Curved platelike three-dimensional angle-interlock fabric and method for weaving same

An angle interlocking and fabric technology, applied in the direction of fabrics, textiles, papermaking, textiles, etc., can solve the problems of restricting the development of plate-shaped three-dimensional angle interlocking fabrics, affecting the properties of fabric materials, and poor fiber continuity, and achieving convenient and practical Application, weaving time saving, effect of saving yarn usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

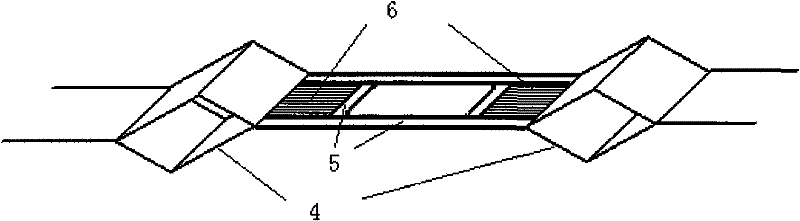

[0046] Such as Figure 4 Shown, adopt the method of the present invention to weave S-shaped fabric.

[0047] Suppose the width of the S-shaped fabric is 4cm, the length of the first straight section is 10cm; the angle of the first fillet θ is 180° clockwise, and the inner radius of the fillet is R 2 is 4cm, the outer radius is 8cm; the length of the second straight section fabric is 8cm; the second fillet angle θ is 180° counterclockwise, and the inner radius is R 2 is 4cm, the outer radius R 1 It is 8cm; the length of the third straight section fabric is 10cm. Assuming that the warp yarn density is 120 / layer / 10cm, the weft yarn density is 3 / layer / 10cm, and the number of fabric layers is 6 layers. Then the inner arc length L 2 is 12.56cm, the outer arc length L 1 is 25.12cm, and the number of weft yarns in a single layer of weaving inner arc length fabric is Z 2 It is 12.56×3=37.68 wefts, rounded up to 38 wefts; weaving outer arc length fabric single-layer weft number Z ...

example 2

[0050] Such as Figure 5 Shown, adopt the method of the present invention to weave U-shaped fabric.

[0051] Suppose the length of the straight section of the fabric is 10cm, the width is 8cm, the fillet angle θ is 180°, and the fillet inner radius R 2 4cm, outer radius R 1 12cm. Assume that the warp yarn density is 120 / layer / 10cm, the weft yarn density is 3 / layer / 10cm, and the number of fabric layers is 6. Then the inner arc length L 2 is 12.56cm, the outer arc length L 1 is 37.68cm, and the number of weft yarns in a single layer of weaving inner arc length fabric is Z 2 It is 12.56×3=37.68 wefts, rounded up to 38 wefts; weaving outer arc length fabric single-layer weft number Z 1 It is 37.68×3=75.24 latitudes, and rounded to 76 latitudes. Group a is 76 / 38=2 groups, the theoretical minimum rotation angle α 0 The degree is 180° / 38≈4.7°, which is rounded to 5°. For the convenience of weaving, the rotation angle α is set to 6×5°=30°. According to warp density and fabric...

example 3

[0054] Such as Figure 6 As shown, the method of the present invention is used to weave curved plate-shaped non-closed endless fabric.

[0055] Assume that the fabric is an unclosed square-like ring fabric with rounded corners, with a width of 4cm, rounded corners θ are clockwise at 90°, and the inner radius of the rounded corners is R 2 4cm, outer radius R 1 8cm; the first straight section is 12cm long, the second, third, and fourth straight sections are all 20cm, and the fifth straight section is 12cm; the warp yarn density is 120 / layer / 10cm, and the weft yarn density is 3 / Layers / 10cm, 6 fabric layers. Then the inner arc length L 2 is 6.28cm, the outer arc length L 1 is 12.56cm, and the number of weft yarns in a single layer of weaving inner arc length fabric is Z 2 It is 6.28×3=18.84 wefts, 19 wefts are taken by carry; weaving outer arc length fabric single-layer weft number Z 1 It is 12.56×3=37.68 wefts, rounded to 38 wefts. Group a is 38 / 19=2 groups, the theoretic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com