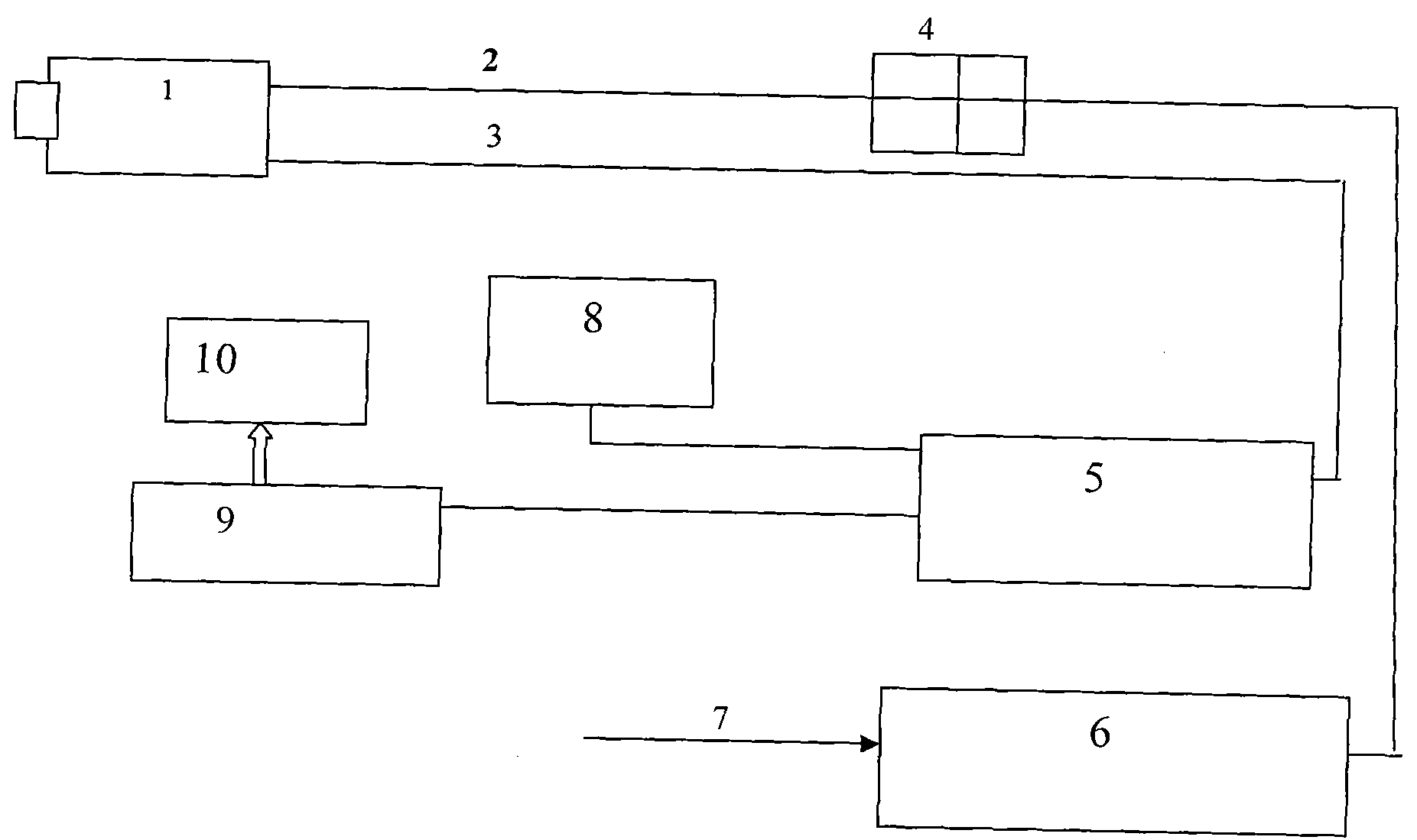

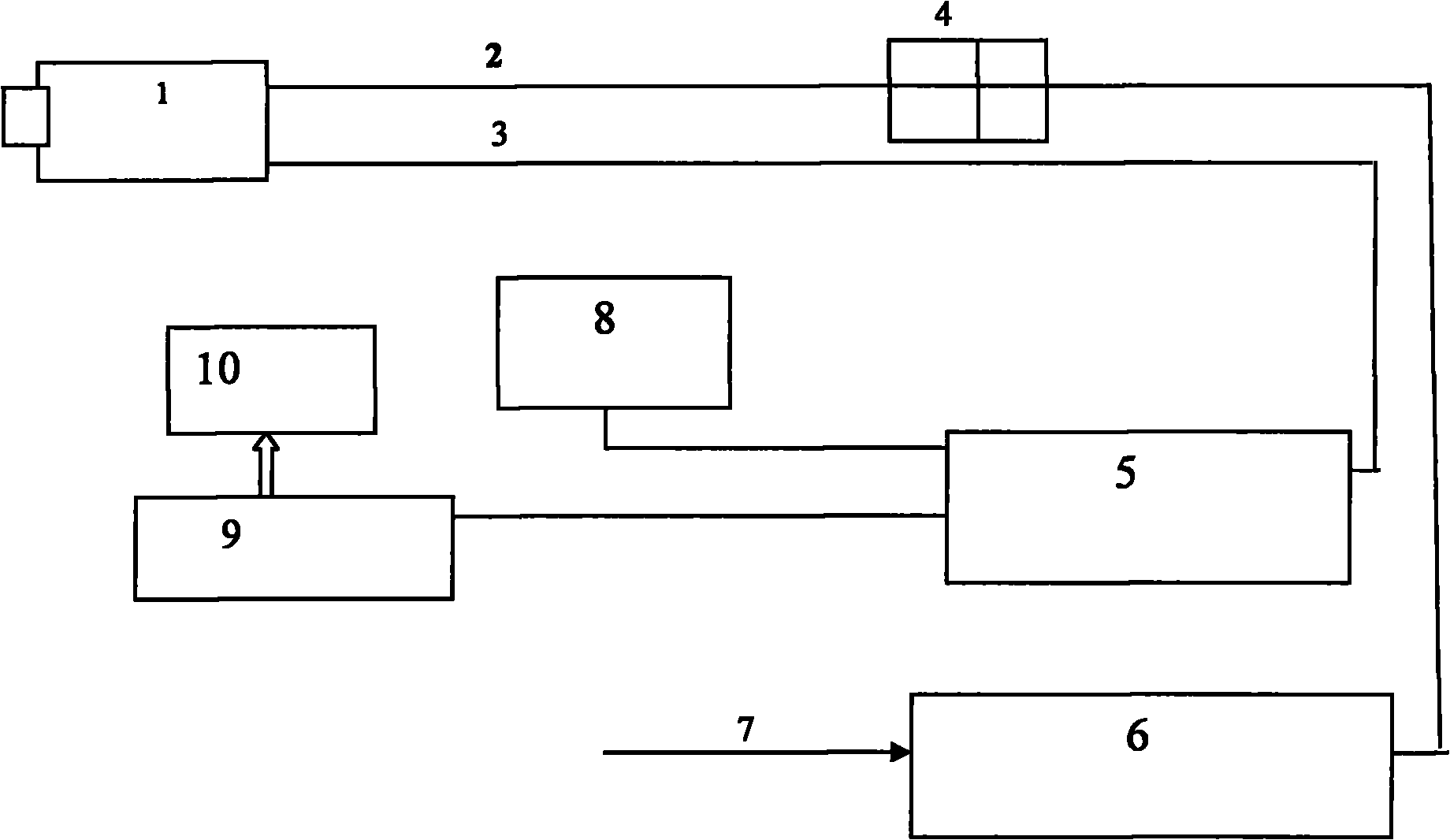

Sintering machine infrared imaging temperature measuring system

A technology of infrared imaging and sintering machine, which is applied in the direction of closed-circuit television system, TV system components, measuring devices, etc., to achieve the effect of simple hard disk video recording function and clear image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] Working condition of the present invention:

[0061] Cooling water for water-cooled air seal boots:

[0062] Contact inlet pressure: 0.1~0.4Mpa

[0063] Flow rate: 0.3~1.5m 3 / h

[0064] PH value = 6-8.

[0065] Water-cooled air-sealed protective sleeve air-sealed nitrogen:

[0066] Contact inlet pressure: 0.3~0.6Mpa

[0067] Flow rate: 1.0~3.0m 3 / h.

[0068] System power supply: AC220V 200W.

[0069] The advantages of the present invention are:

[0070] 1) The infrared imaging temperature measurement system adopts the latest ultra-low illumination infrared camera and wide-angle high-temperature resistant lens to ensure long-term and stable work under the normal production of the sintering machine.

[0071] 2) Through the developed sintering machine temperature analysis system software, which integrates image acquisition, video analysis and temperature analysis, it can observe the temperature changes of the sintering machine head and tail in a timely and intui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com