Artificial turf masterbatch and preparation method thereof

A technology of artificial turf and color masterbatch, which is applied in the field of plastic functional masterbatch, which can solve the problems of single color masterbatch, lack of suppleness, smooth feel, anti-aging and wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

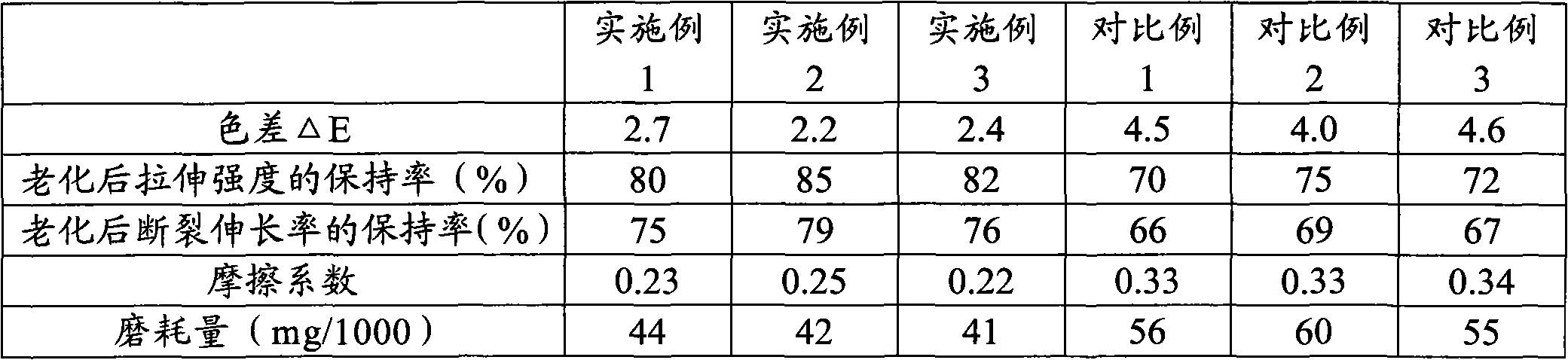

Examples

Embodiment 1

[0028] A smooth wear-resistant and weather-resistant artificial grass color masterbatch; including 10% of light stabilizer bis(2,2,6,6-tetramethylpiperidinol) sebacate and ultraviolet absorber calculated by weight percentage 2-Hydroxy-4-n-octyloxybenzophenone 5%, antioxidant β[3-(3,5-di-tert-butyl-4-hydroxyphenyl)] propionate 2.5%, heterocyclic Pigment 20%, smooth agent ultra-high molecular weight polysiloxane 40%, dispersant polyethylene wax 5% and carrier resin LDPE17.5%.

[0029] The preparation method of the smooth wear-resistant and weather-resistant artificial grass silk masterbatch is as follows: first mix the above materials at high speed for 3 minutes, and then use a twin-screw extruder to melt and extrude at 100°C to 160°C to obtain the required granules.

Embodiment 2

[0031] A smooth, wear-resistant and weather-resistant artificial grass color masterbatch; including light stabilizer poly[[6-[(1,1,3,3-tetramethylbutyl)amine]-1,3 , 5-triazine-2,4-diyl][(2,2,6,6-tetramethyl-4-piperidine)imine]-1,6-dihexanediyl[(2,2, 20% , UV absorbers 2-(2-hydroxy-3-tert-butyl-5-methylphenyl)-5-chlorobenzotriazole and 2-(2'-hydroxy-3',5'-di-tert-butyl 8% mixture of phenyl)-5-chlorobenzotriazole, antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate and tri(2 , 4-di-tert-butylphenyl) phosphite mixture 8%, titanium dioxide and azo pigment 10%, smooth agent ultra-high molecular weight polysiloxane 20%, dispersant ethylene-vinyl acetate copolymer wax 10%, carrier resin LLDPE24%.

[0032] The preparation method of the smooth wear-resistant and weather-resistant artificial grass silk color masterbatch is as follows: first mix the above materials at high speed for 6 minutes, then use a twin-screw extruder to melt and extrude at 100°C to 160°C to f...

Embodiment 3

[0034] A smooth, wear-resistant and weather-resistant artificial grass color masterbatch; including light stabilizer poly(4-hydroxy-2,2,6,6-tetramethyl-1-piperidine succinate) calculated by weight percentage 12%, UV absorber 2-(2'-hydroxy-3', 5'-di-tert-butylphenyl)-5-chlorobenzotriazole 4%, antioxidant β[3-(3,5 -di-tert-butyl-4-hydroxyphenyl)] pentaerythritol propionate 3%, ultramarine and heterocyclic pigments 15%, slip agent ultra-high molecular weight polysiloxane 15%, fatty acid amide 5%, dispersant polyamide Wax 6%, carrier resin LDPE 40%.

[0035] The preparation method of the smooth wear-resistant and weather-resistant artificial grass silk masterbatch is as follows: first mix the above materials at high speed for 10 minutes, then use a twin-screw extruder to melt and extrude at 100°C to 160°C to form the required granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com