Distributed solar point focusing optical mirror heat pipe tracking and utilizing system

A solar heat pipe and solar tracking technology, applied in the field of solar energy utilization, can solve the problems of limited application, unresolved focus, and inability to achieve tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

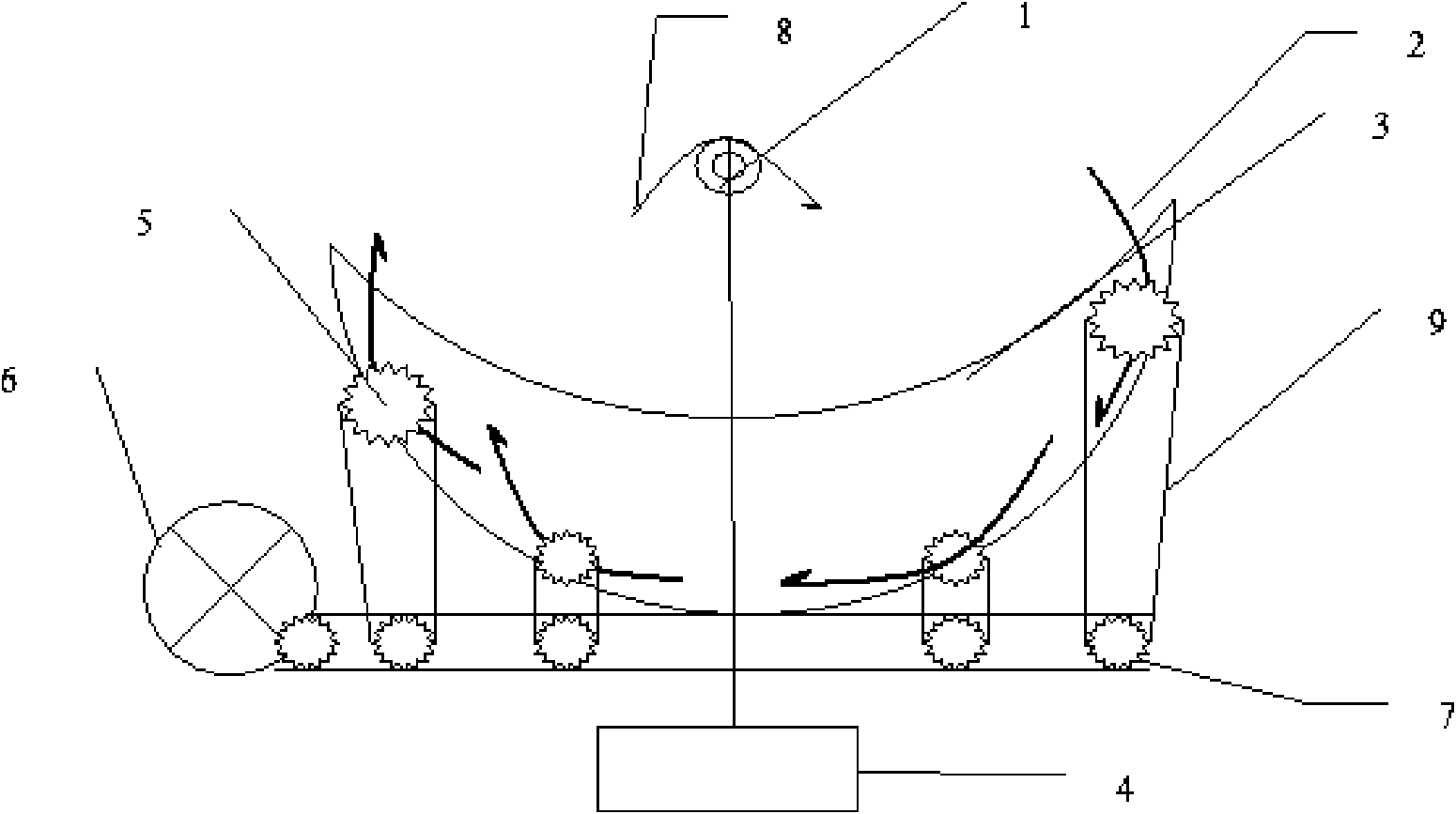

[0055] Single-axis tracking multi-parabolic mirror solar point focusing heat pipe utilization system (side view)

[0056] Book figure 1 It is a side view, and the solar mirror is a group of solar energy utilization systems composed of four parabolic reflectors (2), heat pipe utilization system (1), solar mirror bracket, etc.; the outside of the heat pipe is provided with a vacuum tube to insulate the heat preservation box; the parabolic mirror Set on a parabolic device (3), each parabolic mirror is provided with a rotating shaft (5), the solar mirror can rotate along the rotating shaft (5), and multiple solar mirrors realize solar energy through different movements Tracking, focusing solar light on the heat pipe at the same time, the four parabolic mirrors use the same drive system, the transmission mechanism is a gear set, different solar mirrors have different gear teeth, so that different speeds can be used to drive different solar mirrors for movement . Distributed solar...

Embodiment 2

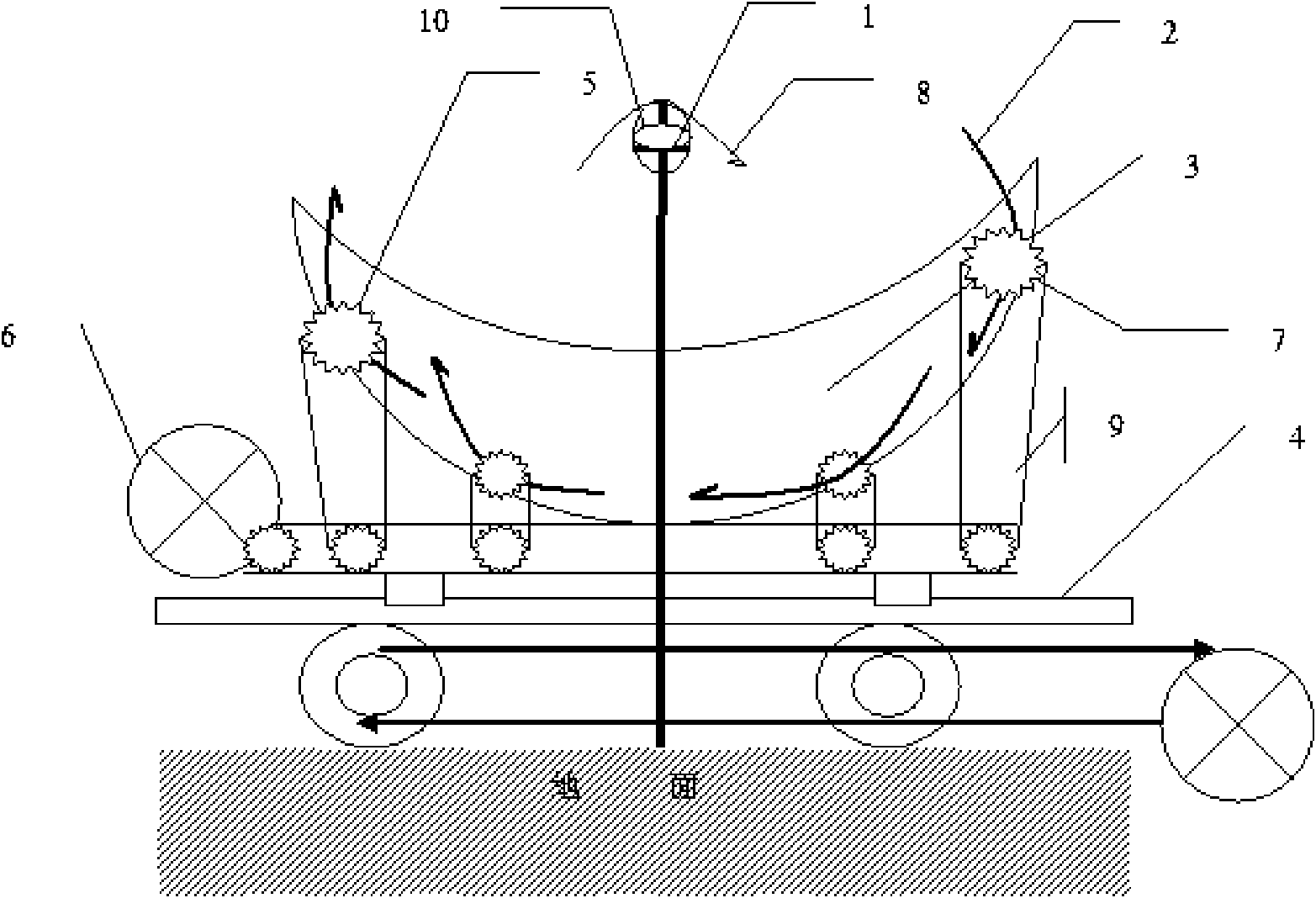

[0058] Two-axis tracking multi-parabolic mirror solar point focusing heat pipe utilization system (side view)

[0059] Book figure 2 It is a side view, and the solar mirror is a group of solar energy utilization systems composed of four parabolic reflectors (2), heat pipe utilization system (1), solar mirror bracket, etc.; the outside of the heat pipe is provided with a vacuum tube to insulate the heat preservation box; on the building and remain stationary; the parabolic mirror is arranged on a parabolic device (3), and a rotating shaft (5) is arranged on each parabolic mirror, and the solar mirror can rotate along the rotating shaft (5). Each solar mirror tracks the solar energy through different movements, and at the same time focuses the solar light onto the heat pipe. The four parabolic mirrors use the same drive system, and the transmission mechanism is a gear set. Different solar mirrors have different numbers of gear teeth, so they can be used Different rotational sp...

Embodiment 3

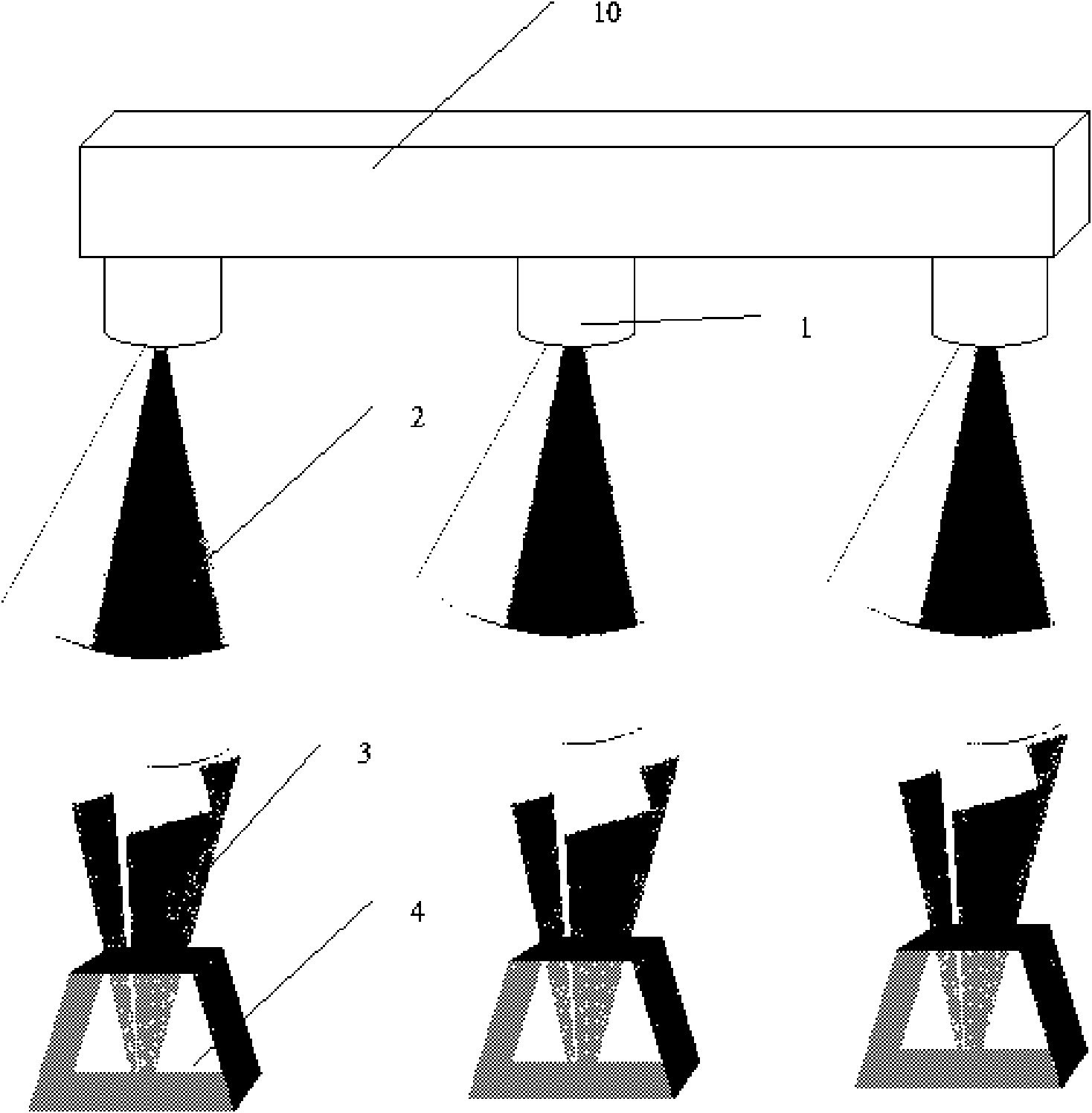

[0060] Embodiment 3. Heat pipe hot spot focused heat pipe utilization system

[0061] Such as image 3 , this case is a solar energy utilization system composed of multiple point-focusing reflectors set on the building, the solar mirror (2) samples point-focused parabolic reflectors, and each point-focused reflector is set on the tracking system (3) , the tracking system is set on the tracking bracket (4), each solar mirror focuses the solar energy on a heat pipe utilization system (1), multiple heat pipes realize the transmission of heat energy through the heat pipe heat transfer system (10), and multiple heat pipe evaporation ends are set The light-to-heat conversion is realized on different point focusing systems, and together they form a whole heat pipe system to realize the transmission and utilization of heat energy. Setting the solar energy utilization of multiple groups in different buildings and ground areas can realize the point-focused utilization of solar energy i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com