Treatment method of poultry manure

A processing method and technology for poultry manure, which are applied in grain processing, drying of solid materials, furnaces, etc., can solve the problems of low bacterial content in poultry manure, and achieve the effects of good deodorization effect, high nutritional value and excellent deodorization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: A kind of poultry manure processing method, poultry manure is placed in the high-temperature negative-pressure airflow of 500 ℃, and then stirred to pulverize the poultry manure; Separate and discharge from the high-temperature negative-pressure air flow; the time for poultry manure to be kept in the high-temperature negative-pressure air flow should be such that the poultry manure is only heated to 95°C by the high-temperature negative-pressure air flow when discharging; During the process, when the temperature of the poultry manure itself reaches 70°C, the moisture inside the poultry manure can reach the boiling point and evaporate; the odor molecules inside the poultry manure can overflow from the poultry manure under the combined action of stirring and crushing and high-temperature negative pressure airflow Decomposed by pyrolysis.

Embodiment 2

[0025] Embodiment 2: A kind of poultry manure processing method, poultry manure is placed in the high-temperature negative-pressure airflow of 650 ℃, and then stirred to pulverize the poultry manure; Separate and discharge from the high-temperature negative-pressure air flow; the time for poultry manure to be kept in the high-temperature negative-pressure air flow should be such that the poultry manure is only heated to 105°C by the high-temperature negative-pressure air flow when discharging; During the process, when the temperature of the poultry manure itself reaches 80°C, the moisture inside the poultry manure can reach the boiling point and evaporate; so that the odor molecules inside the poultry manure can overflow from the poultry manure under the combined action of stirring and crushing and high-temperature negative pressure air flow. Decomposed by pyrolysis.

Embodiment 3

[0026] Embodiment 3: A kind of poultry manure processing method, poultry manure is placed in the high-temperature negative-pressure airflow of 600 ℃, and then stirred to pulverize the poultry manure; Separate and discharge from the high-temperature negative-pressure air flow; the time for poultry manure to be kept in the high-temperature negative-pressure air flow should be such that the poultry manure is only heated to 100°C by the high-temperature negative-pressure air flow when it is discharged; During the process, when the temperature of the poultry manure itself reaches 75°C, the moisture inside the poultry manure can reach the boiling point and evaporate; the odor molecules inside the poultry manure can overflow from the poultry manure under the combined action of stirring and crushing and high-temperature negative pressure air flow. Decomposed by pyrolysis.

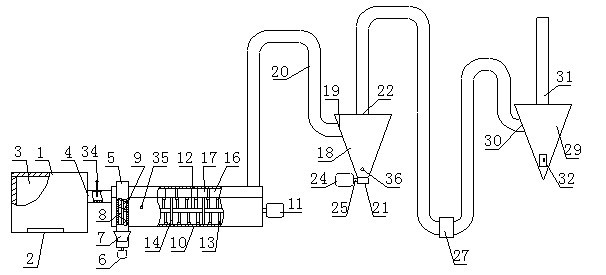

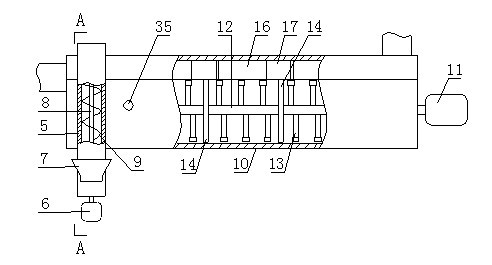

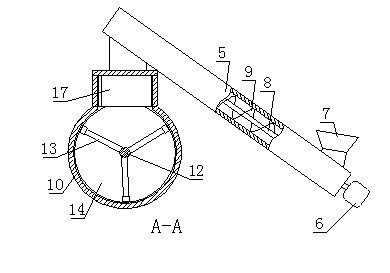

[0027] The method of the present invention will be further described in detail below in conjunction with a devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com