Delay colored Petri network-based steel rolling system modeling method

A system modeling and non-ferrous technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as complex system model structure, large model space, difficulty in model establishment and expansion, etc., to achieve clear modeling process, The effect of simplifying the structure and size of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

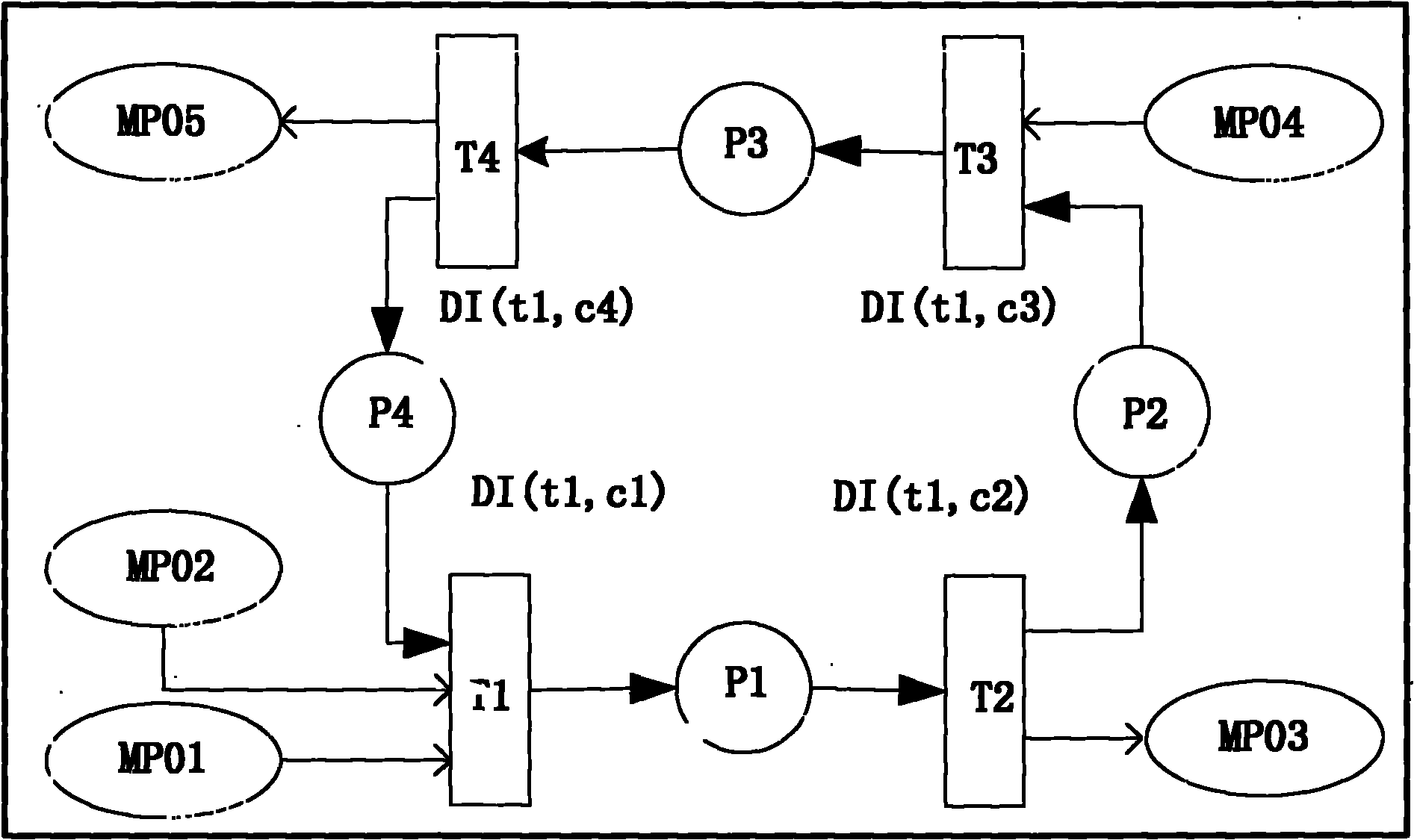

[0057]In order to illustrate how to use time-delayed colored Petri nets to realize the modeling of steel rolling logistics system, the production line of a steel company's rod and wire factory is taken as an example. In the production line of the rod and wire factory, there is one heating furnace, one preliminary rolling mill, four intermediate rolling mills, and four finishing rolling mills. The cranes are divided into two groups. The first group has two to realize the transportation of raw materials; The platform realizes the storage of finished parts, the movement of middleware and the removal of waste products.

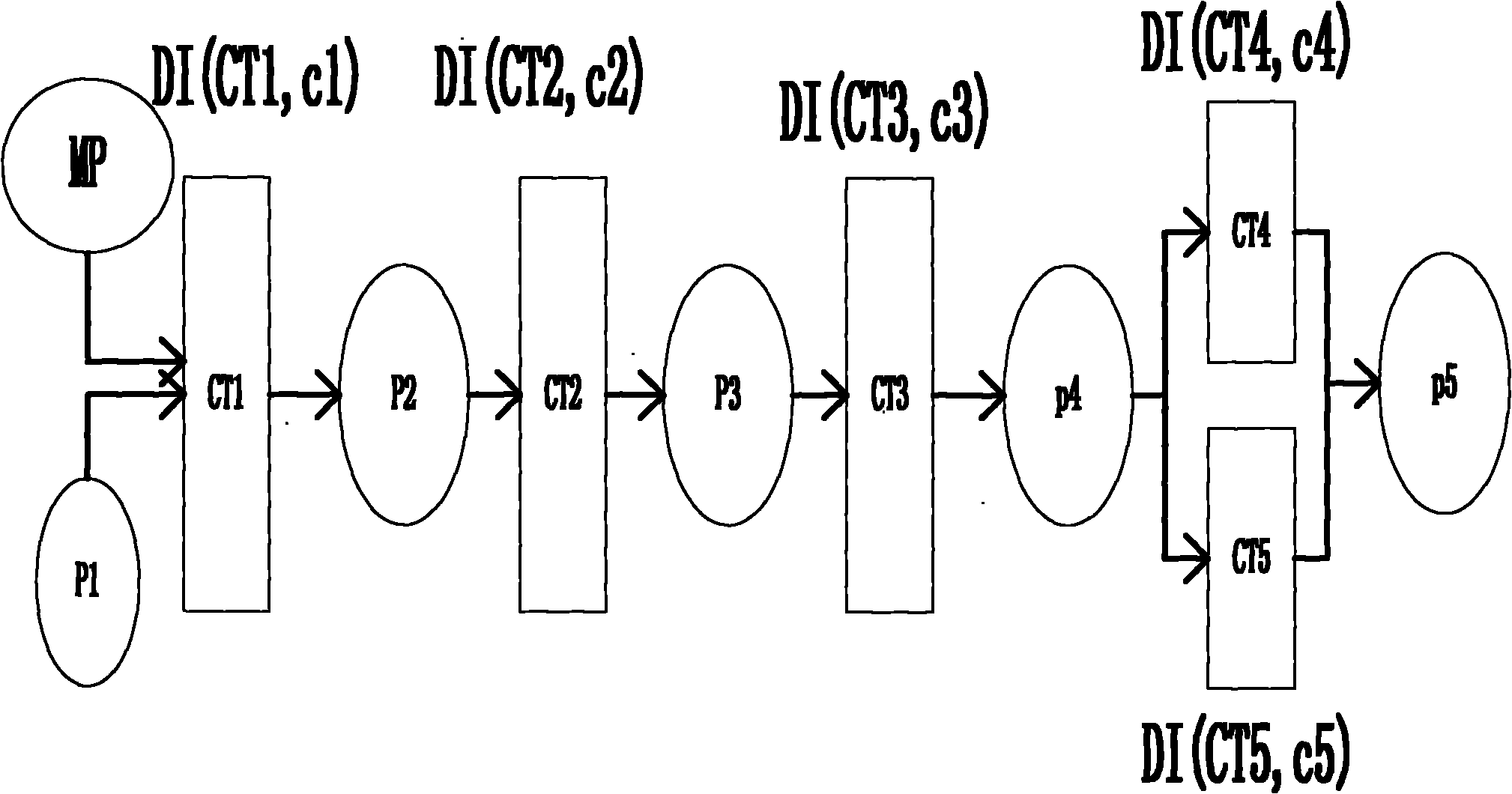

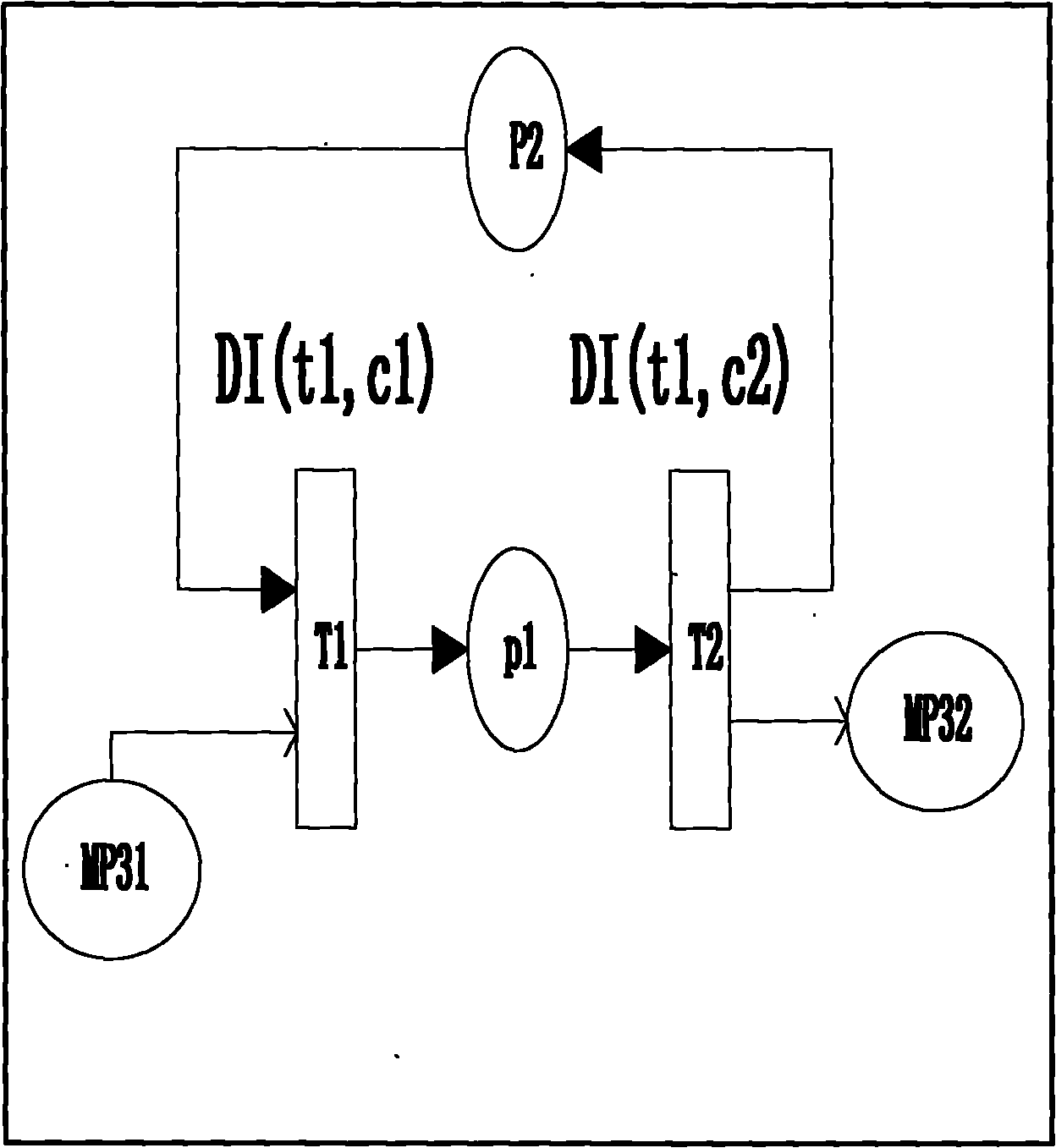

[0058] Firstly, design the whole steel rolling system, without considering the detailed activity process inside each station, and build the top-level model (home page) of the system by using the layered characteristics of colored Petri nets. On this basis, the internal detailed activities of each station are modeled. Since the workflows of rough rolling, intermed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com