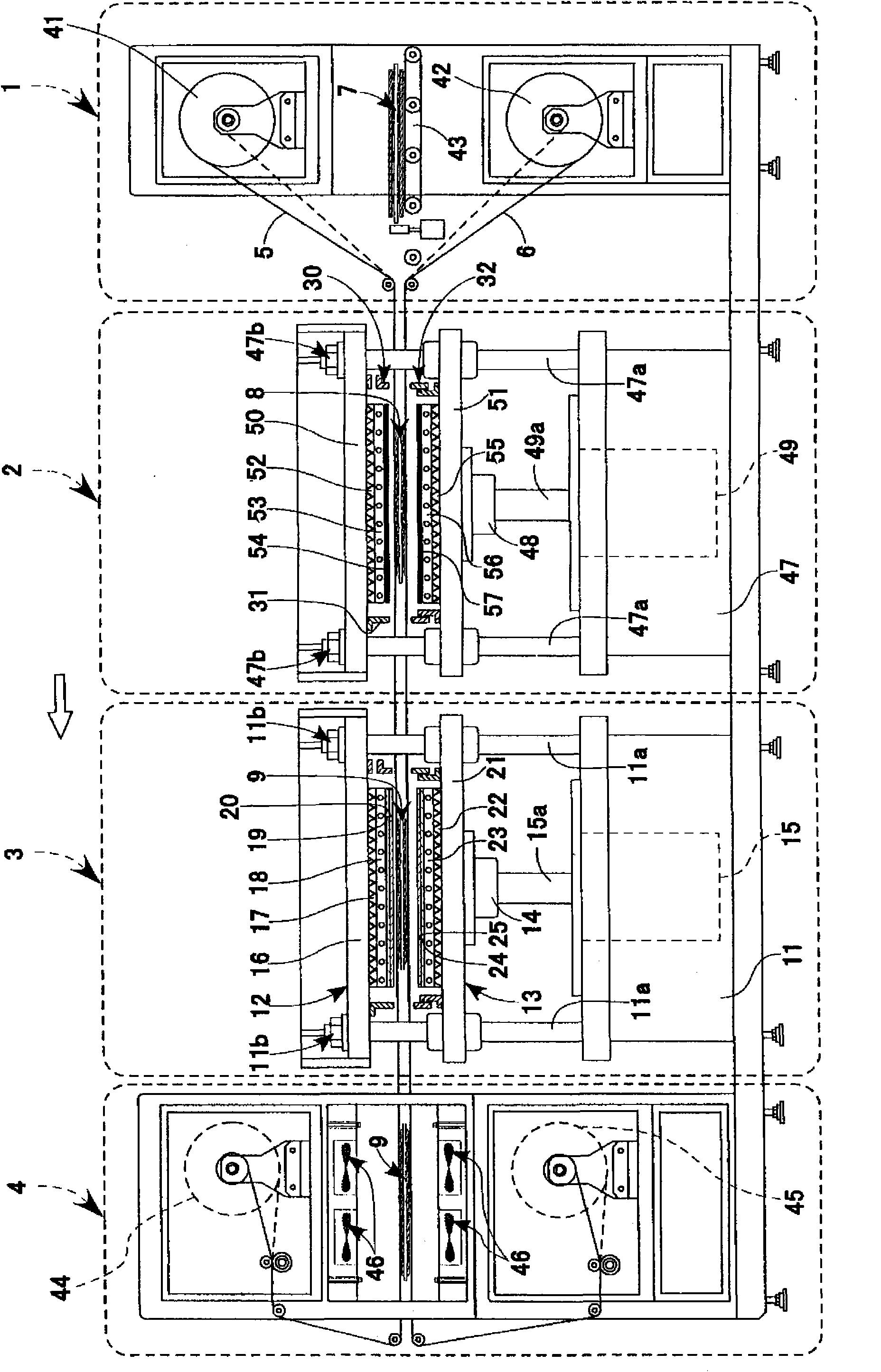

Flat pressing machine, laminating apparatus and laminating method using flat pressing machine and laminating apparatus

A stamping device and plane technology, which is applied in the field of plane stamping devices and lamination devices, can solve problems such as product quality degradation and defective products, and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

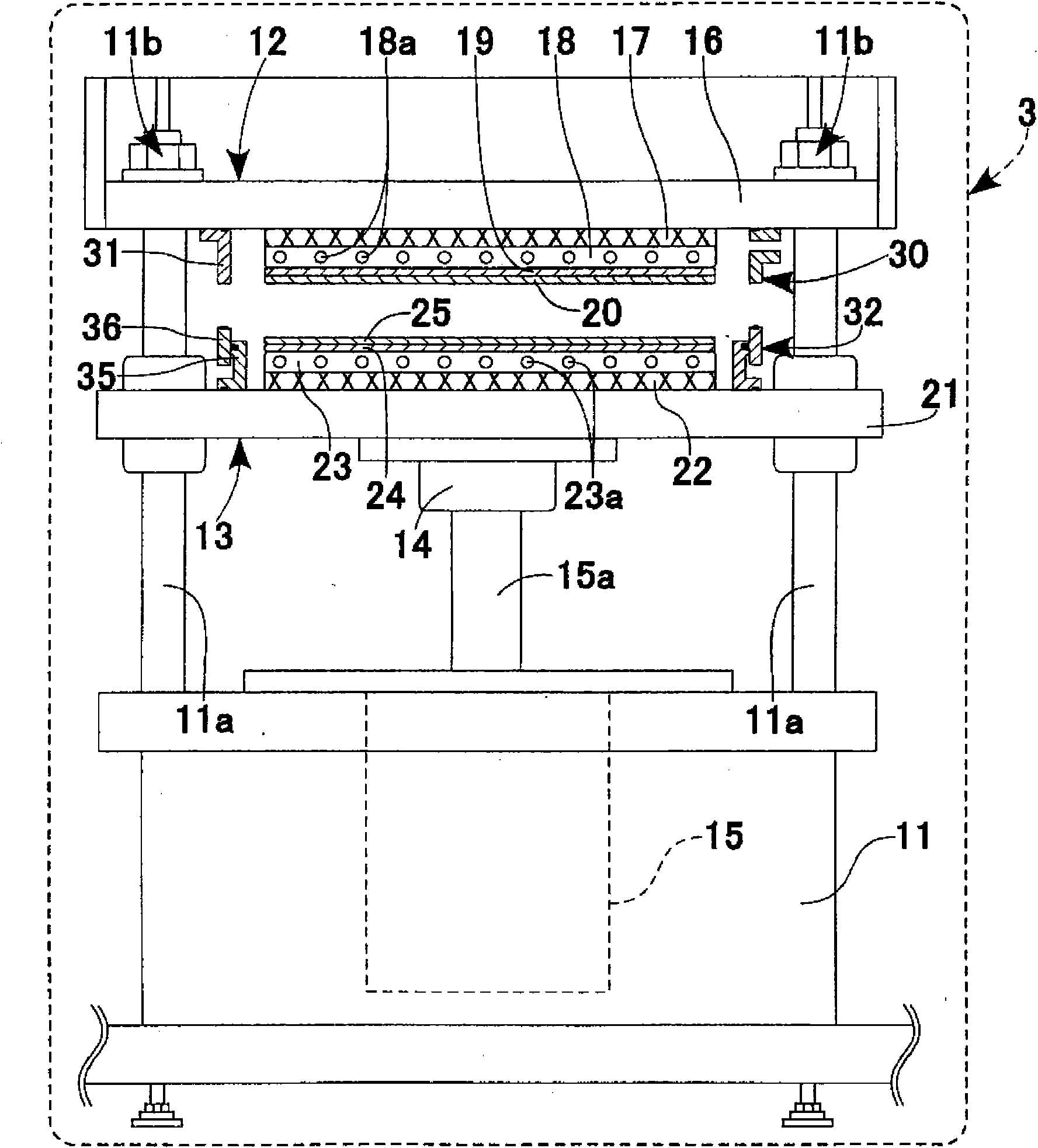

Method used

Image

Examples

Embodiment 1~8 and comparative example 1~8

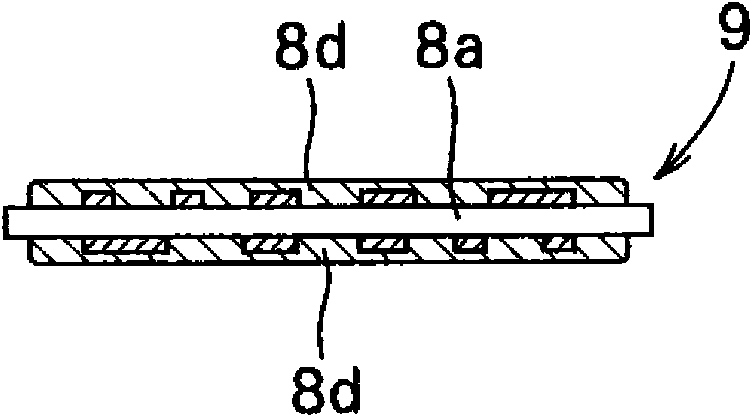

[0118] Laminates were prepared under the conditions shown in Tables 1 and 2 below. That is, in Examples 1 to 8 and Comparative Examples 1 to 8, the pattern on the substrate 8a is on both surfaces of the substrate 8a, the parallel lines of L (line) / S (space)=50 / 50 μm and Parallel lines of L (line) / S (space)=50 / 50000 μm (=5 cm) are orthogonal. In addition, the height of the prepared pattern (the depth of the unevenness of the uneven surface of the substrate 8a) was three types of 35 μm, 50 μm, and 70 μm, respectively.

Embodiment 9~16 and comparative example 9~16

[0120] Laminates were prepared under the conditions shown in Tables 3 and 4 below. That is, in Examples 9-16 and Comparative Examples 9-16, the pattern on the base material 8a was prepared as four structures of following (1)-(4), respectively. In addition, the height of each pattern was set to 35 μm.

[0121] (1) On both surfaces of the substrate 8a, the parallel line of L / S=50 / 50 μm is perpendicular to the parallel line of L / S=50 / 50000 μm.

[0122] (2) On both surfaces of the substrate 8a, the parallel line of L / S=50 / 500 μm is perpendicular to the parallel line of L / S=50 / 50000 μm.

[0123] (3) On both surfaces of the substrate 8a, the parallel line of L / S=50 / 3000 μm is perpendicular to the parallel line of L / S=50 / 50000 μm.

[0124] (4) On both surfaces of the substrate 8a, the parallel line of L / S=50 / 30000 μm is perpendicular to the parallel line of L / S=50 / 50000 μm.

[0125] In addition, in Examples 1 to 4 and 9 to 12 and Comparative Examples 1, 3, 5, 7 and 9, 11, 13, and ...

Embodiment 17~20 and comparative example 17~20

[0147] A laminate was produced under the conditions shown in Table 5 below. That is, in Examples 17-20, the laminated body 9 was produced under the same conditions as Examples 1-4. In Comparative Examples 17 to 20, laminated body 9 was produced under the same conditions except that the pressure reduction performed in the flat press part in Examples 5 to 8 was not performed.

[0148] Then, with respect to the laminated body 9 of said Examples 17-20 and Comparative Examples 17-20, the defect of the peripheral edge part of a resin layer and the adhesion of a resin layer to a tape-shaped film were evaluated by the following procedure.

[0149] Defects in the peripheral part of the resin layer

[0150] The peripheral part of the smoothed resin layer 8d laminated on the base material 8a was visually observed, and whether the peripheral part of the resin layer 8d was chipped was evaluated as follows.

[0151] ◯...There is a resin chip around the resin layer 8d.

[0152] ×... The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com