Urea mixing device

A technology of mixing device and urea, which is applied in the direction of muffler, exhaust device, mechanical equipment, etc., can solve the problems of ammonia leakage, reduce sediment, etc., achieve the effect of improving NOx conversion efficiency and reducing the uneven distribution of ammonia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

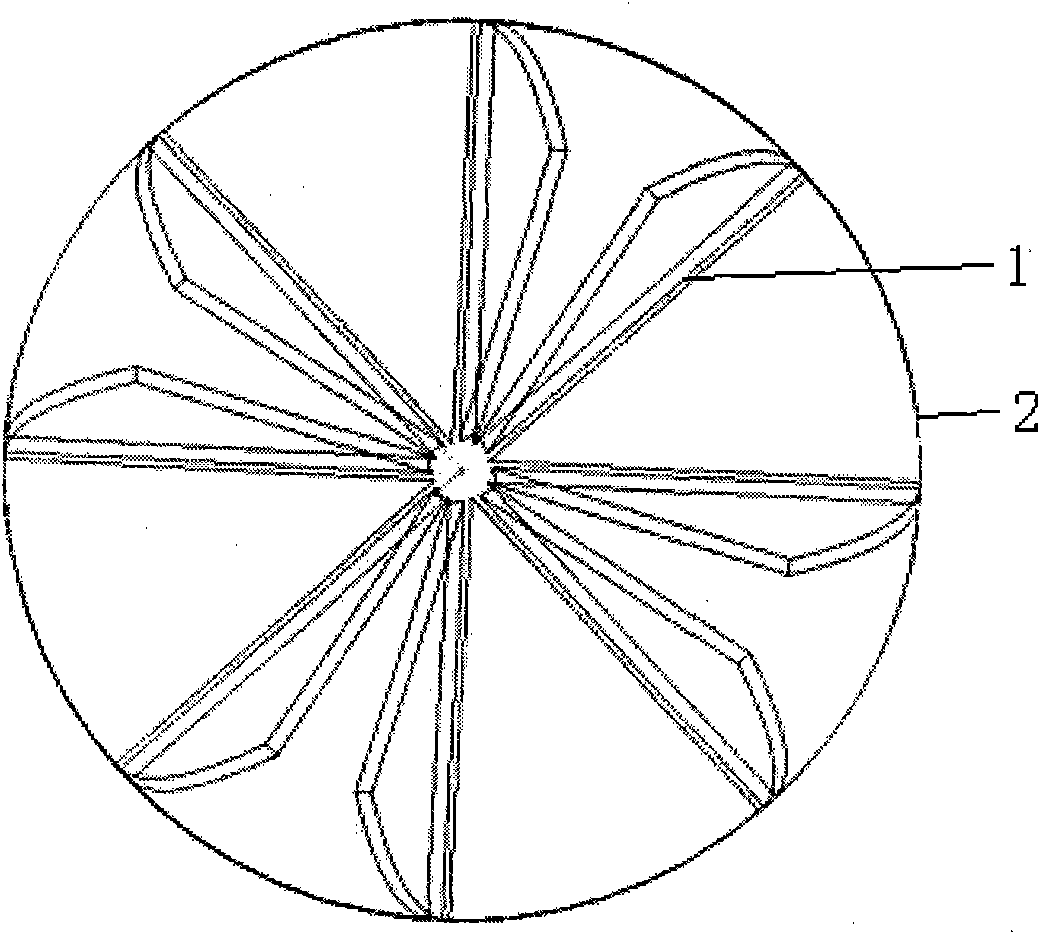

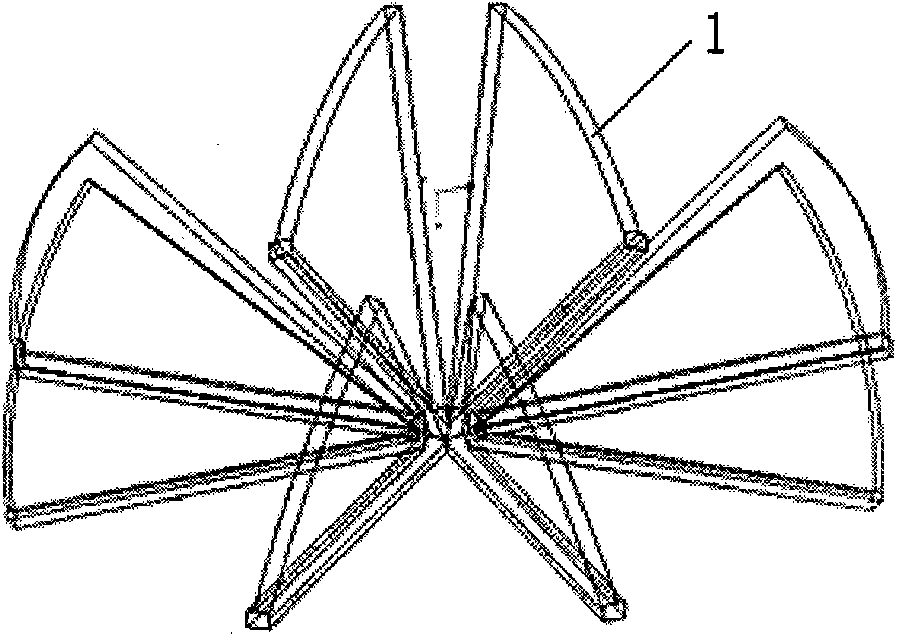

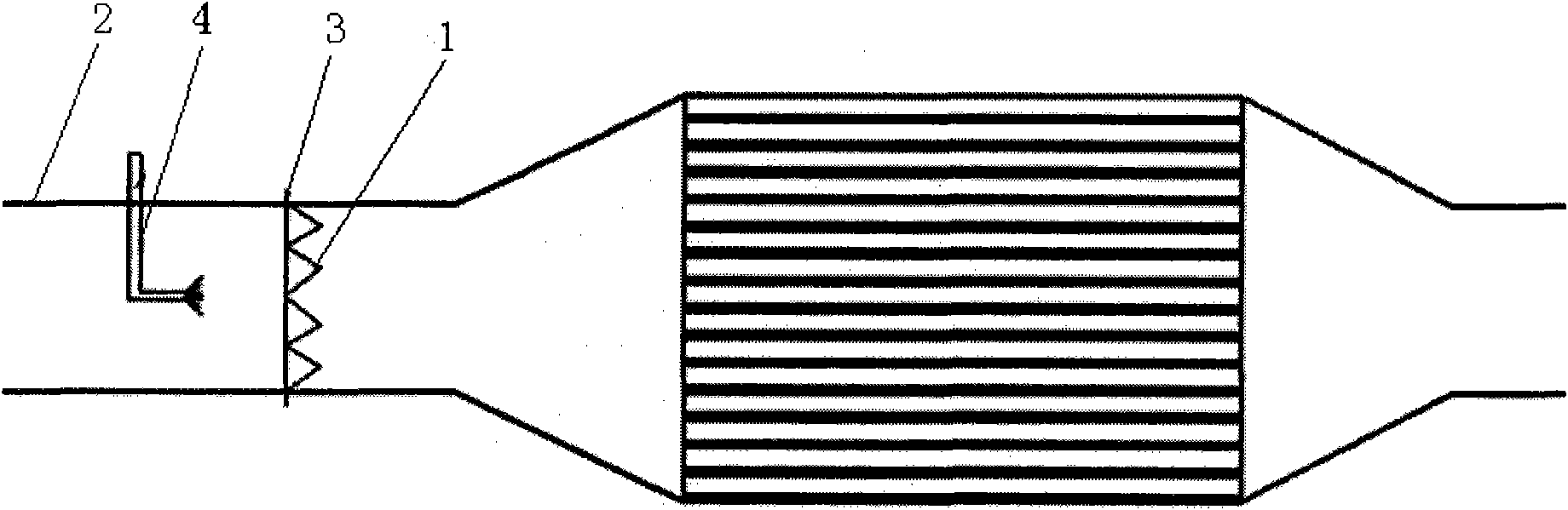

Image

Examples

Embodiment

[0020] An experiment was carried out on a 4.5L diesel engine to compare the conversion efficiency of NOx under various working conditions when the urea mixing device was installed and when the urea mixing device was not installed. The test results show that installing a urea mixing device can increase the NOx conversion efficiency by about 5%-10% under the same working conditions. The test conditions are shown in Table 1.

[0021] Table 1 Comparative test of each working condition

[0022]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com