Omnibearing tilt sensor based on machine vision

A technology of tilt sensor and machine vision, applied in the direction of measuring inclination, instruments, measuring devices, etc., can solve problems such as complex mechanism, high requirements for use environment, single measurement parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

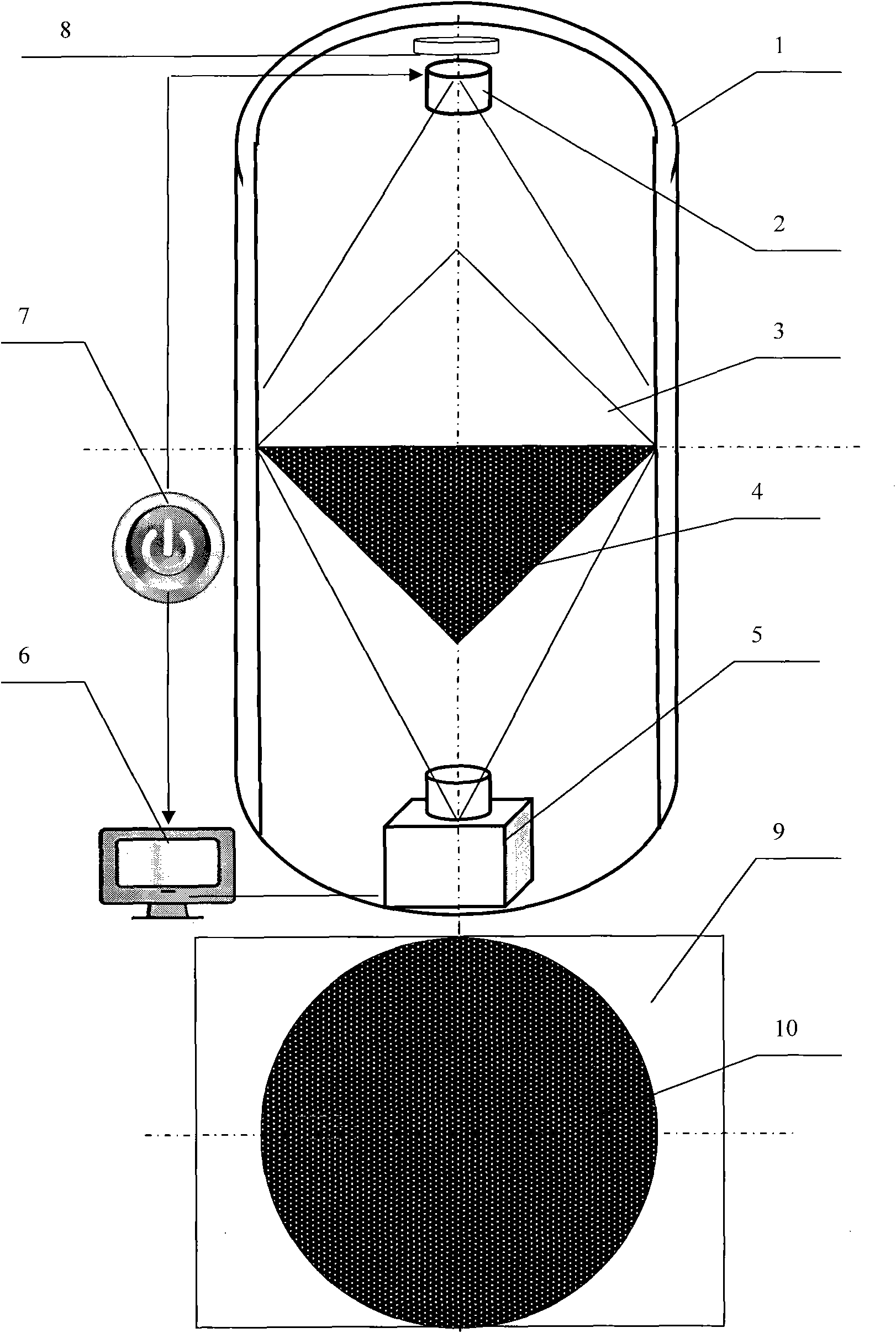

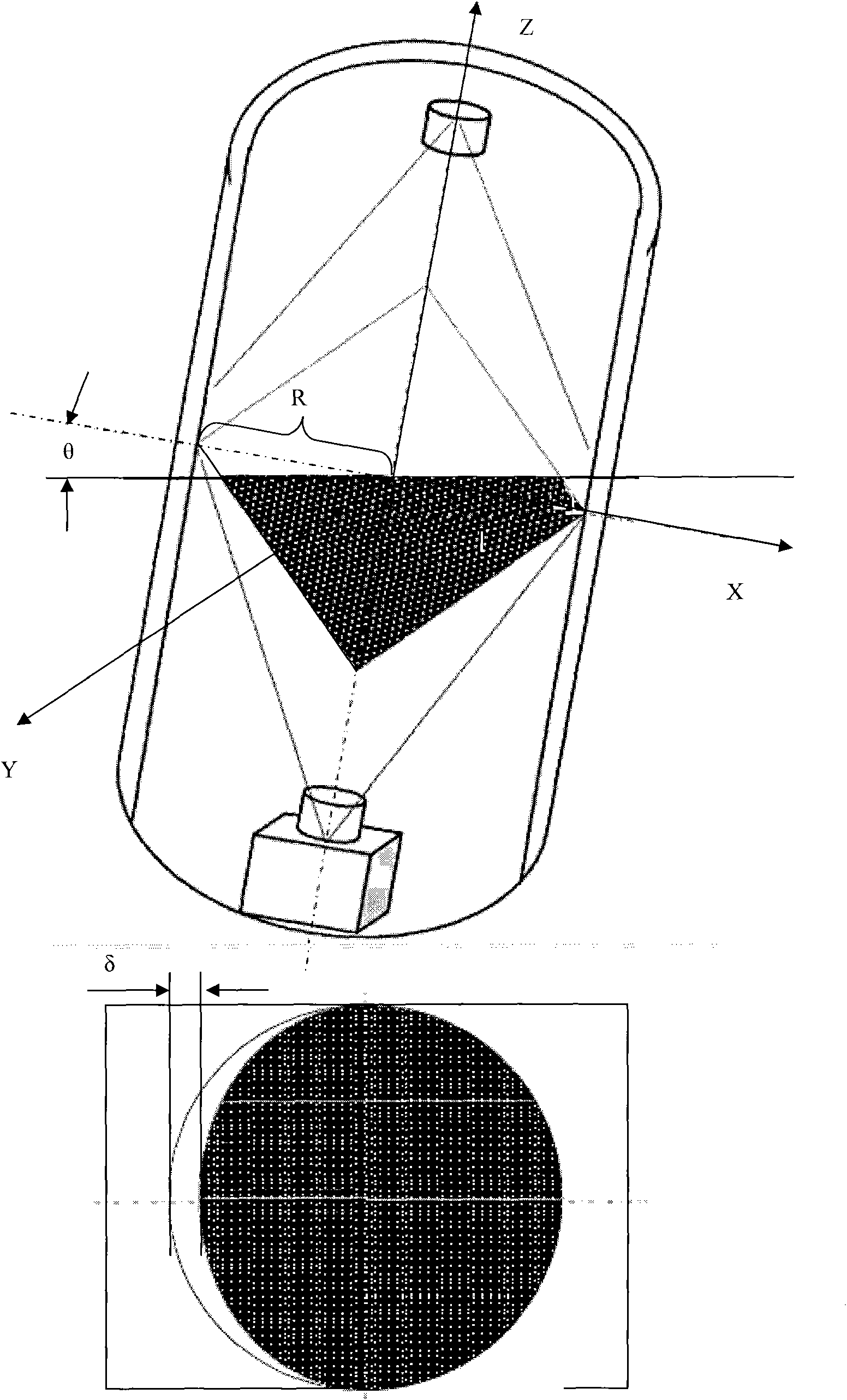

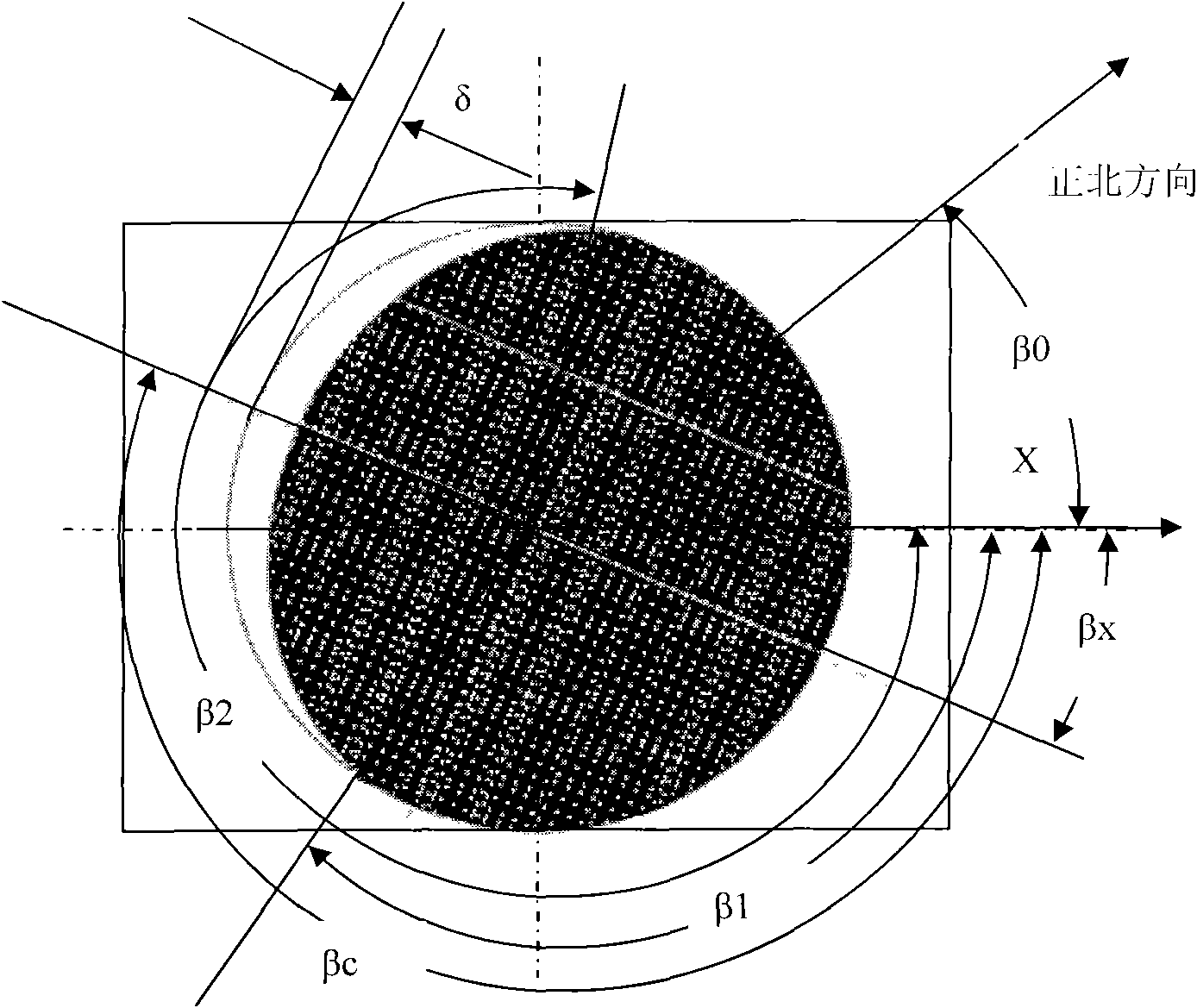

[0070] refer to Figure 1 to Figure 10 ,

[0071] An omnidirectional tilt sensor based on machine vision, including an omnidirectional tilt sensor housing 1, an LED lighting source 2, a transparent cone container 3, an opaque liquid 4, a camera 5, an embedded system 6, a power supply 7 and a compass 8, Described power supply 7 supplies power to described lighting source 2 and described embedded system 6, and described embedded system 6 supplies power to described camera 5 through USB interface, and described transparent cone container 3 is made of Two cones of the same size are combined into a closed container in a back-to-back manner; the transparent cone container 3 is fixed in the middle of the omni-directional tilt sensor housing 1, the LED lighting source 2 is fixed in the upper part, and the LED lighting source 2 is fixed in the lower part. The camera 5 is fixed; the LED lighting source 2 emits white light facing the center of the transparent cone container 3 downwards,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com