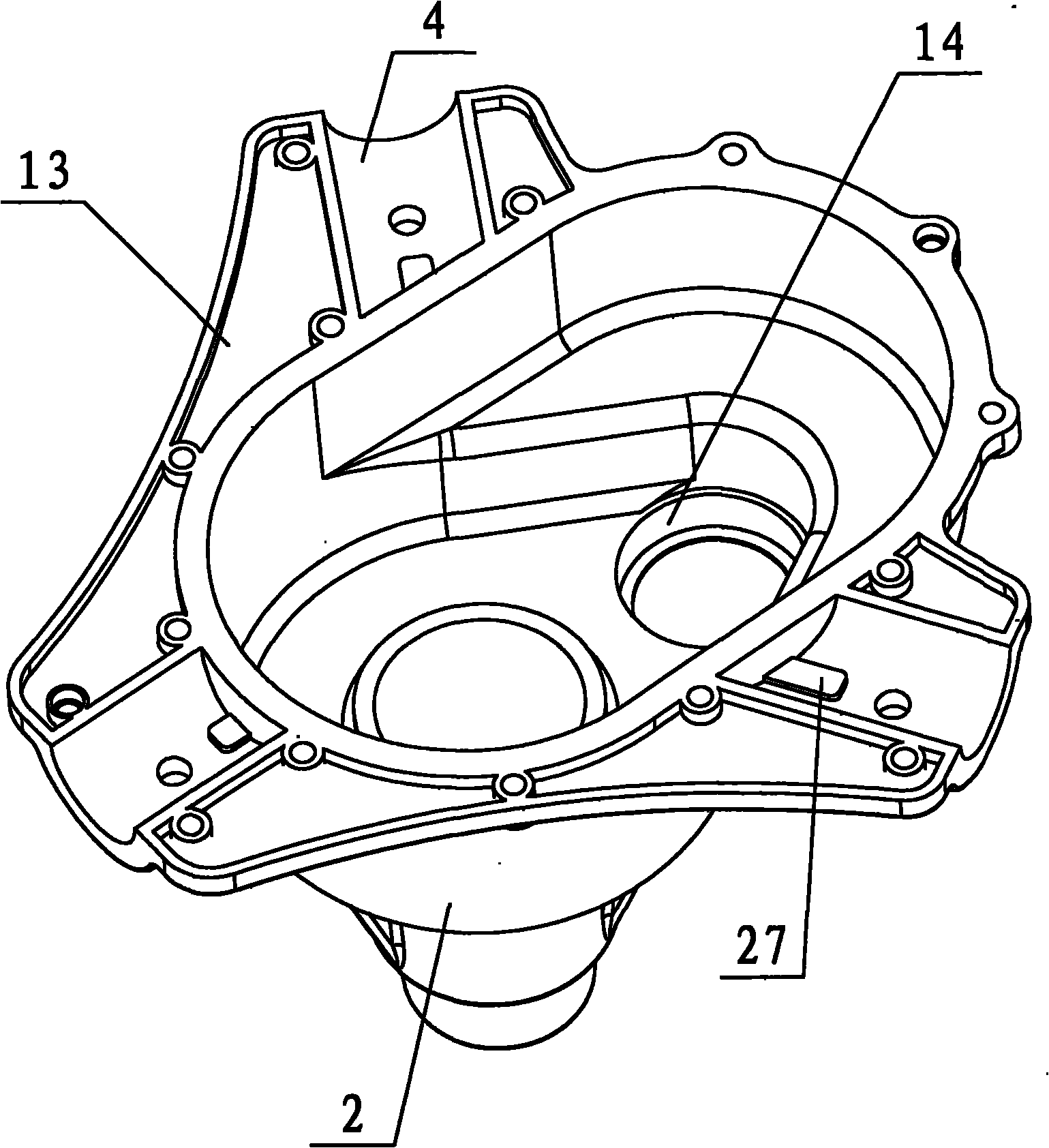

[0028] The present invention will be further described below with specific embodiment, see Figure 1-8 :

[0029] An alloy aluminum die-casting reduction box for an impeller-type aerator is mainly composed of: a box body 2, an upper cover 1, a secondary reduction gear, a bearing, an output shaft 10, etc., and there are three junctions between the box body 2 and the upper cover 1 The semicircular grooves of support rod 21 can be installed, and the semicircular grooves are evenly distributed in three equal parts, and casing 2 and loam cake 1 are fastened and sealed with bolts 23. Two semi-circular grooves become a circular hole, and the support rod 21 is installed in the circular hole. For the accurate positioning of the support rod 21 in the circular hole, a positioning boss 27 is formed in the semi-circular groove, and a gap 28 is formed in the support rod 21. , The notch 28 is matched with the positioning boss 27. The hexagonal head of the hexagonal bolt 22 passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com