Three-crystalline phase composite molecular sieve and preparation method thereof

A composite molecular sieve and molecular sieve technology, which is applied in molecular sieve catalysts, chemical instruments and methods, bulk chemical production, etc., can solve problems such as failure to synthesize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

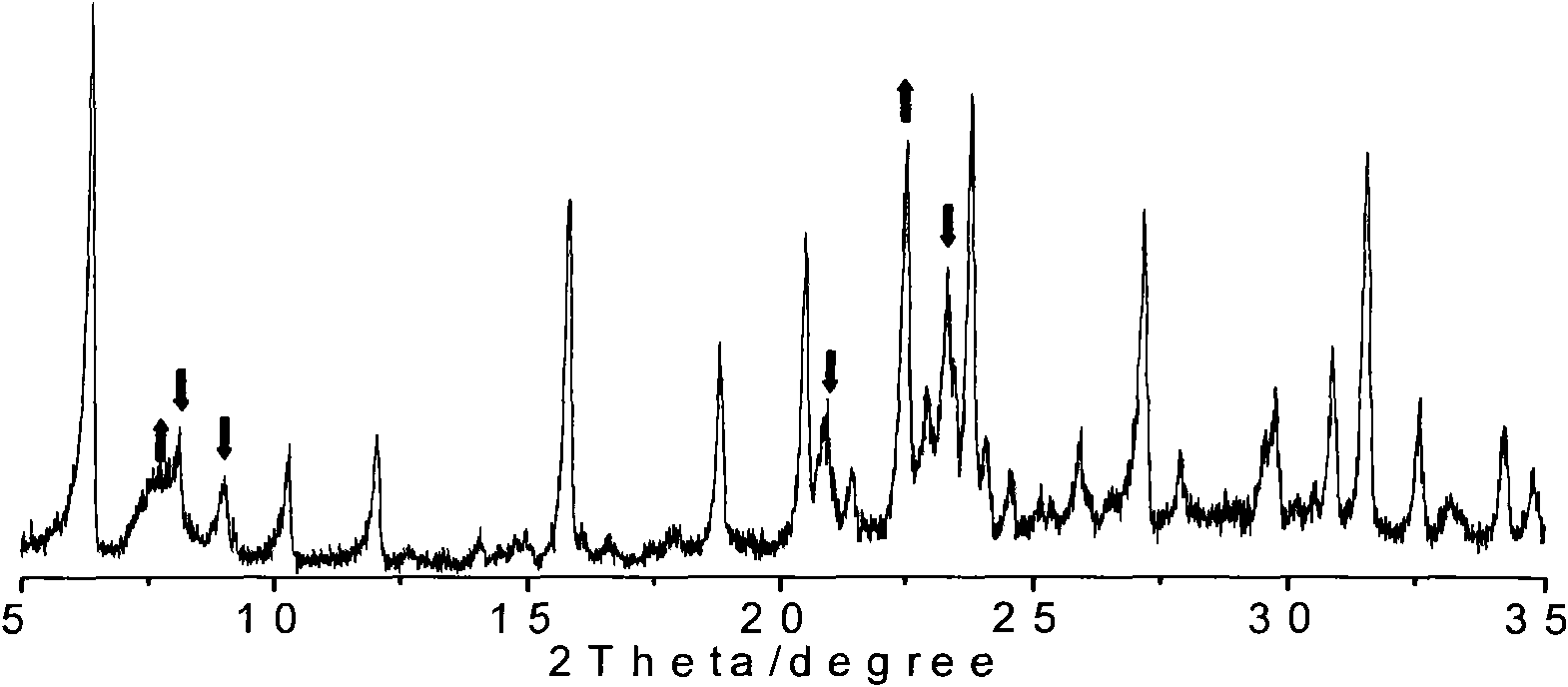

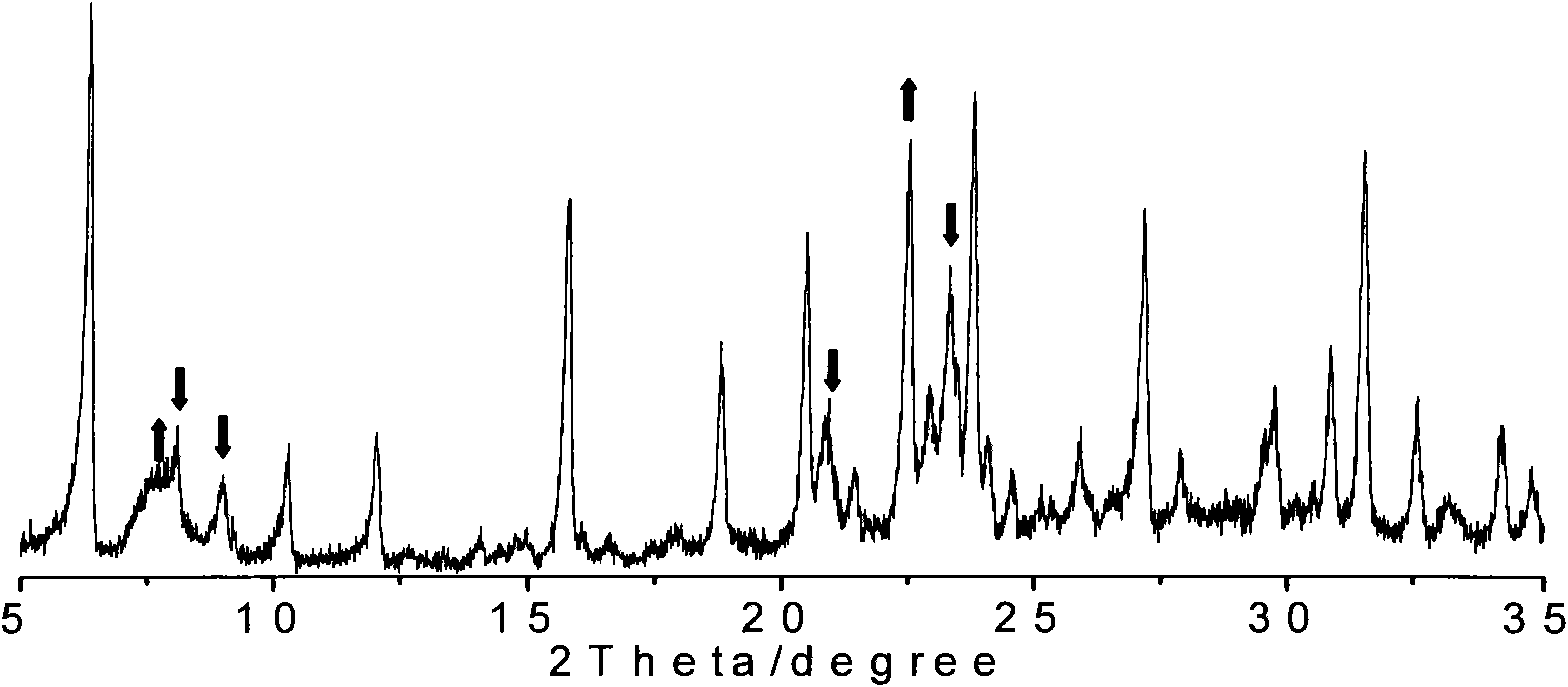

Image

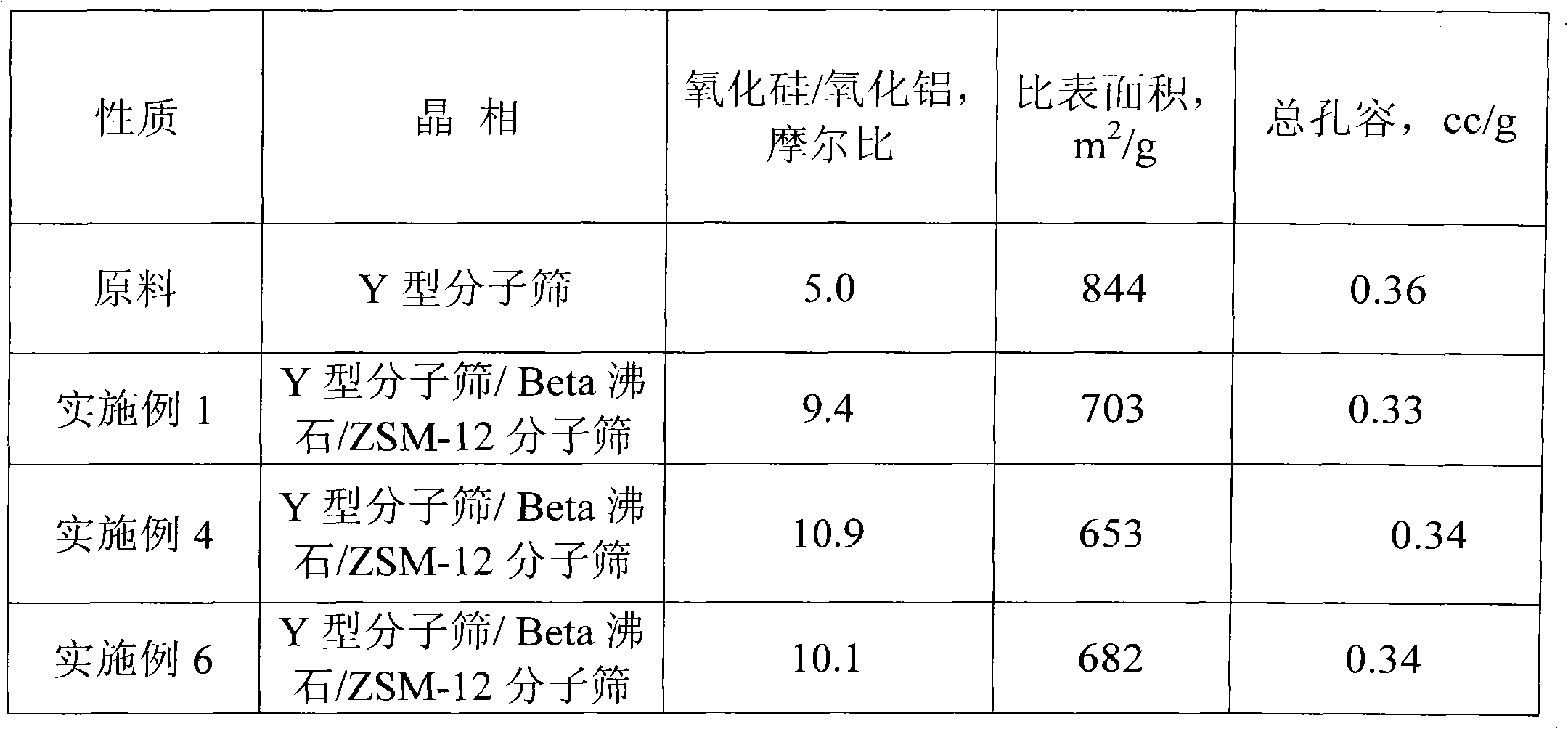

Examples

Embodiment 1

[0022] Weigh 5.4g of sodium hydroxide and 100g of TEABr and dissolve them in 325ml of deionized water, then add 144g of Y-type molecular sieves while stirring, and then add 40ml of concentrated ammonia water after mixing evenly, stir for half an hour, then add 205ml of silica sol, stir for 2 hours, and then move to In a closed stainless steel reactor. Crystallize at 140° C. for 7 days to obtain a molecular sieve product. Proportion: 1.07Na 2 O: 9.0 SiO 2 : 1.5TEABr : 3.25NH 4 OH:Al 2 o 3 : 100H 2 O.

Embodiment 2

[0024] Weigh 5.4g of sodium hydroxide and 100g of TEABr and dissolve them in 305ml of deionized water, then add 144g of Y-type molecular sieve while stirring, and then add 60ml of concentrated ammonia water after mixing evenly, stir for half an hour, then add 205ml of silica sol, stir for 2 hours, and then move to In a closed stainless steel reactor. Crystallize at 145° C. for 5 days to obtain a molecular sieve product. Proportion: 1.07Na 2 O: 9.0 SiO 2 : 1.5TEABr : 4.88NH 4 OH:Al 2 o 3 : 100H 2 O.

Embodiment 3

[0026] Weigh 5.8g of sodium hydroxide and 100g of TEABr and dissolve them in 330ml of deionized water, then add 144g of Y-type molecular sieves while stirring, and then add 40ml of concentrated ammonia water after mixing evenly, stir for half an hour, then add 205ml of silica sol, stir for 2 hours and then move to In a closed stainless steel reactor. Crystallize at 140° C. for 7 days to obtain a molecular sieve product. Proportion: 1.08Na 2 O: 9.0 SiO 2 : 1.5TEABr : 3.25NH 4 OH:Al 2 o 3 : 101H 2 O.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com