Photovoltaic array component with fault detecting device

A fault detection, photovoltaic array technology, applied in the monitoring of photovoltaic power generation, photovoltaic modules, photovoltaic systems, etc., can solve the problems of poor timeliness, high cost of thermal imagers, long time for temperature changes, etc., to achieve long service life, Low cost, quick response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

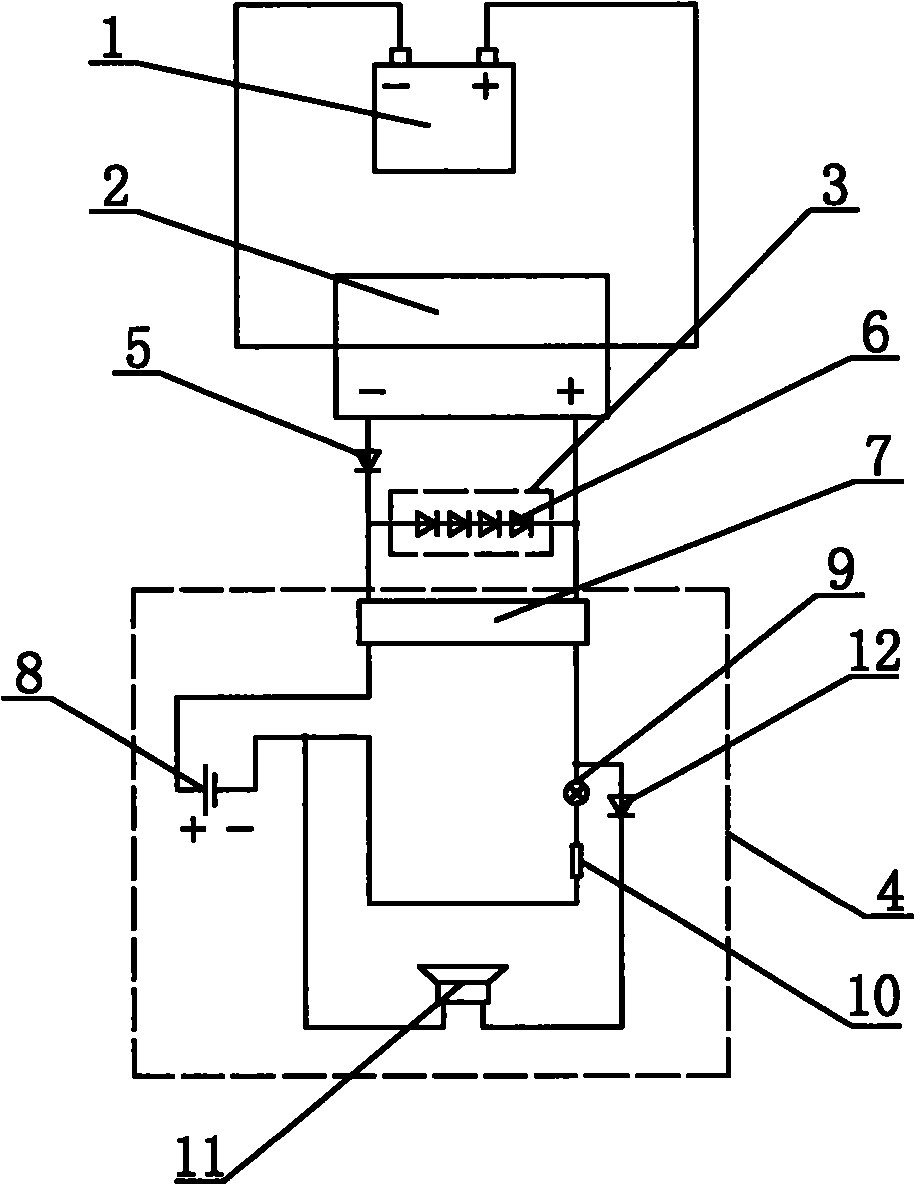

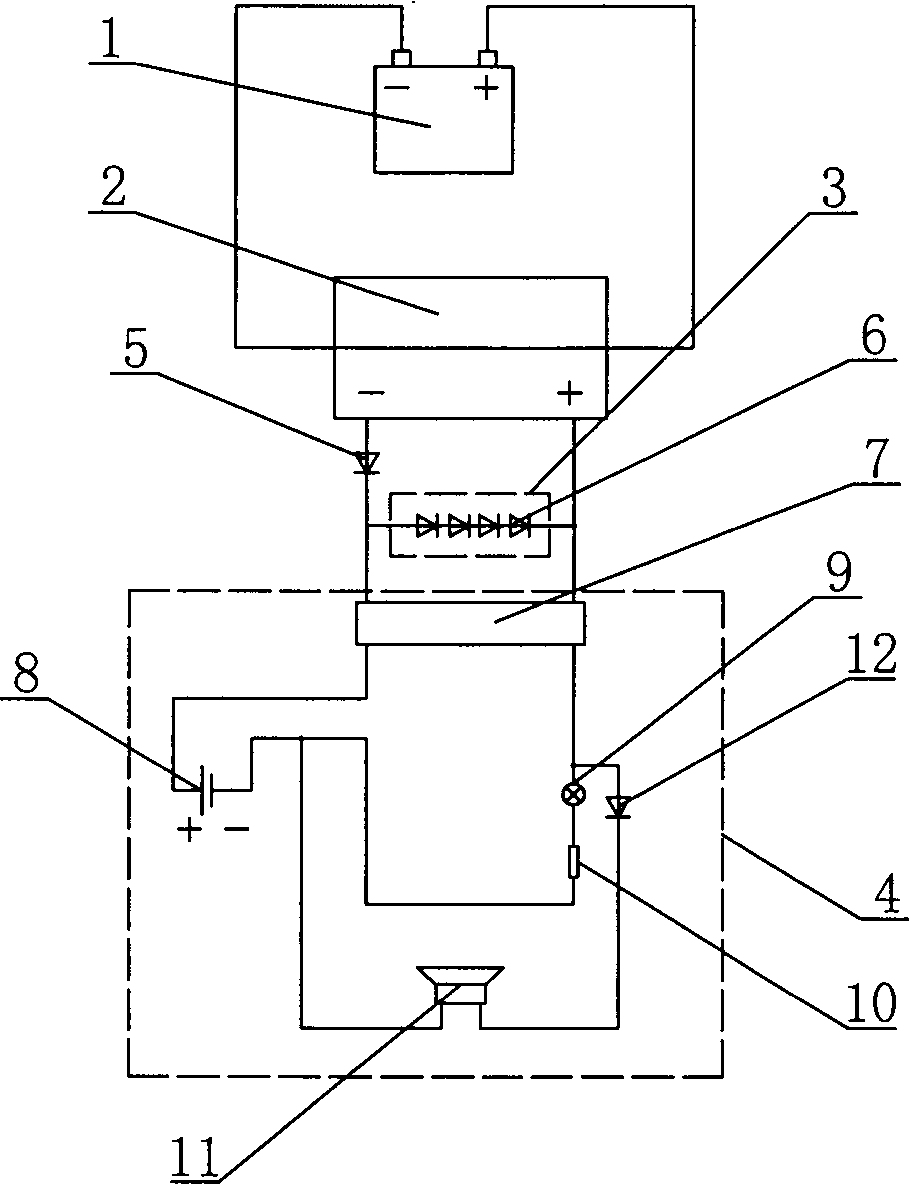

[0031] like figure 1 As shown, a photovoltaic array assembly with a fault detection device, the photovoltaic array assembly with a fault detection device includes a bypass diode group 3, a fault detection device 4, a storage battery 1 and a photovoltaic assembly 2, the The photovoltaic module 2 is connected in series with the storage battery 1; the bypass diode group 3 is connected in series with a diode 5, and the circuit composed of the bypass diode group 3 and a diode 5 connected in series is connected in parallel with the photovoltaic module 2 The fault detection device 4 is connected in parallel with the bypass diode group 3 .

[0032] The bypass diode group 3 includes four diodes 6 .

[0033] Described fault detection device 4 comprises voltage type relay 7, external power supply 8, light alarm 9, protective resistor 10 and sound alarm 11, and described light alarm 9 is LED indicator light, and described sound alarm 11 is buzzer; the voltage-type relay 7, the external ...

Embodiment 2

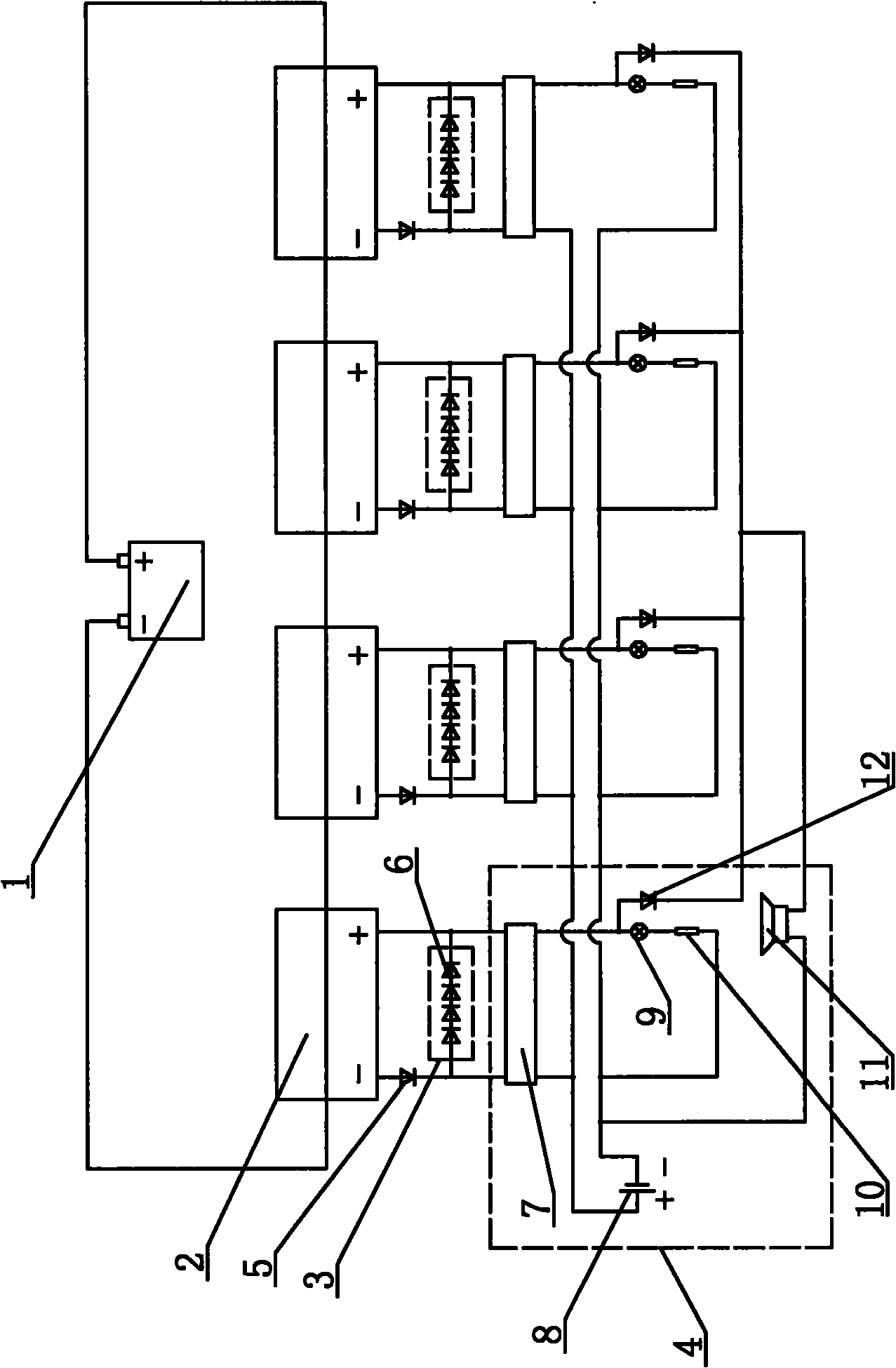

[0035] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that: the photovoltaic array assembly with fault detection device includes four sets of bypass diode groups 3, four fault detection devices 4, one storage battery 1 and four photovoltaic Assemblies 2, the four photovoltaic modules 2 are connected in series and are connected in series with the battery 1; the bypass diode group 3 is connected in series with a diode 5, and the bypass diode group 3 is connected in series with a diode 5 The formed circuit is connected in parallel with the photovoltaic module 2 respectively, and the fault detection device 4 is respectively connected in parallel with the bypass diode group 3, and each group of bypass diode group 3 includes four diodes 6.

[0036] Each of the fault detection devices 4 described includes a voltage type relay 7, an external power supply 8, a light alarm 9, a protection resistor 10 and an acoustic alarm 11, and the four fault dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com